I have always found “The Good Roosevelt” to be a refreshing kind of guy. So I thought I would share some of the things that I found on the net I hope that you like this!

Ker

As you an see the Old Boy really got around.

Since he is the only American so far to have been awarded the Presidency of the United States, The Nobel Peace Prize and the Medal of Honor.

(His Son -Theodore Jr got his for his actions as a Brigadier General on D Day at Normandy. Generals do not usually get that medal at that rank by the way.)

Roosevelt’s 1903 Springfield Rifle – The later it belonged to Kermit Roosevelt, Theodore Roosevelt’s son

I just wish we had more like him around!

I will post some more stuff about him later on.

Thanks for your time on this!

Grumpy

Now this is what I call a Lady /REAl Woman. Who could probably easily take care of herself if need be.

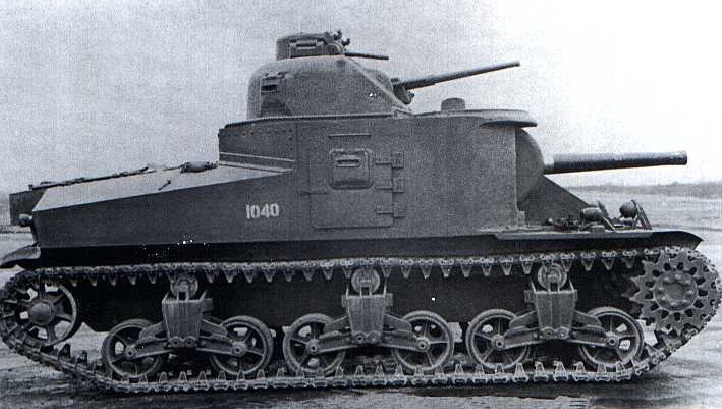

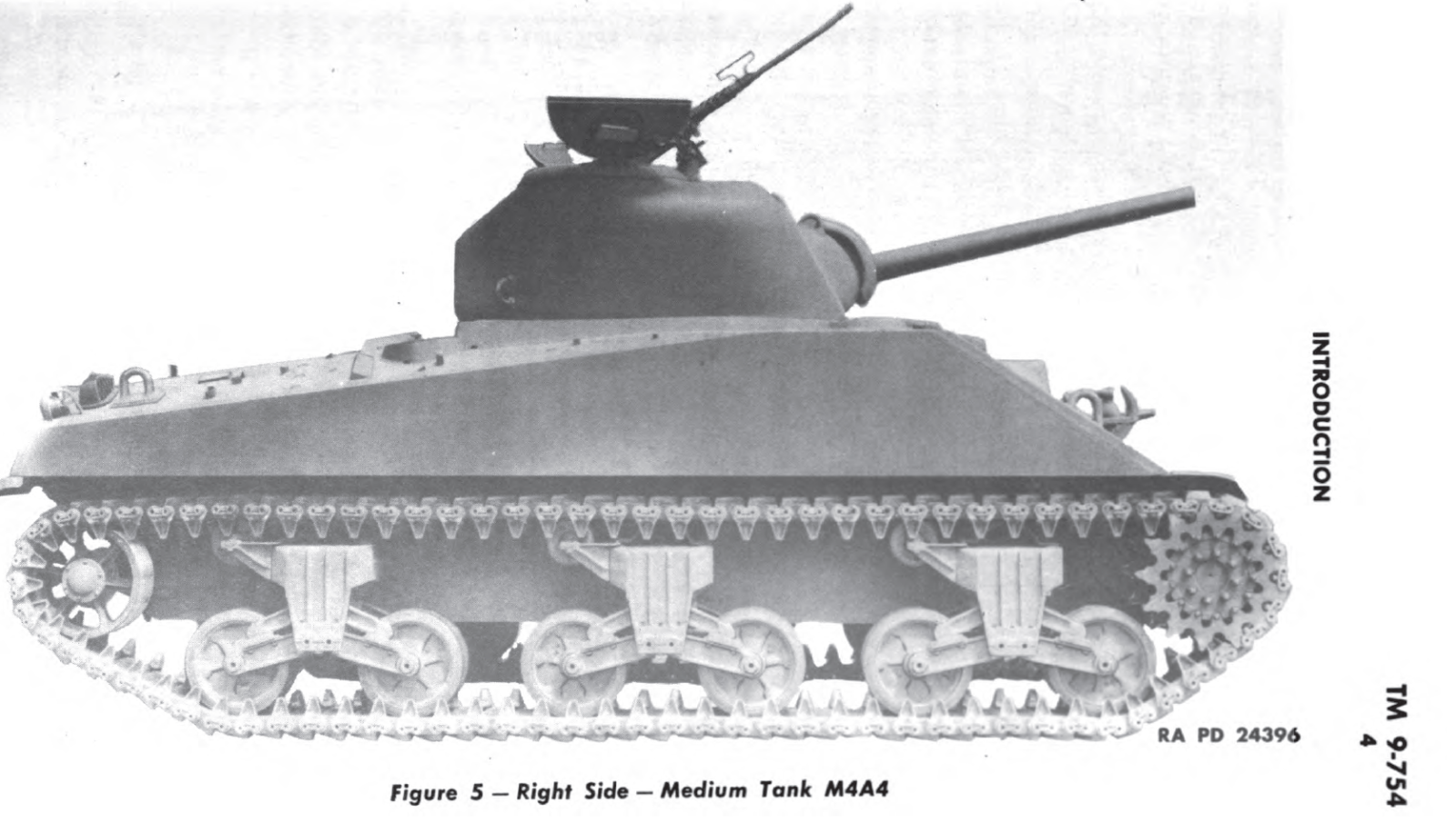

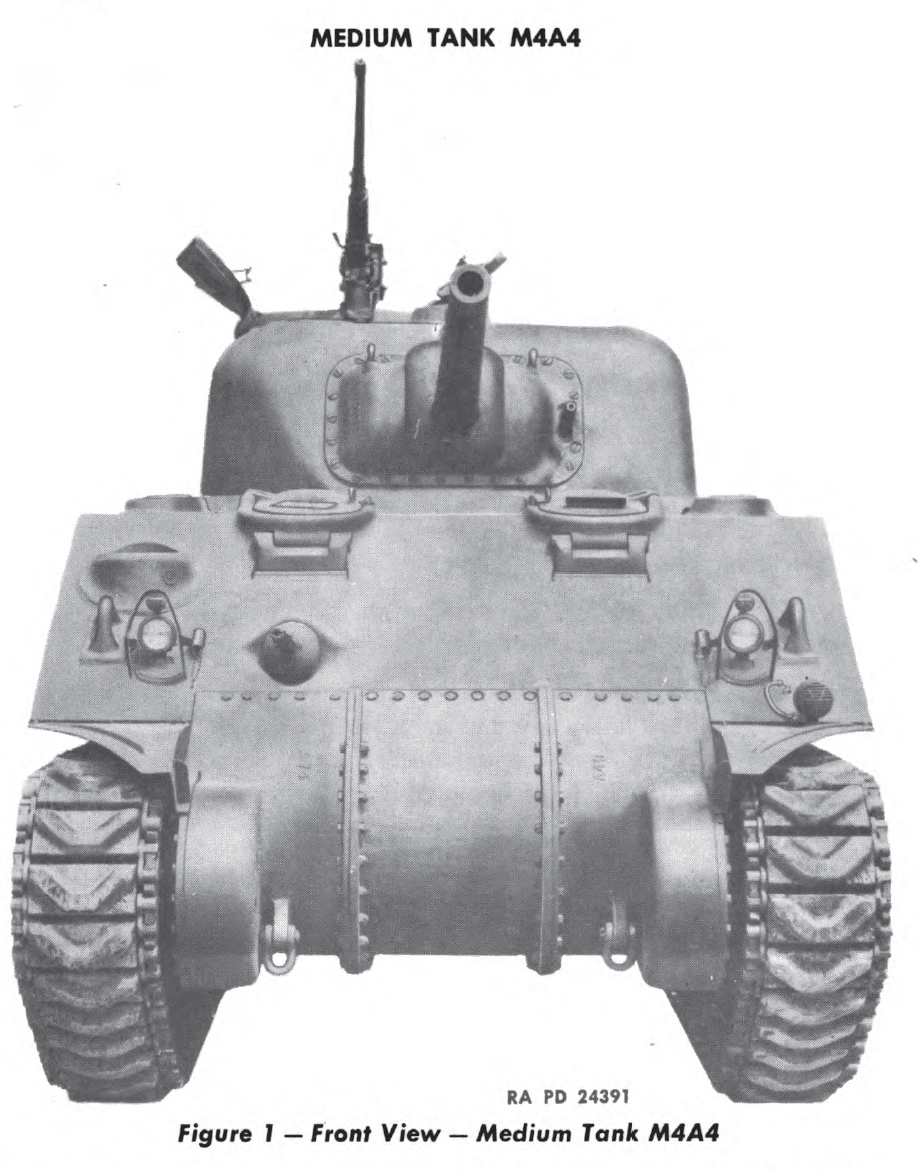

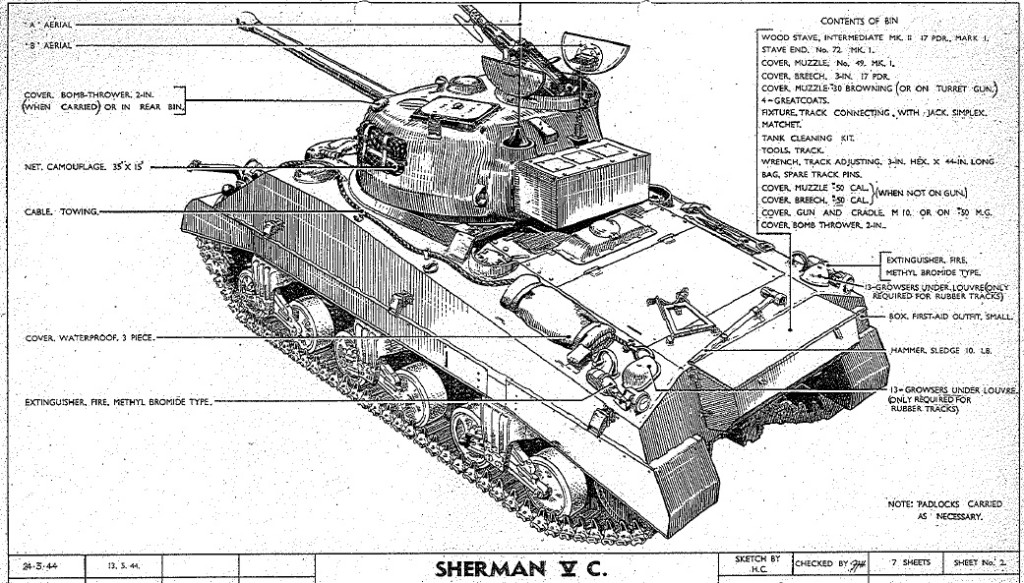

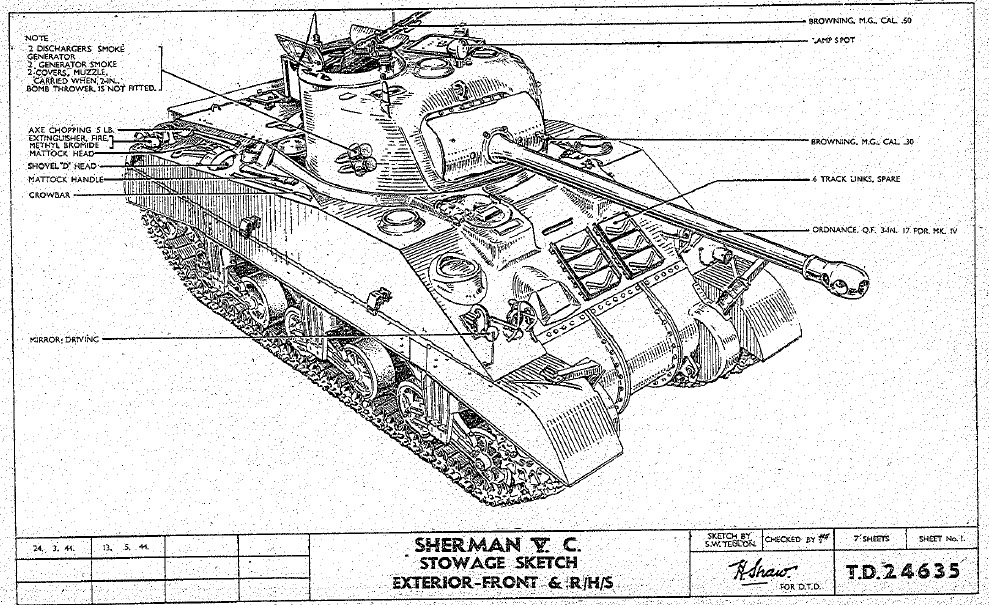

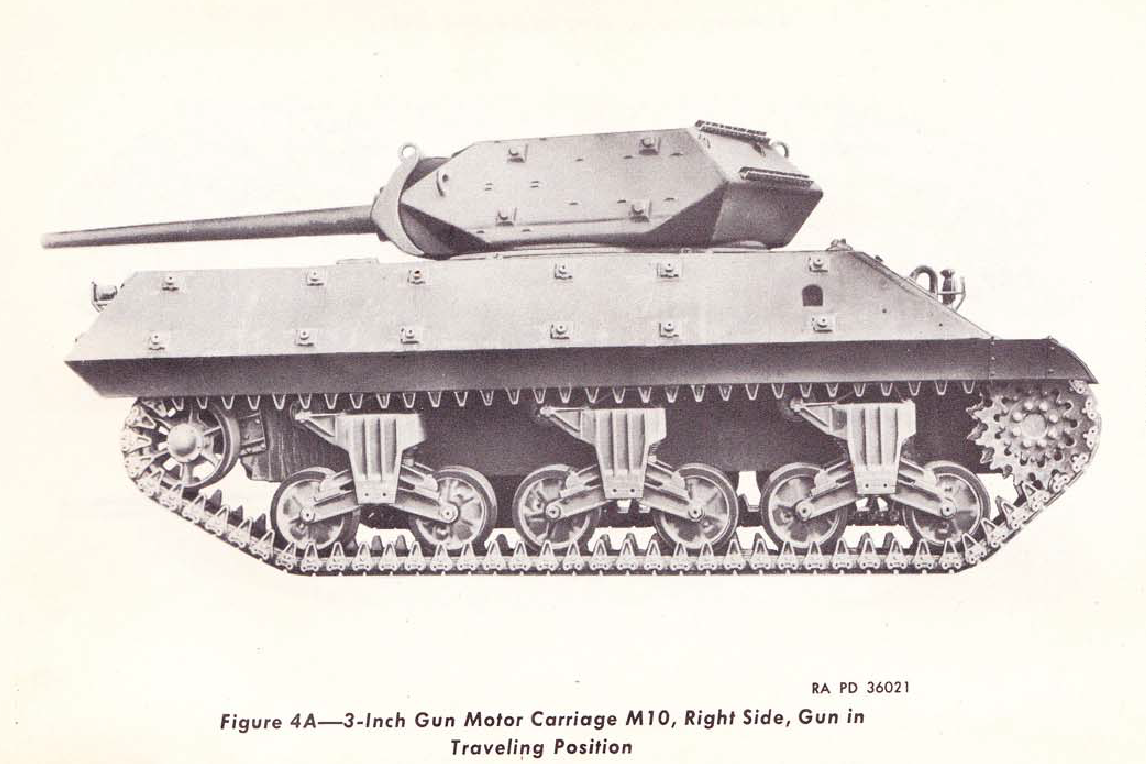

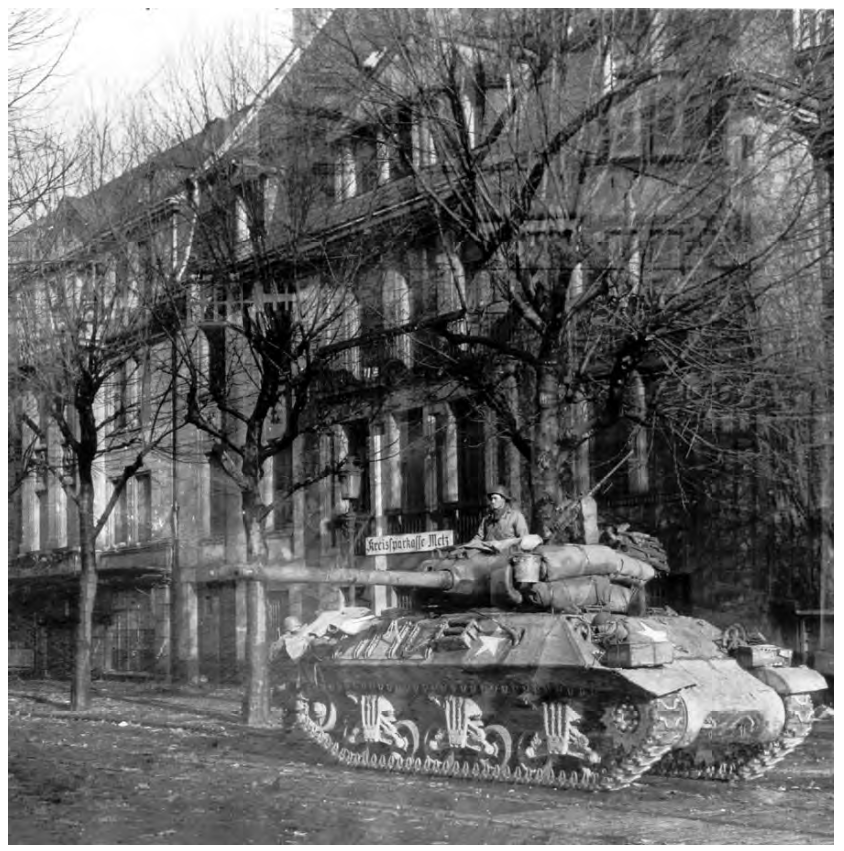

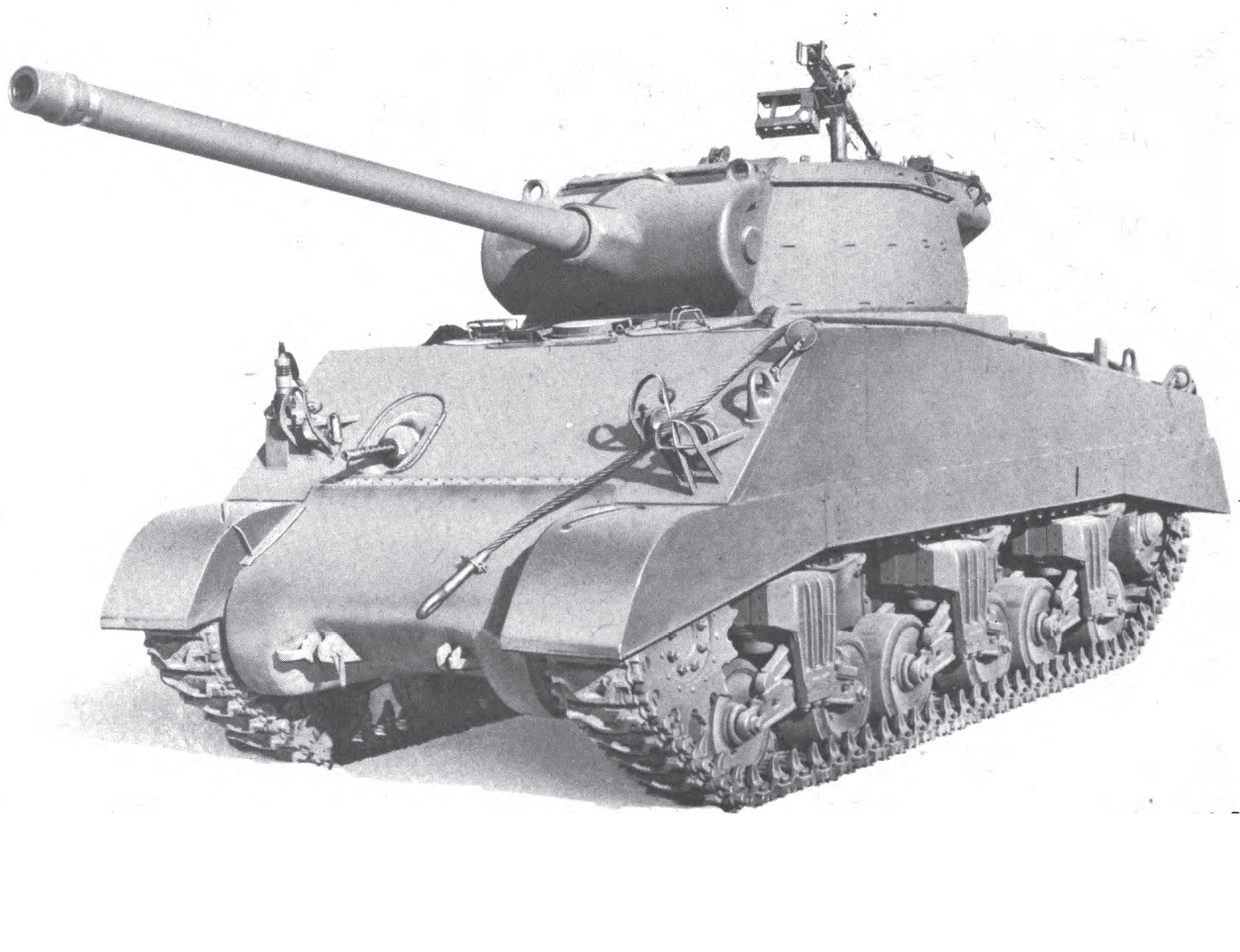

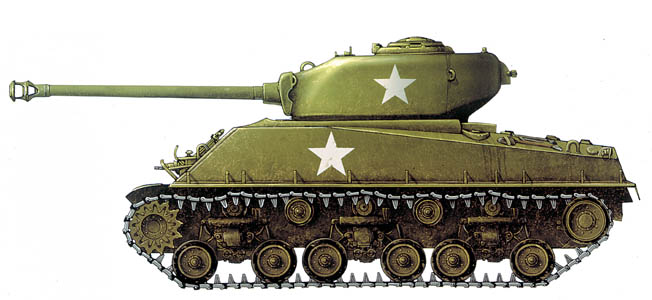

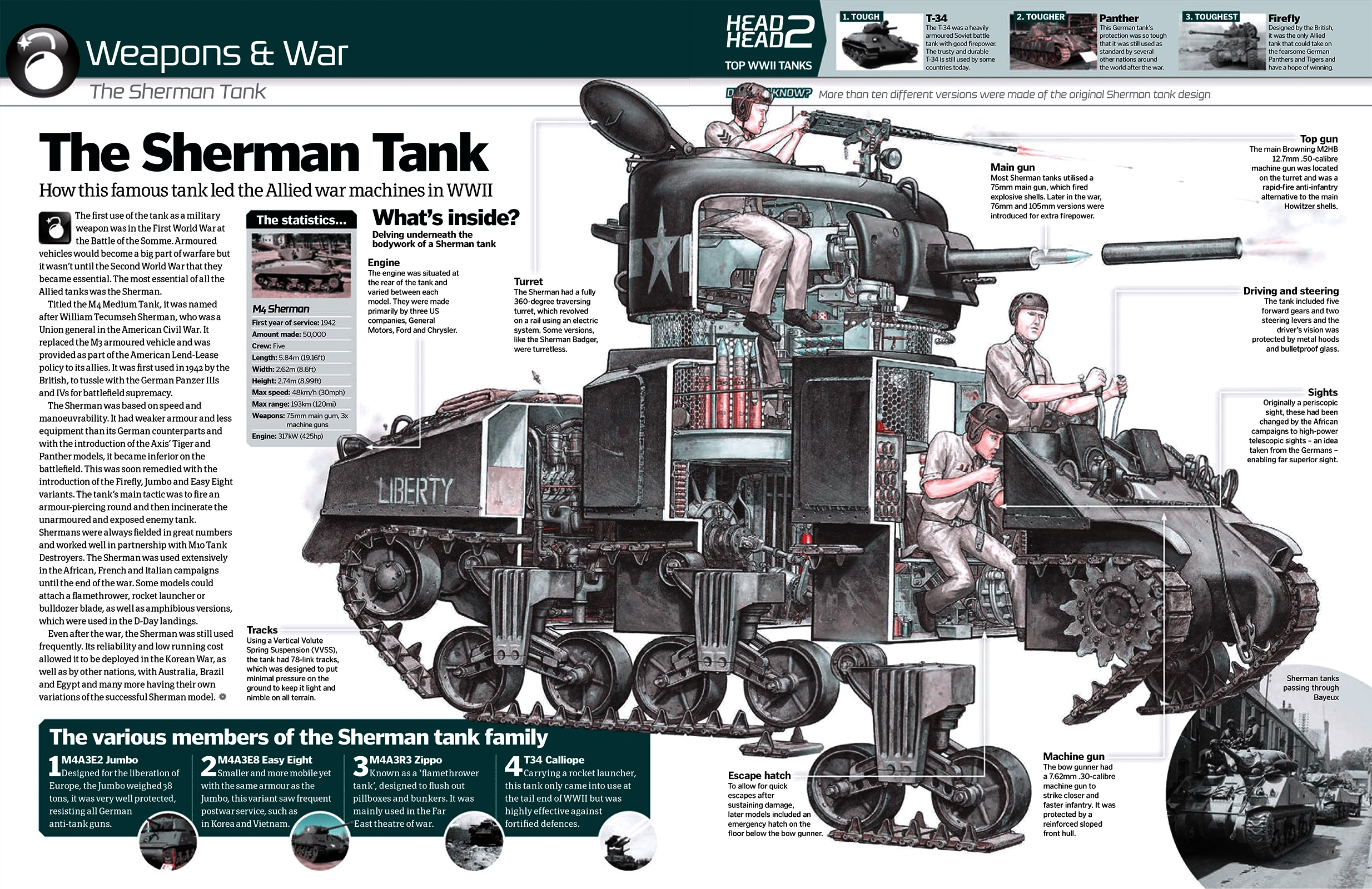

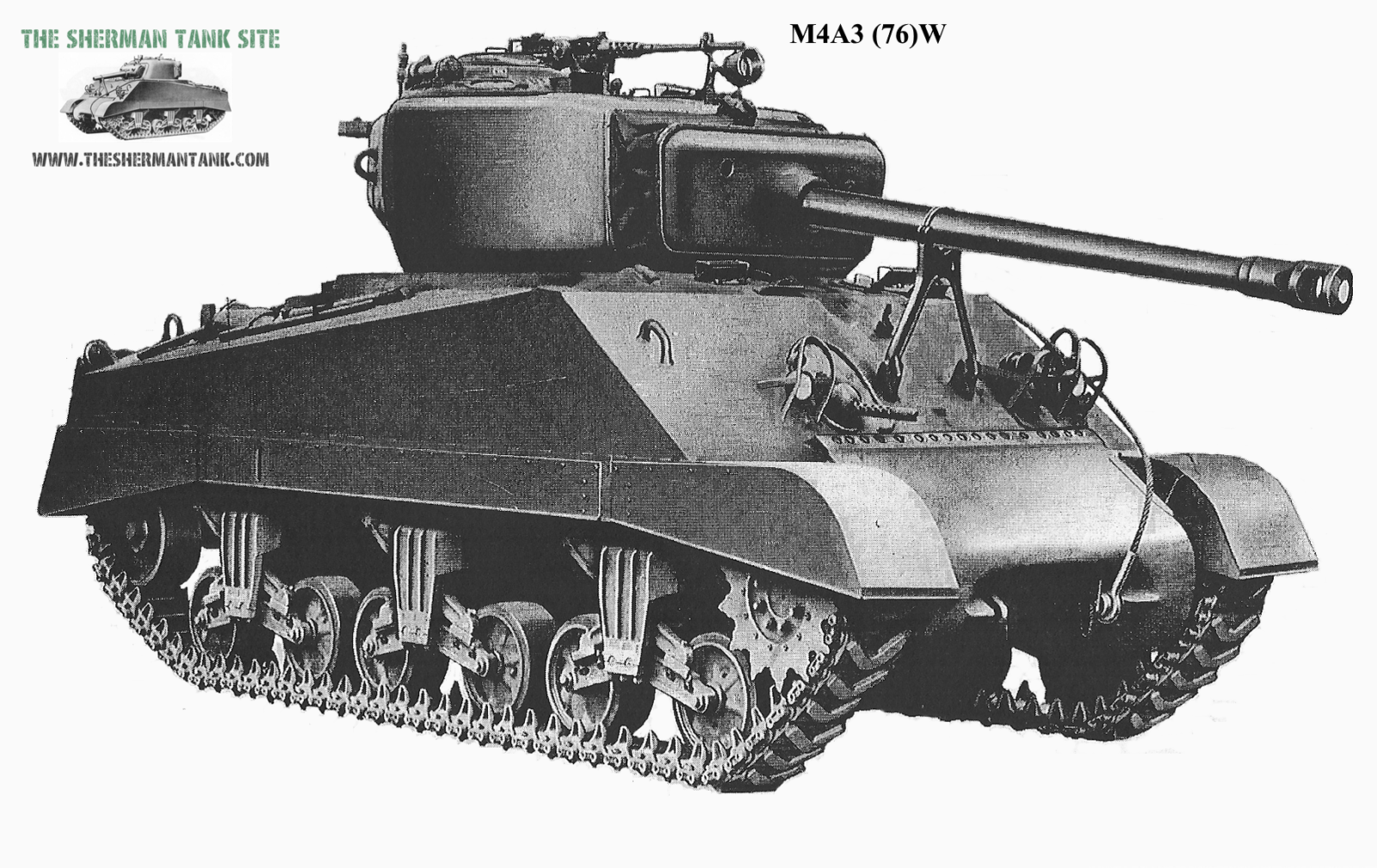

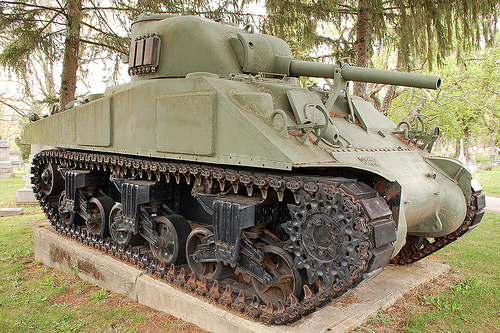

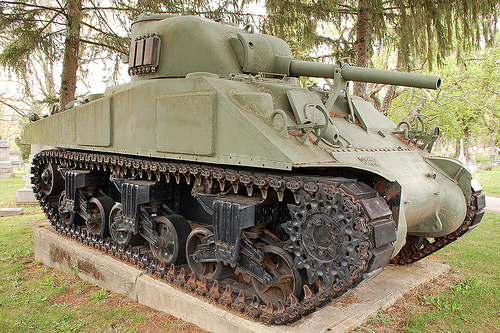

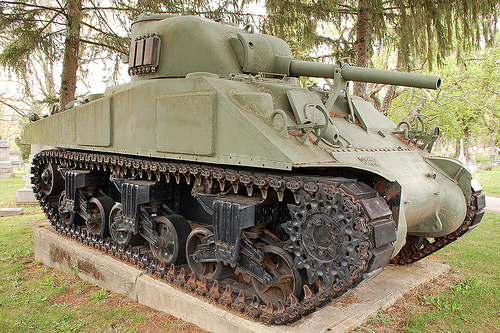

The Sherman Tank

Now I was assigned to a Armor Cavalry Regiment. When I was in the National Guard. So maybe I know a thing or two about Tanks.

As to the Sherman Tank. My hat is really off to those guys that rode in them during WWII & Korea. They really had a pair of solid brass Testicles.

Here are a few things that I learned about Armored Fighting Vehicles. They are hot, smelly, greasy, loud and blind.

Now by saying blind. When you are buttoned up inside of one. Really only the Driver and the Track Commander (The TC) can see out either by sticking their head out of the hatch*. Or by using his periscope. Yes tanks have periscopes.

*By the way a good Sniper will just loves this. He & his spotter will be looking mighty hard for you for this point.

Another thing that is mighty important to Tankers is that of TEAMWORK! As the crew thinks like a team or else.

How a tank is killed in Modern Combat.

Now everyone thinks that a Tank is invulnerable.

Trust me it isn’t !

So here are some of the things that Track Folks just hate with a passion.

The Bad Guys Tank

Anti Tank Guns

Close Air Support

Hand held Anti Tank Weapons like the Russian RPG

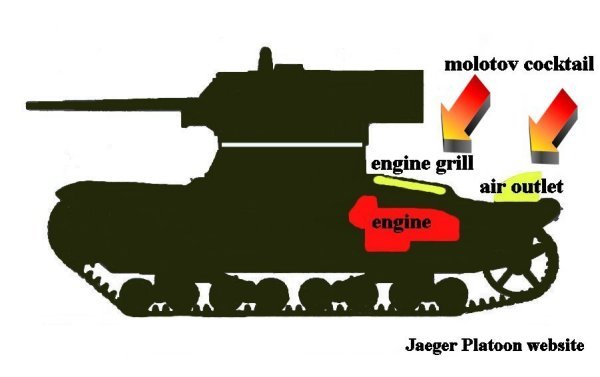

Crazy Folks with Molotov Cocktails

Or just throwing a Track in combat.

Does this look like fun or what!?! Especially when some pissed off at you folks are shooting at you.

Now if you want to see a fairly accurate film about the Sherman Tank in the ETO. You might want to see Fury.

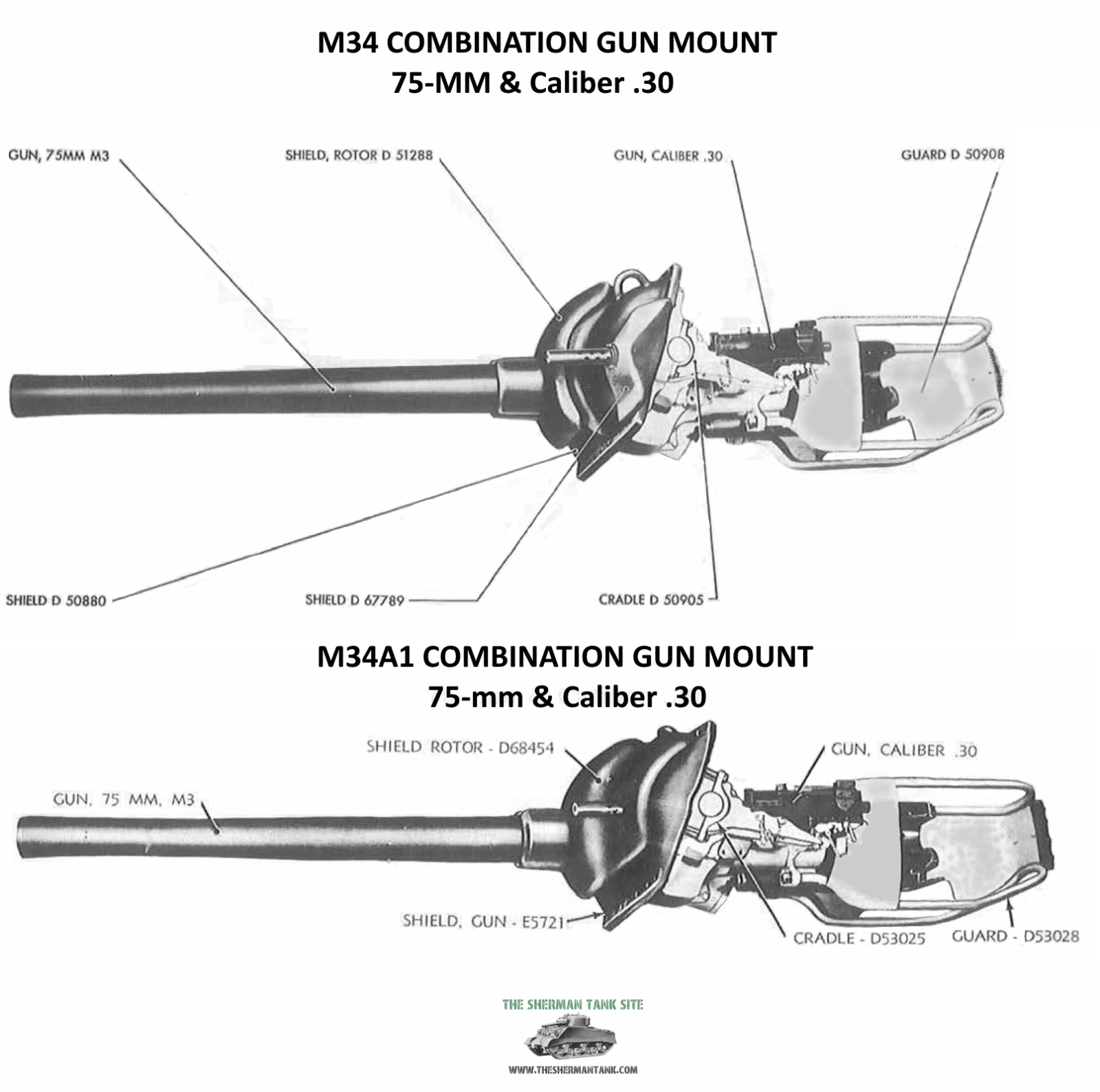

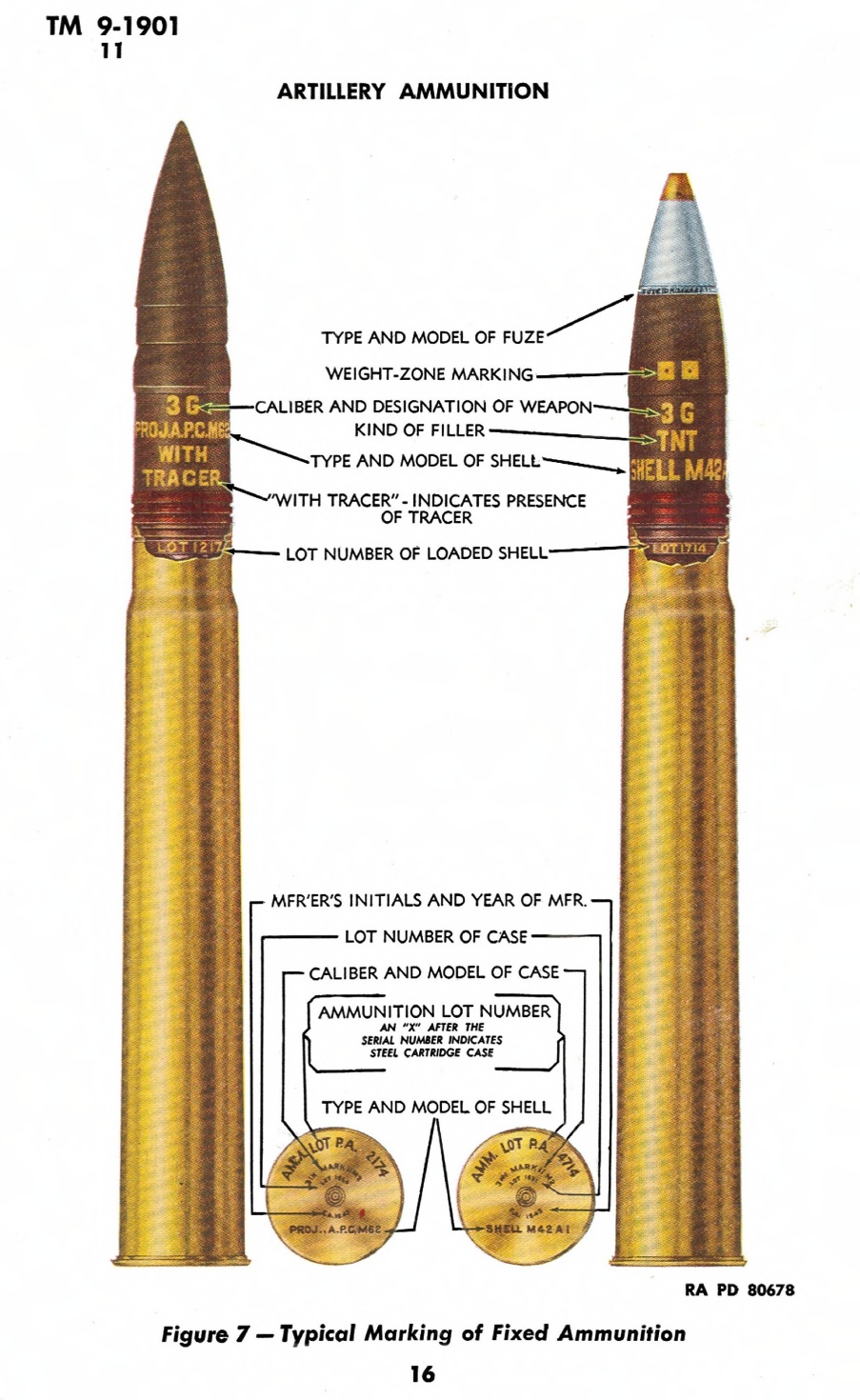

Now is is some more Technical info about the Sherman

Sherman Tank Site: News Post 12, pictures and cleaning them up, a lot of them.

Sherman Tank Site: News Post 12, things have been changing, its all behind the scenes.

Sherman Tank Site: News Post 12, things have been changing, its all behind the scenes.

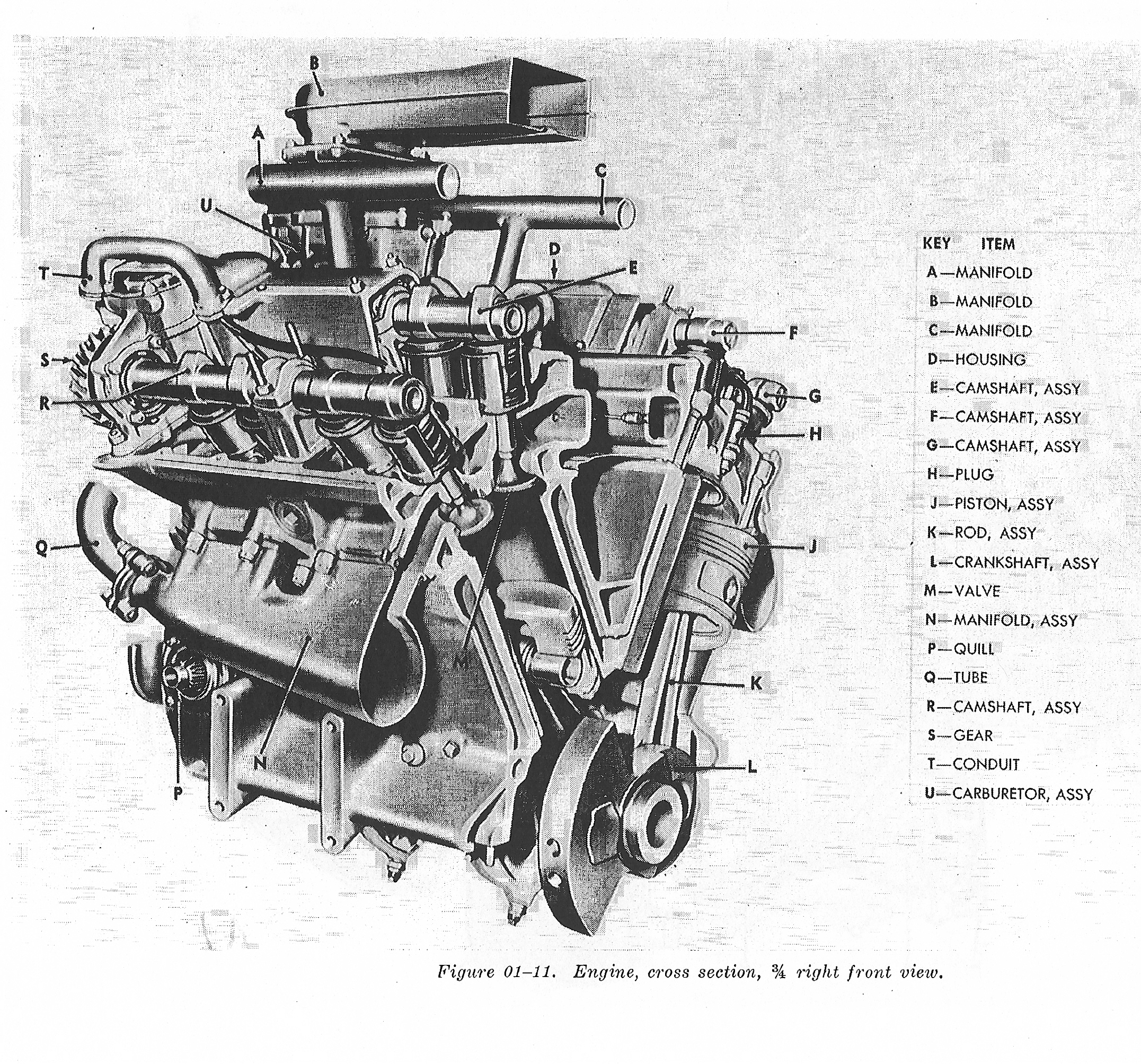

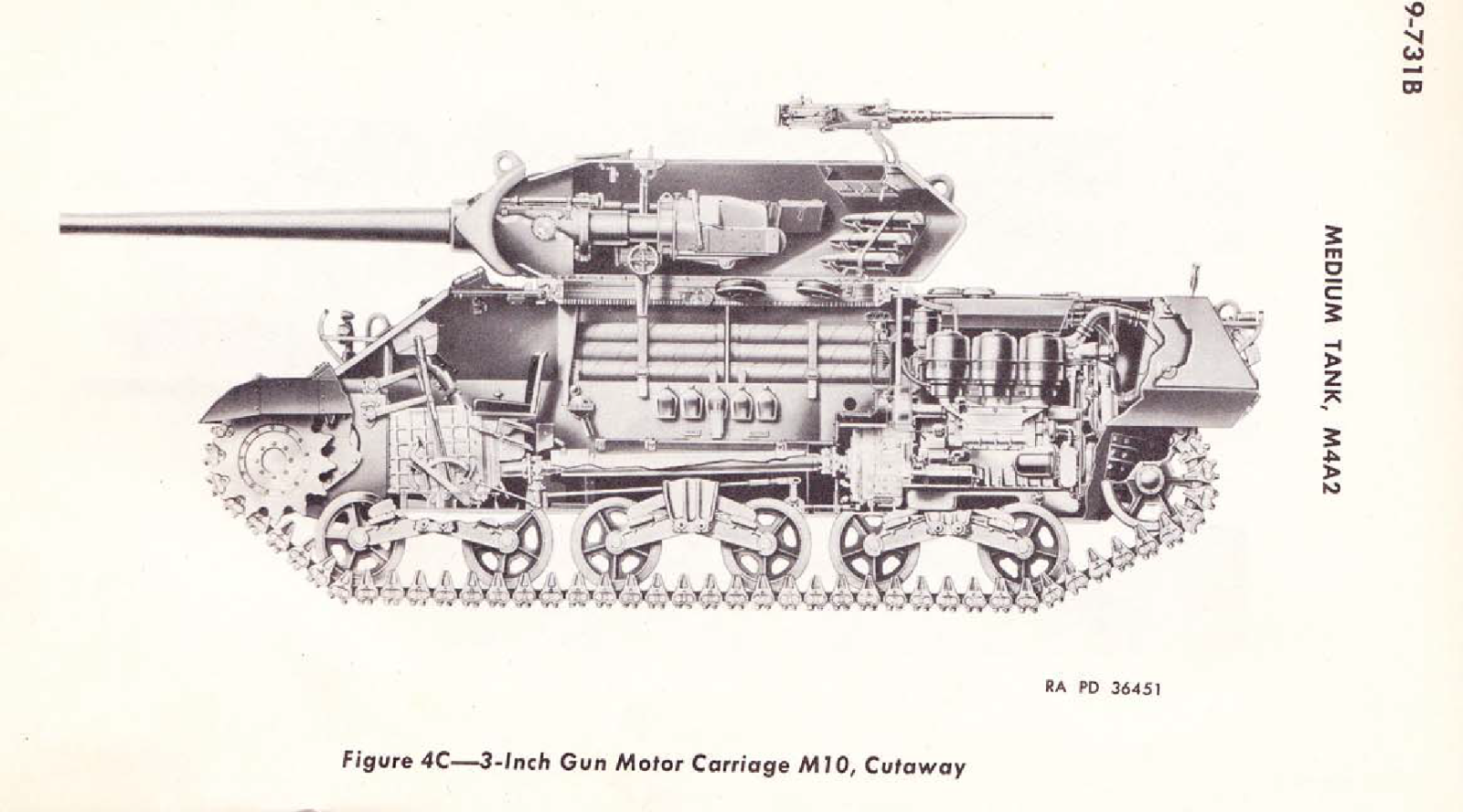

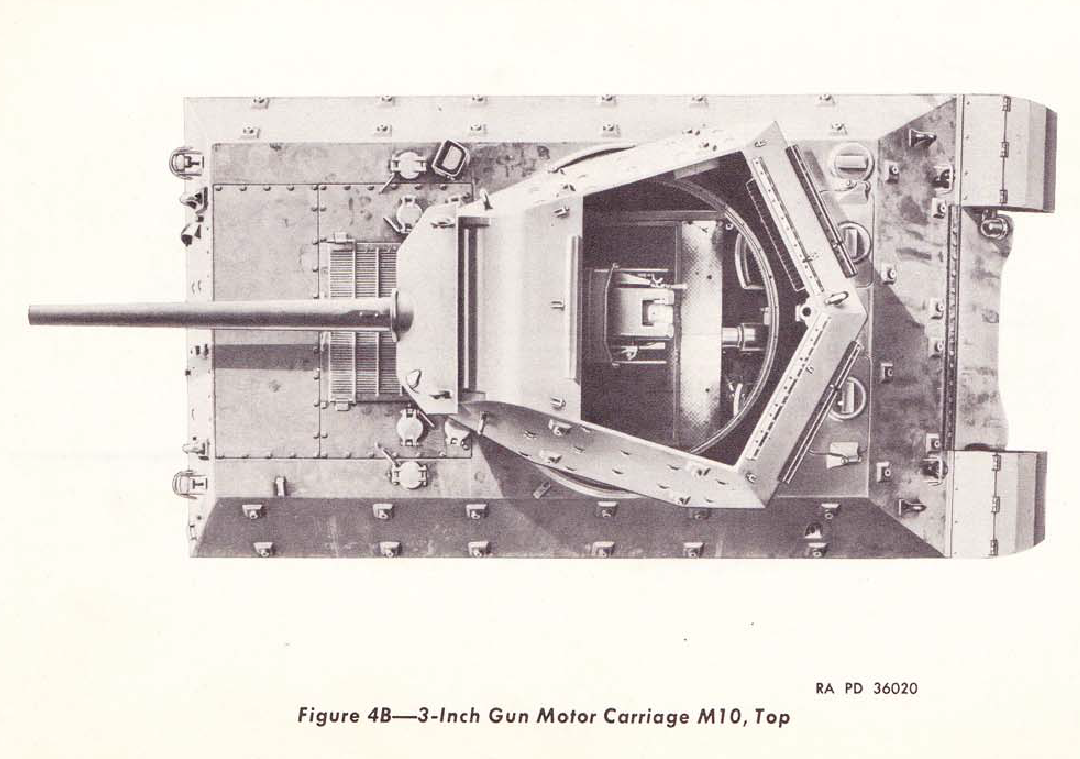

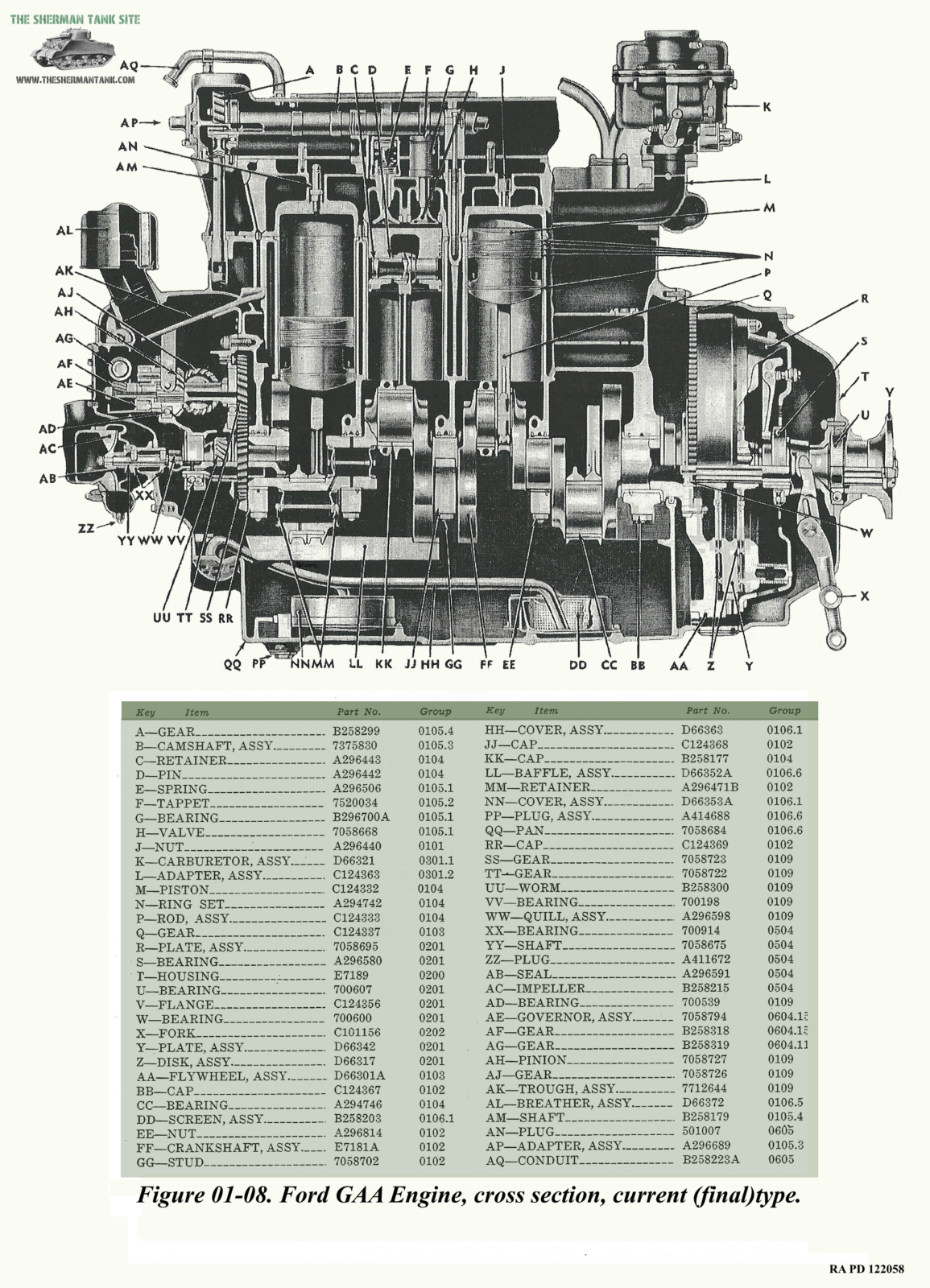

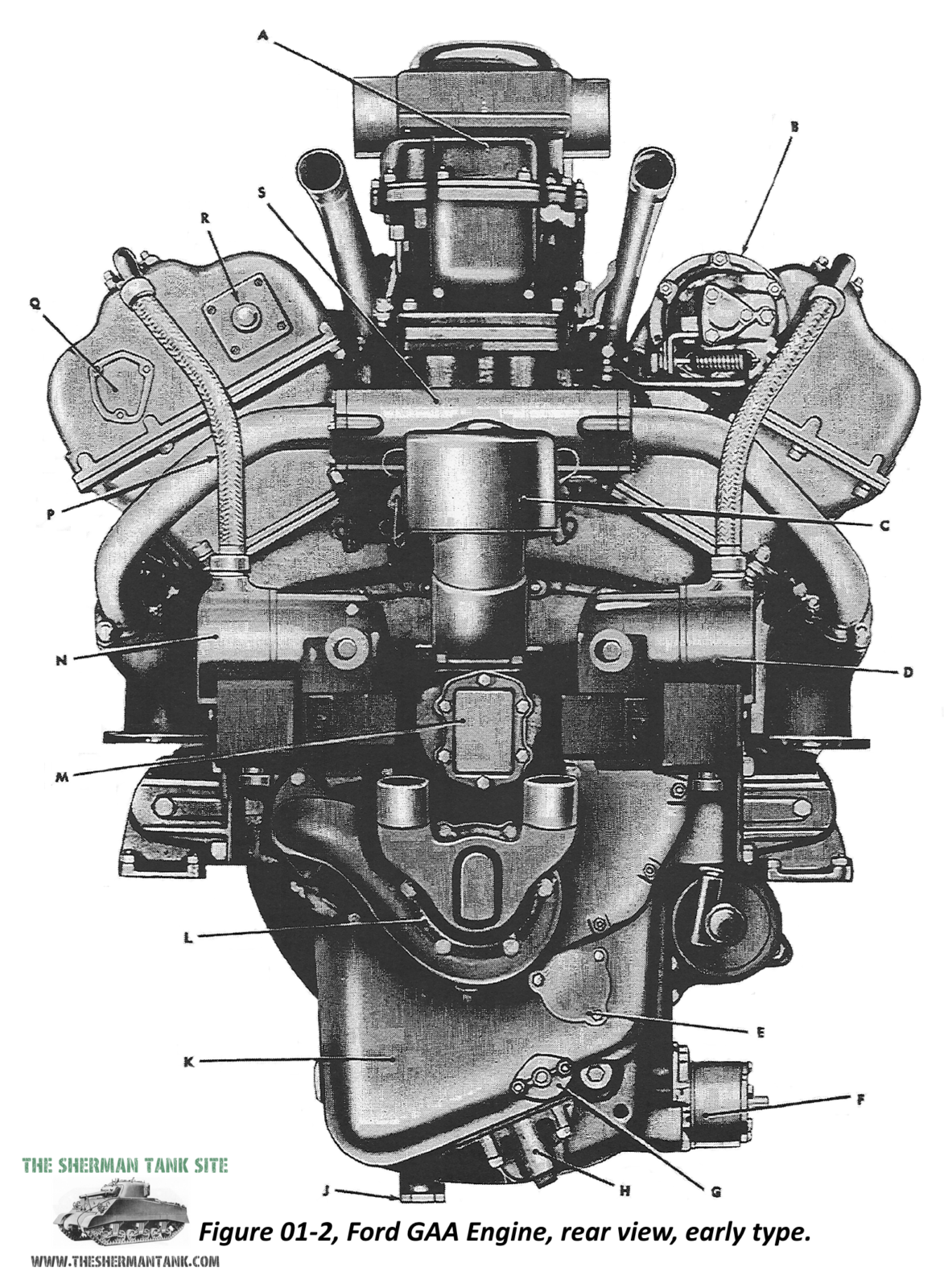

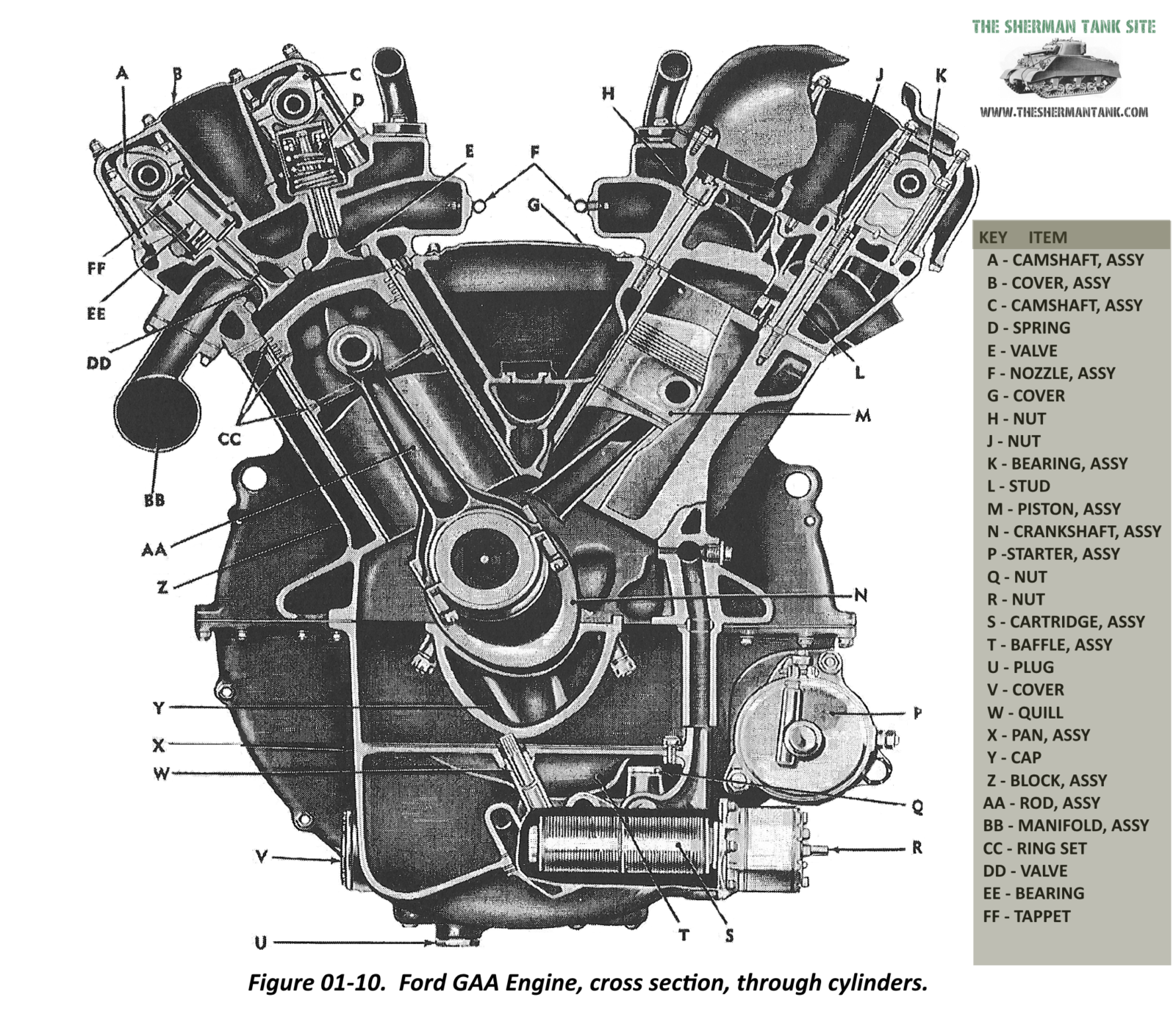

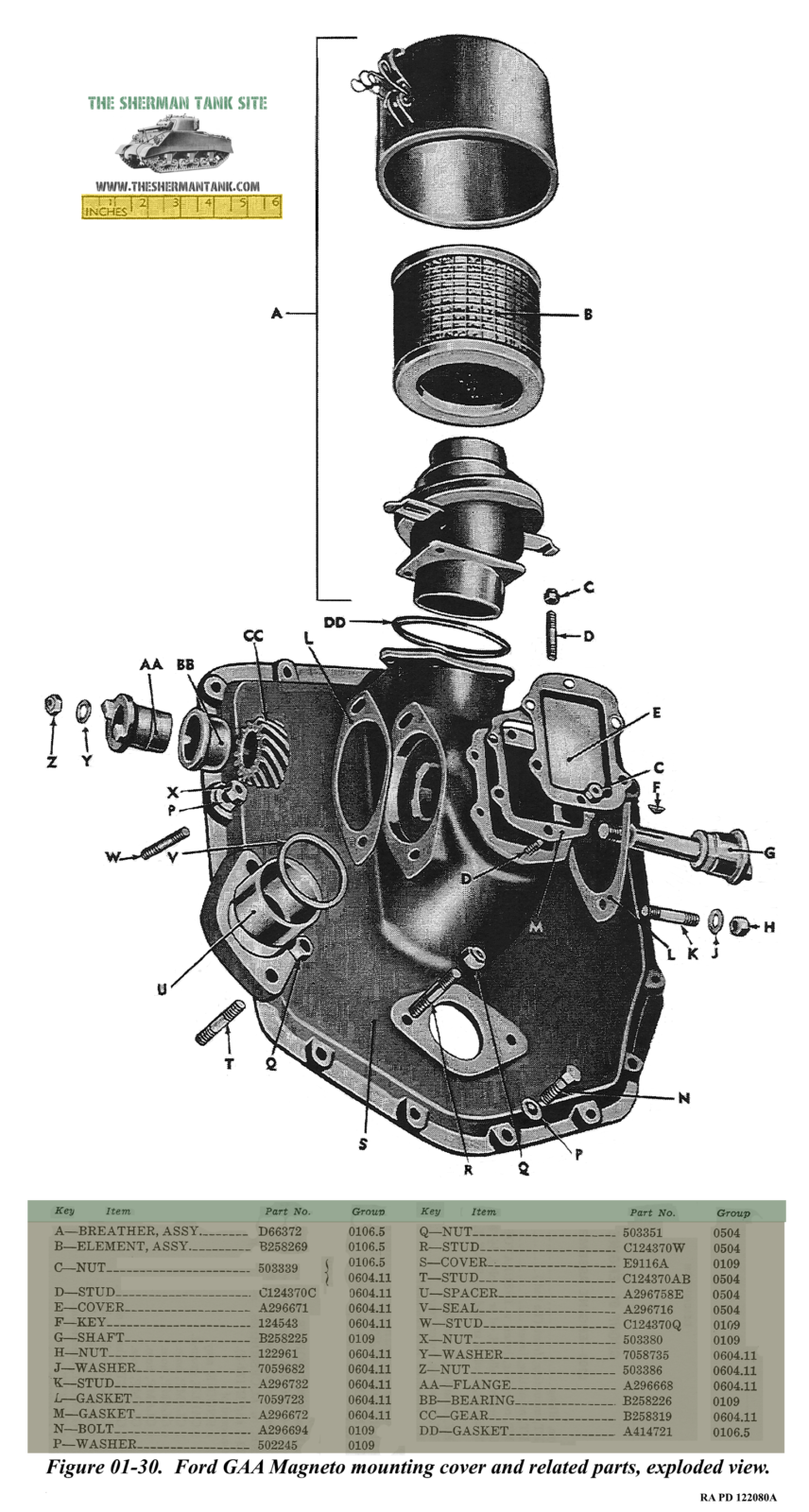

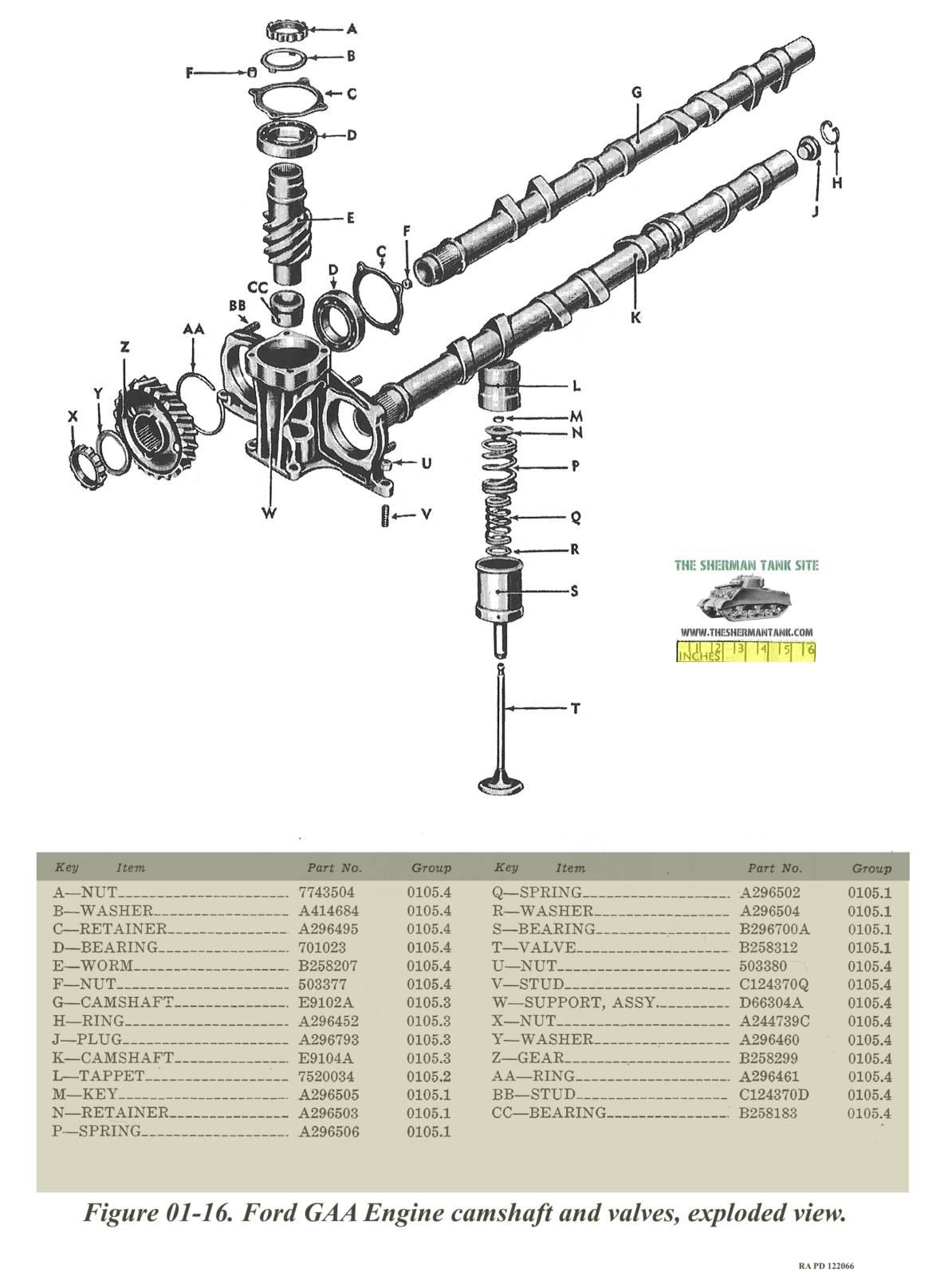

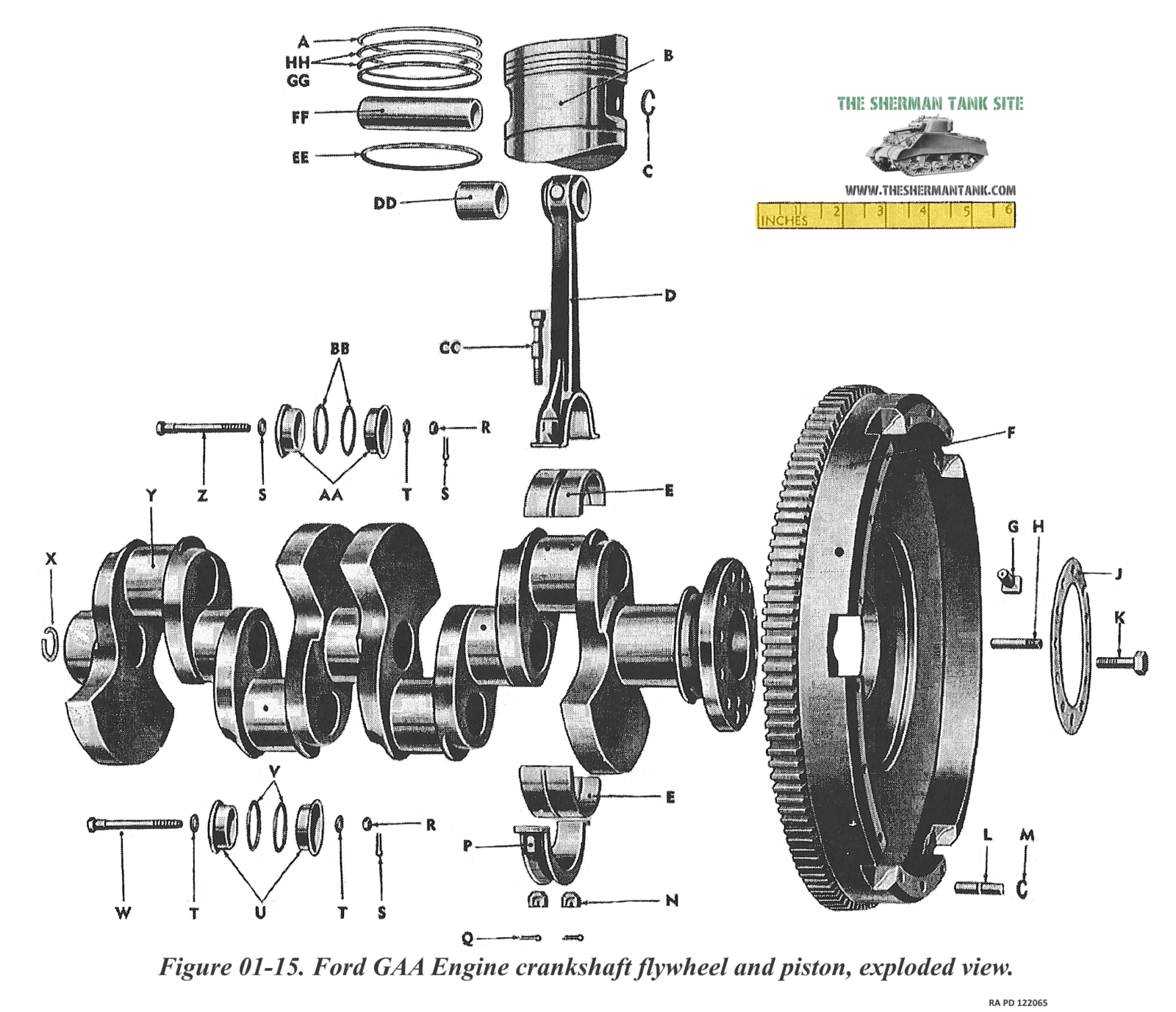

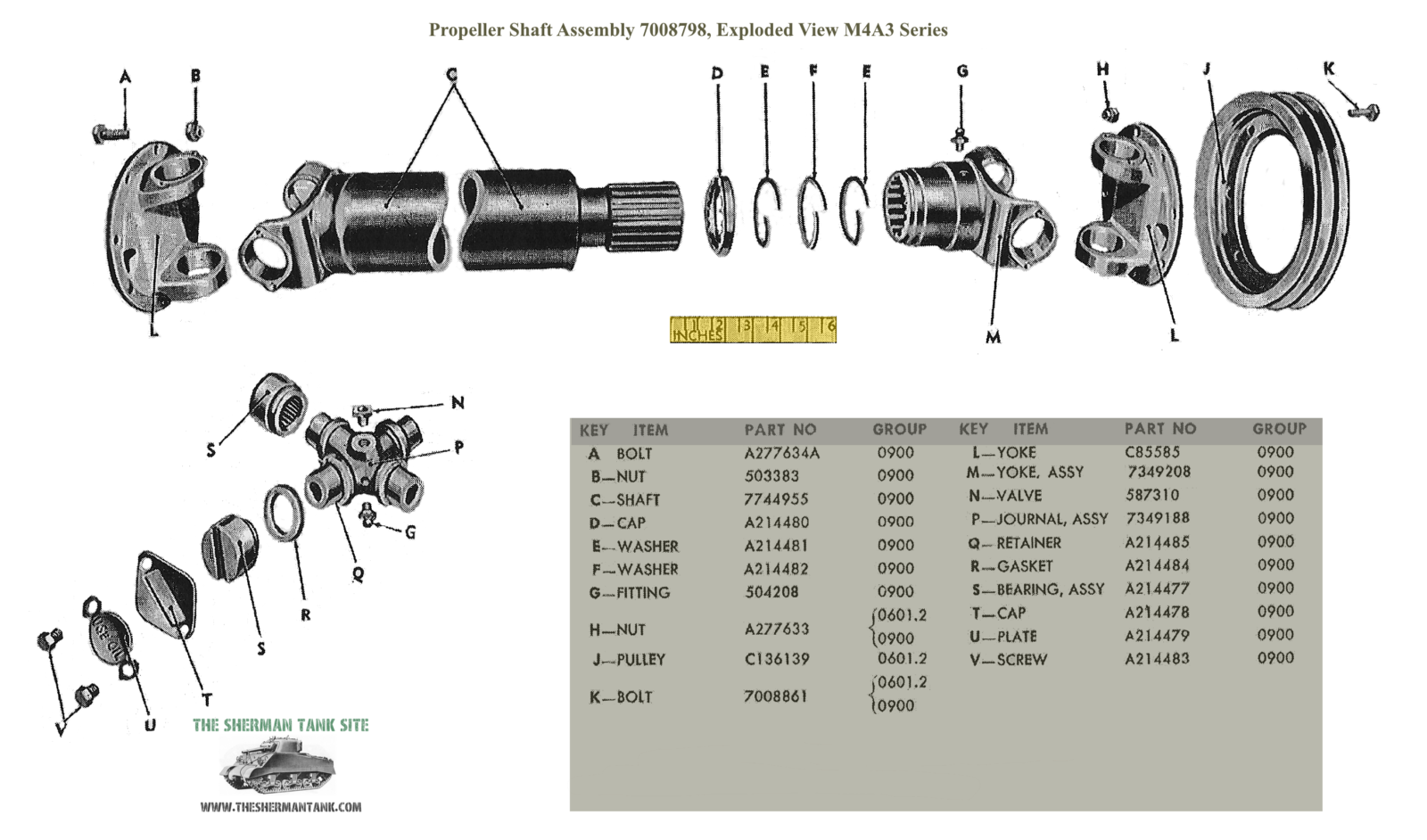

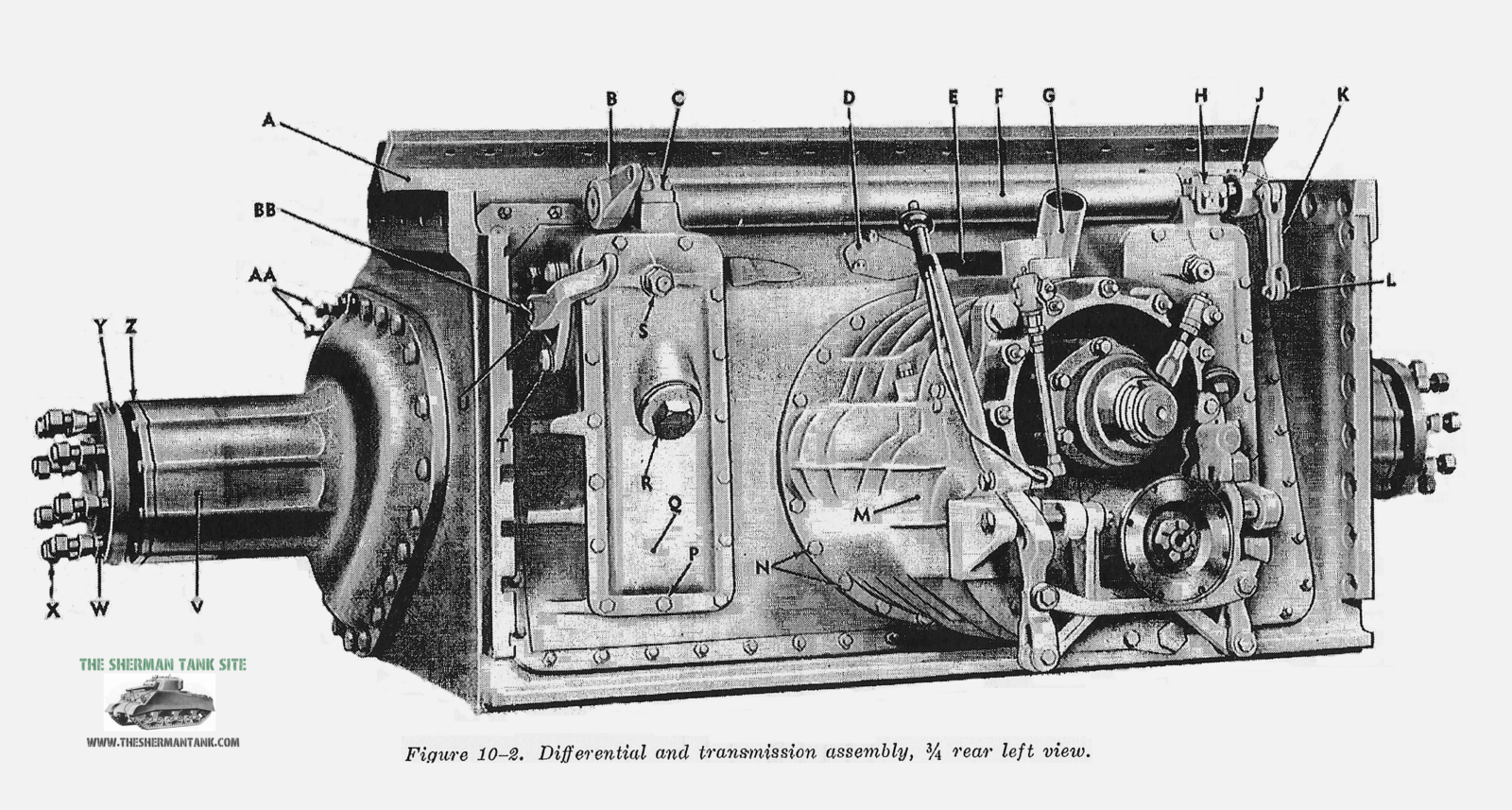

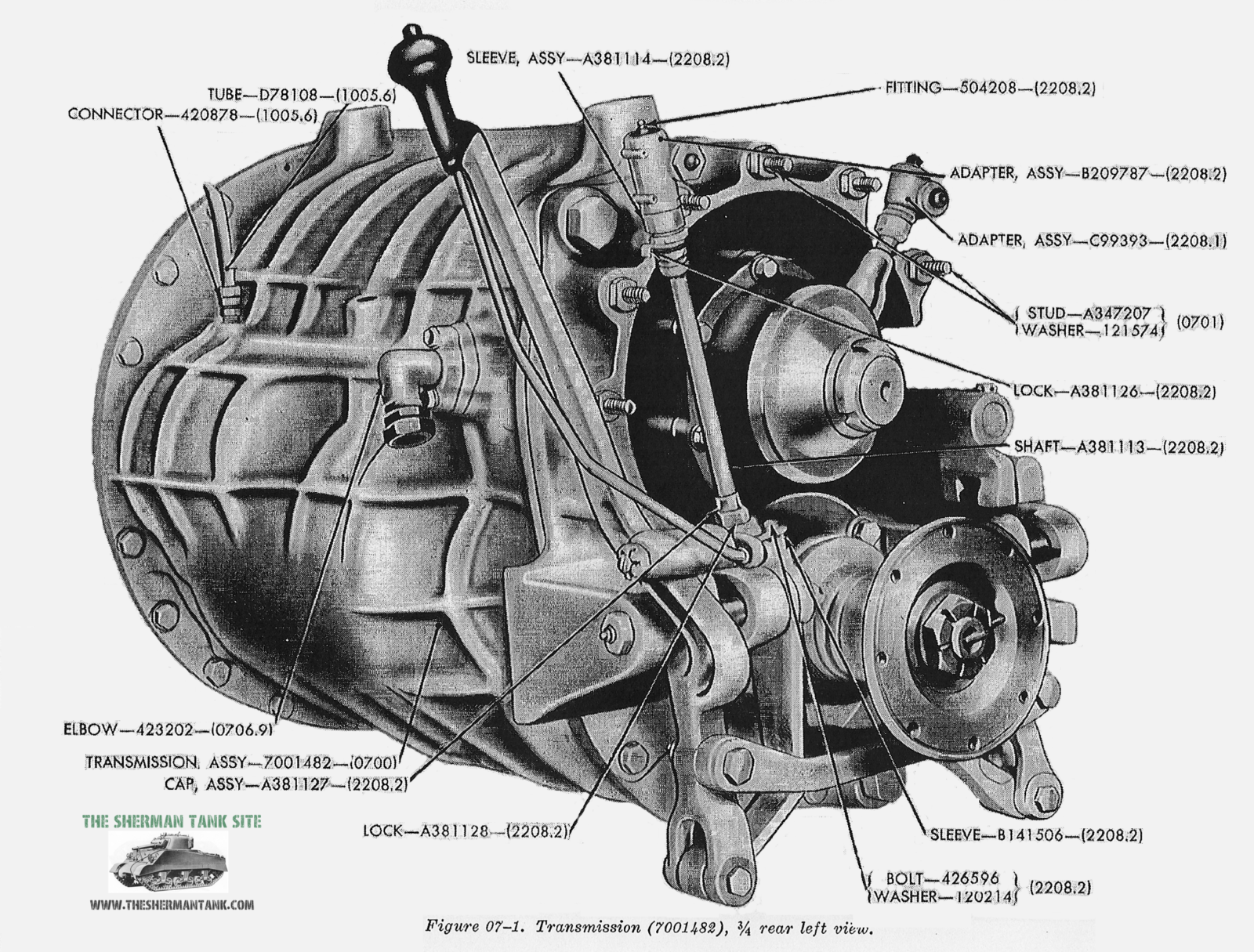

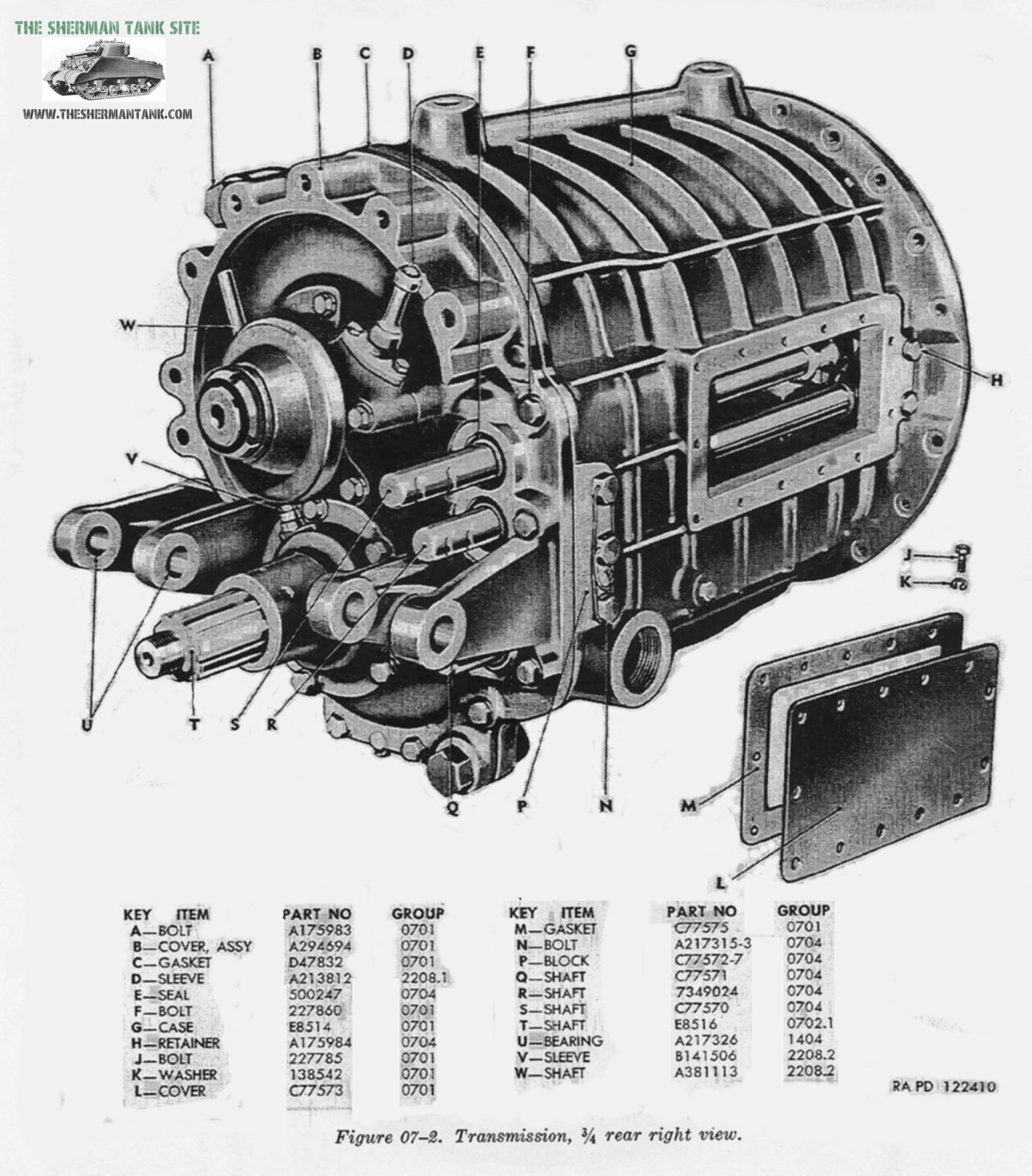

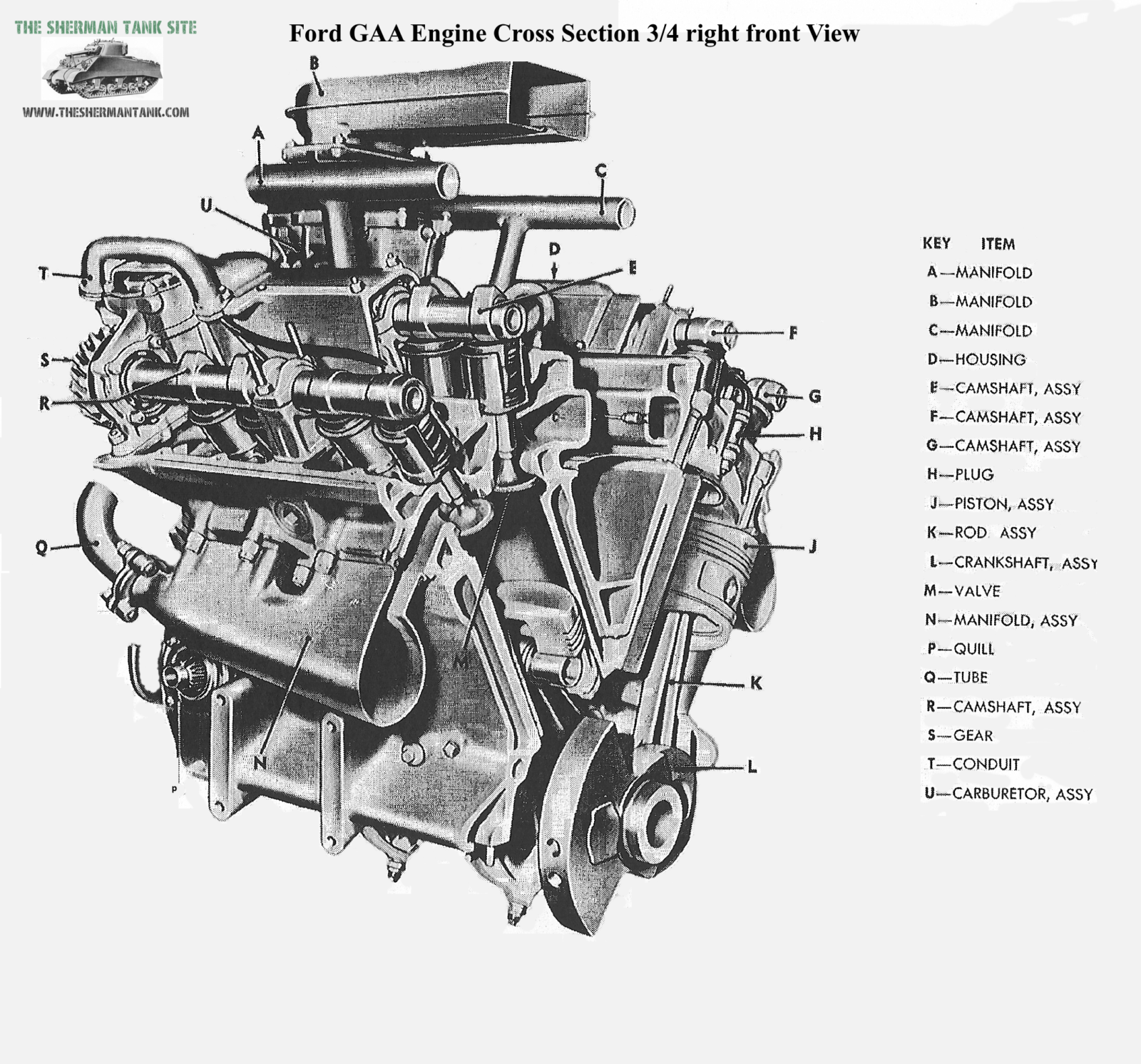

I’ve gotten my hands on a lot of manuals, and they are all great for gathering info on the Sherman, because you can almost always read them. The picture quality varies a huge amount depending on how it was created. There are some very common and easy to find Sherman manuals with terrible pictures. For example the two I have on the M4A3, and the manual on the Ford GAA, both were probably photocopied multiple times, then scanned on a really early scanner.

This means, the pictures at best, are mostly black blobs, and even the text isn’t great. All isn’t lost with these, as the line drawings usually come through ok. In some cases the manuals being sold online are these terrible photo copies printed into a cheap book with no improvements to the quality at all.

Some of these manuals have been scanned in by people with decent scanners, and these though much larger, have much nicer photo quality. Even if the scans are good, the original has to be good as well, and in some cases that’s really mixed. I have several, scanned at very high resolution, making them restorable, to some degree.

I’ve done the most work on the Ford GAA imaged I have, and the tranny. Here is a selection of the ones I’ve done, but not all. Check out the power train and GAA pages for all of them. These are relaxing to do, and I have a ton to work with so keep checking around the site!

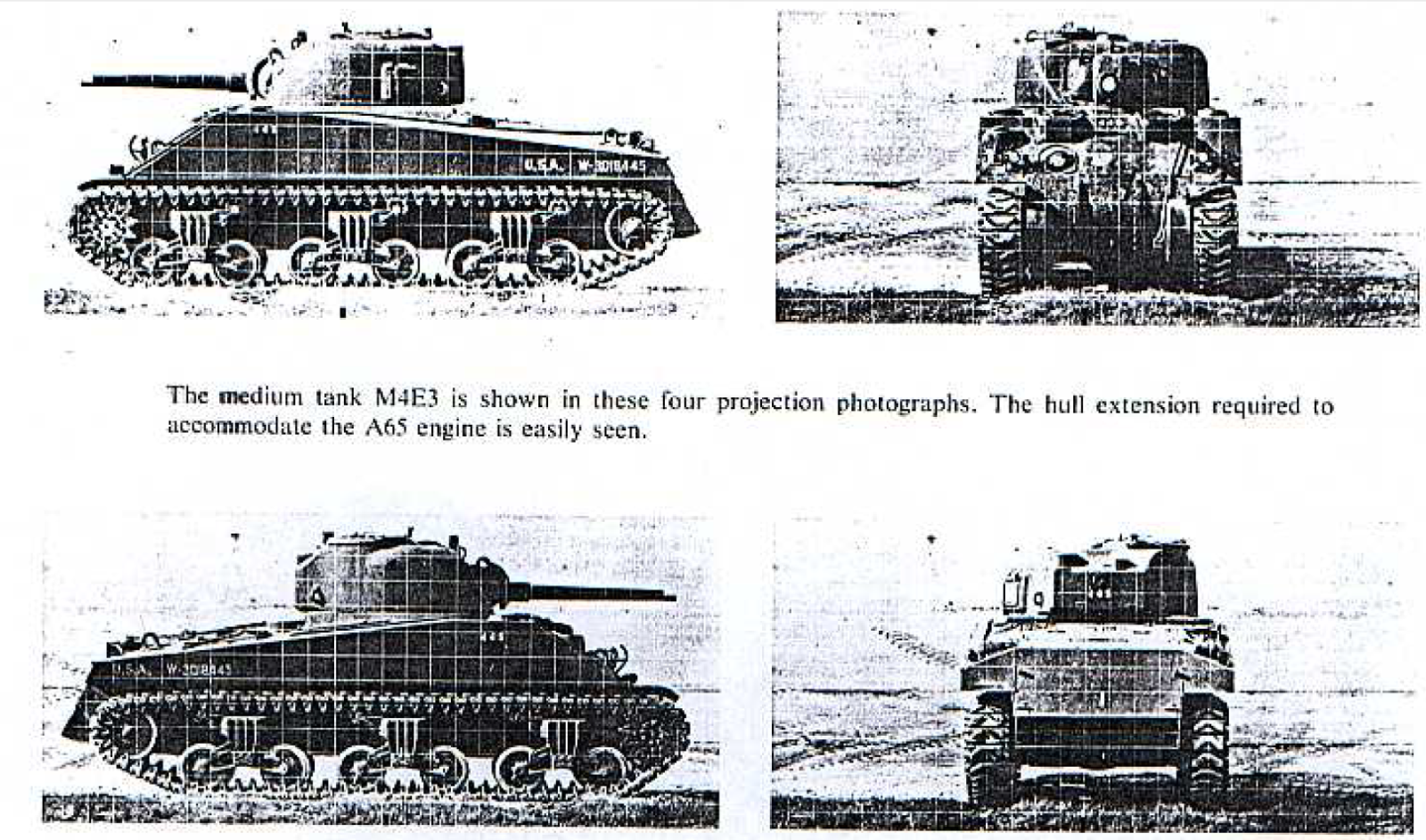

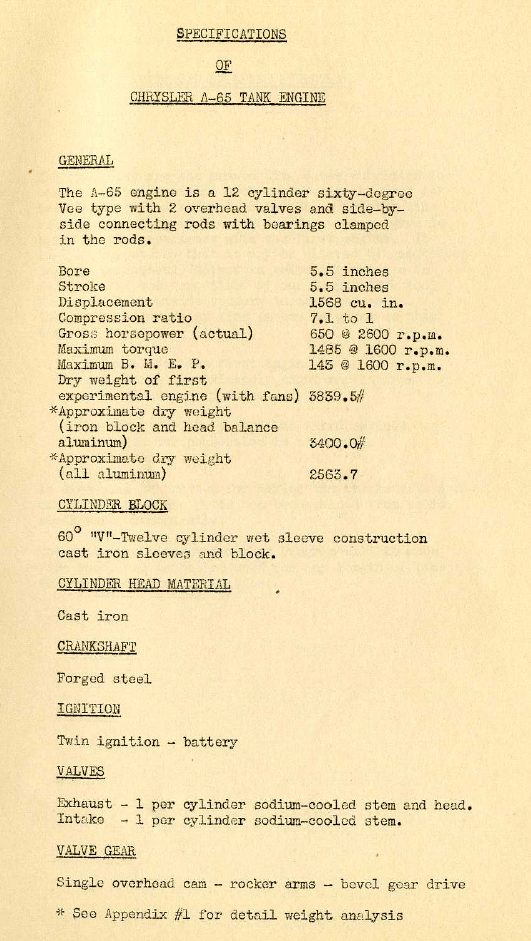

#68 The Chrysler Engine that could have been: The A-65 V12, Chrysler’s home designed tank motor.

The Chrysler Engine that could have been: The A-65 V12, if the war had gone on, there could have been some hotrod Shermans.

Chrysler Corporation had a big impact on the war, and US Tank production. They produced the first, and the model for the others, Tank Arsenal CDA. They also came up with the A-57 multibank tank motor, that powered a significant number of Sherman tanks. They produced this fantastically complicated, but also reliable motor in a very quickly, and even though the US Army and Marine Corps thumbed their noses at it, it was well liked by the British.

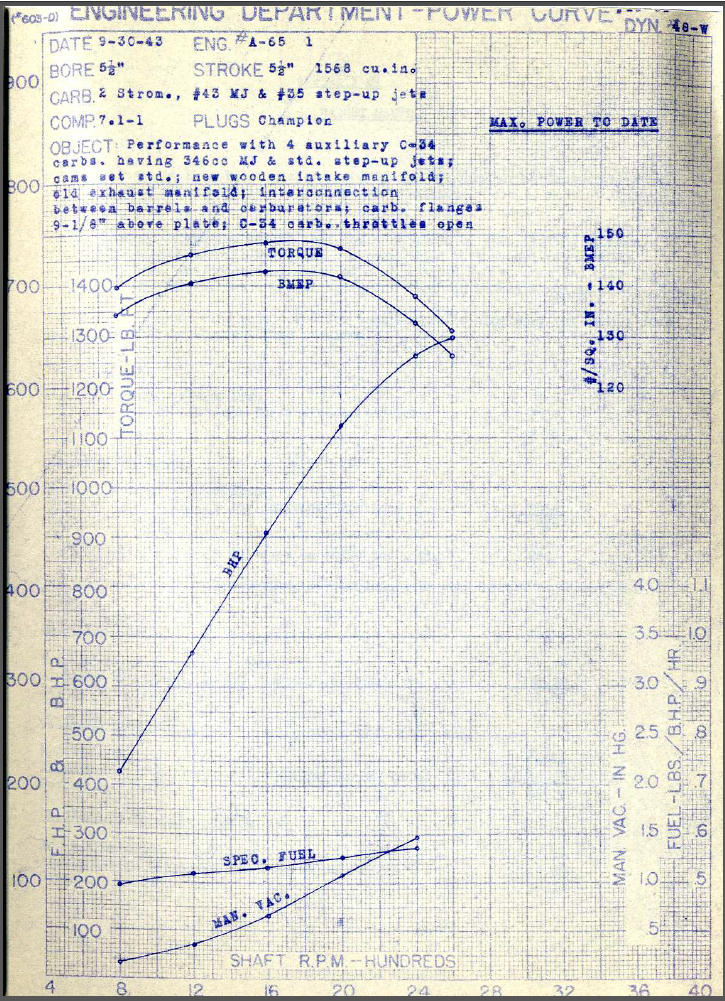

Chrysler on their own dime came up with a water cooled, V12, tank motor, and offered it to the Army. It took them about a year to come up with three trial motors. These 1568 cubic motors started out at 650 horsepower at 2600 RPM and 1485 pounds of torque at 1600 RPM on the test stand. They came in around 3840 pounds, but there was a proposed all aluminum version that have dropped nearly 1000 pounds. Designing and producing the prototypes, cost a grand total of 358,000 bucks, that’s over 5 million in today’s dollars. During the dyno testing period, they had a few problems with the fan drives, but these were solved with improved oiling and rolling bearings, and these seemed to have solved the problems.

They used an M4A4 as a test vehicle, and had to stretch it another 9 and 1/2 inches to fit the new motor. Installed and ready to roll the thing came in at 69,170 ponds, and a stock M4A4 came in at 69,640 pounds! Installed, the early versions had 549 horsepower, but they upped the compression ratio and got it to 580, and it was improved even more with some carburetion changes. They made the compression change by swapping and a cam change during the in vehicle testing phase. Further testing led to the intake and carb changes. All the while the motor was being swapped in and out, and driving tests done.

The automotive tests were very successful, and that was using the stock powertrain of the Sherman, though with so much power, they decided a gear change would help. By swapping the original 3:53:1 gears for 3:05:1 gears, they A65 was still able to beat an M4A43 in a drag race! The engine was so promising, it’s an interesting mystery why the Army never developed it further. Much like the GAA, there was much more performance potential in this motor, and the Army never took it any further.

I suspect what ultimately killed this motor, was the same thing that killed the GAA, the Army was looking at air cooled motors for the future, because you can save a lot of weight, if there is not liquid cooling system needed.

Special thanks goes out to Chris R, one of our readers and a source contributor, sent me a nice little history on the motor. Thanks again Chris, sorry it took so long!!

Sources: Sherman, by Hunnicutt, and 1943 A-65 Tank Engine History

News Post #10: Sherman Tank Site News!

Sherman Tank Site News, April of 2017 edition: Data Part II, Data Strikes again.

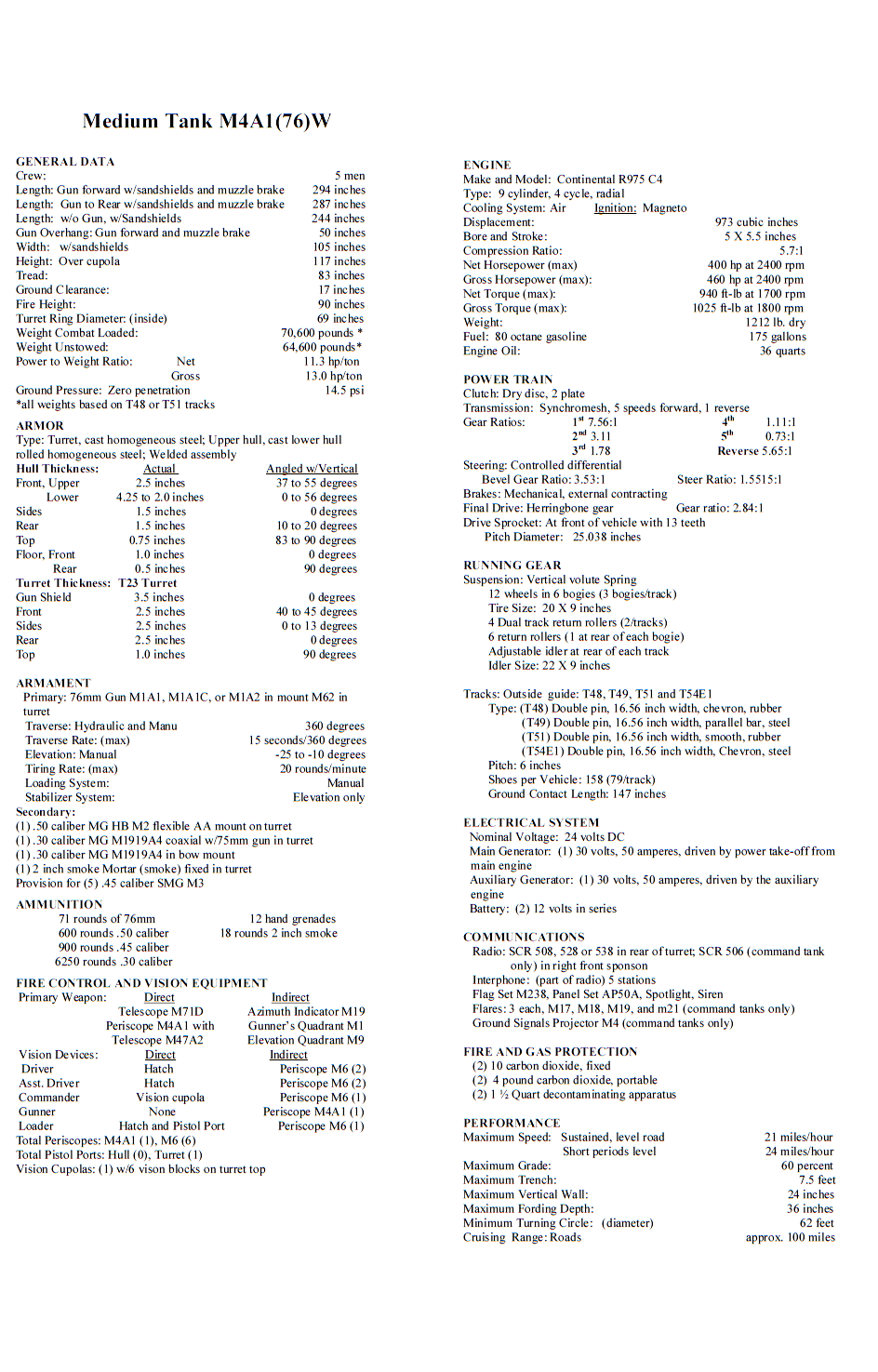

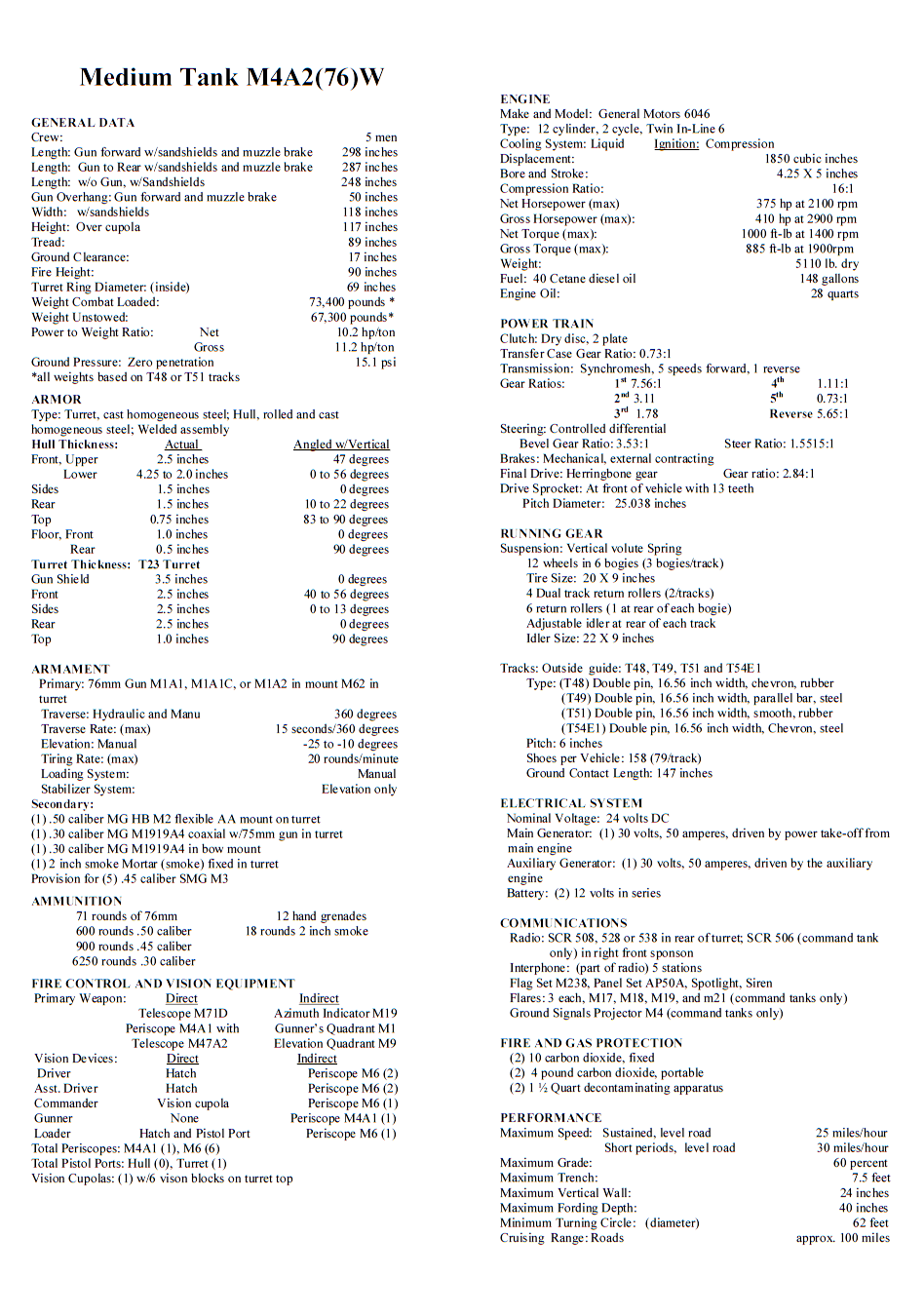

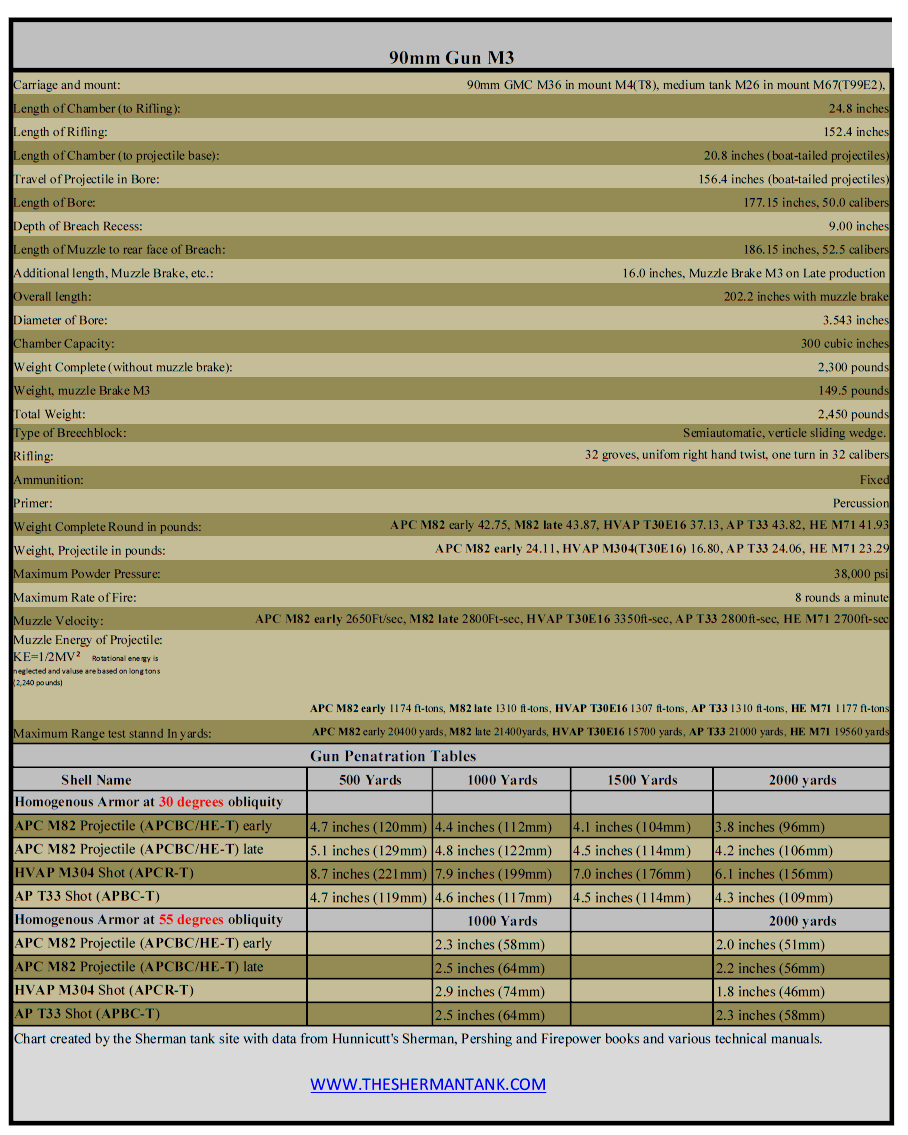

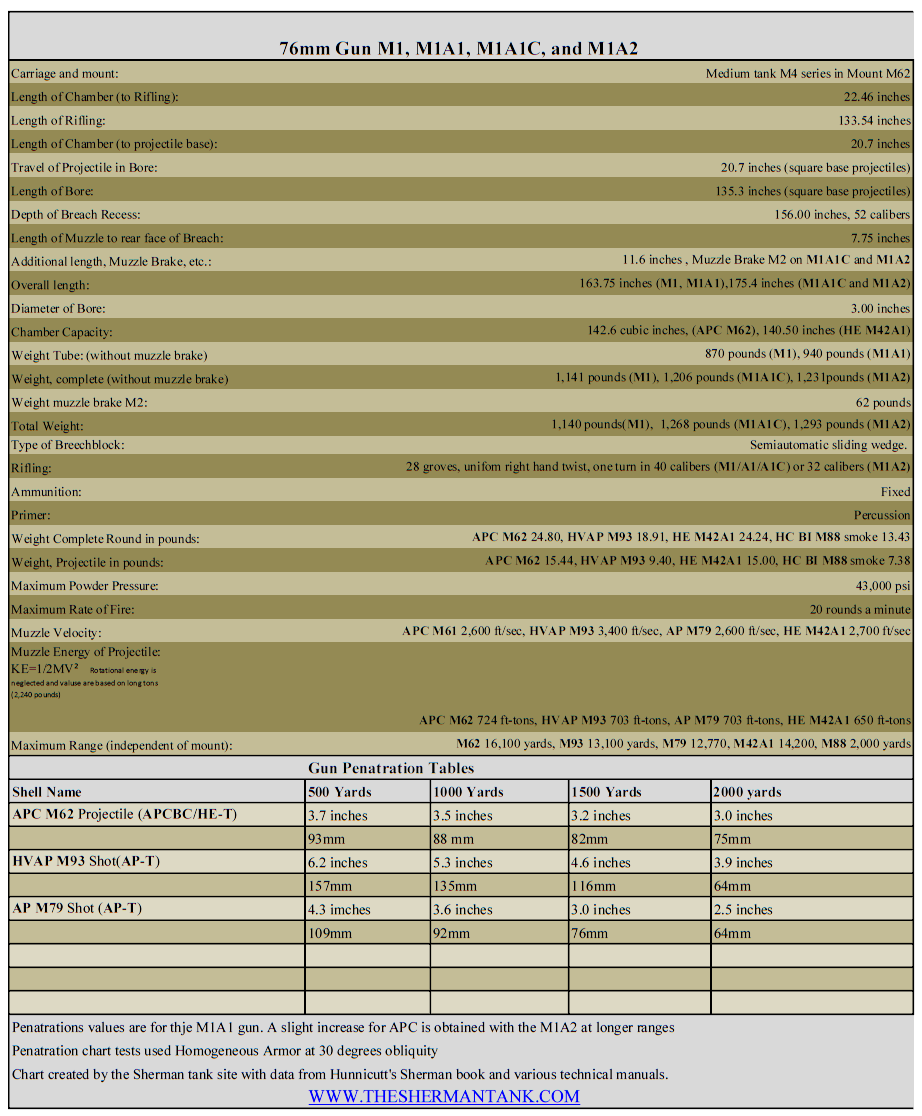

The Sherman data sheets have been a very popular addition to the site, so I decided to gun and engine data sheets as well. One motor Data Sheet is done, and the others are in the works. There are all kinds of new images and info in the various pages on the Shermans guns.

We also have a new layout to the website, instead of a lot of hard to find posts with an Index that was hard to find things in, we now have set pages, of the main menu.

As you can see from this handy image, we have a page for the Shermans suspension and Track systems. We have a Sherman Gun Data page. We also have a motor data page, but right now we only have the Ford GAA in it. Now we also have pages for each tank model and a main page to find them. There have also been minor image additions to many posts, and a few pages have received minor updates.

The Crew and their Stations post got a massive update as well.

We also recently reviewed an inside the Hatch of the M4A1 tank.

Coming soon will be the Sherman Transmission, differential and final drive data sheet. I will also be filling out the individual Sherman model pages over the next few days. There is only so much I can do in a day!

Thanks for being interested in the site for all the guys who have commented and sent me interesting info. More great information on the Sherman tank is on the way.

Sherman Tank Site, News Post 9: DATA, DATA everywhere!

News Post 9: New Years News

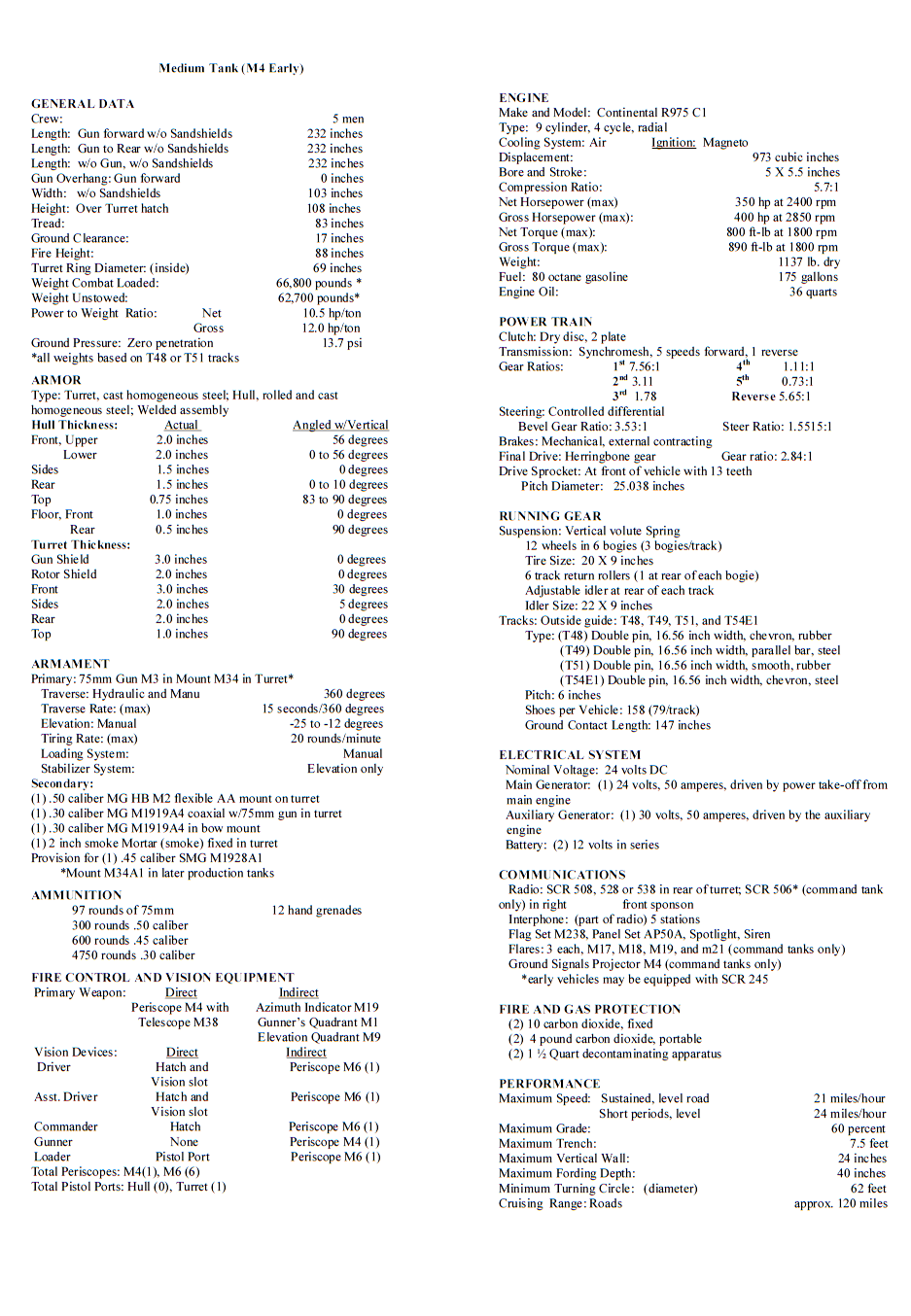

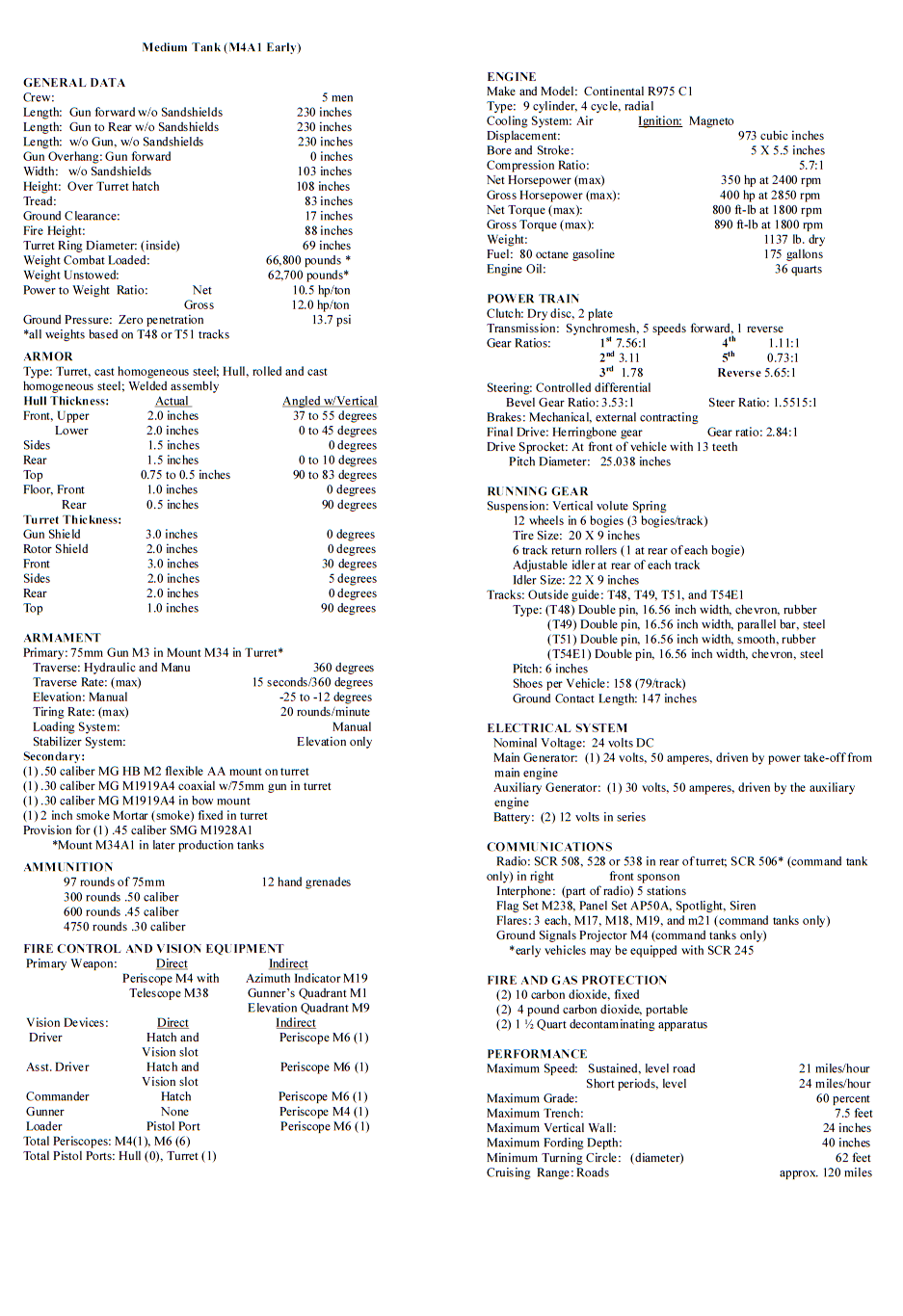

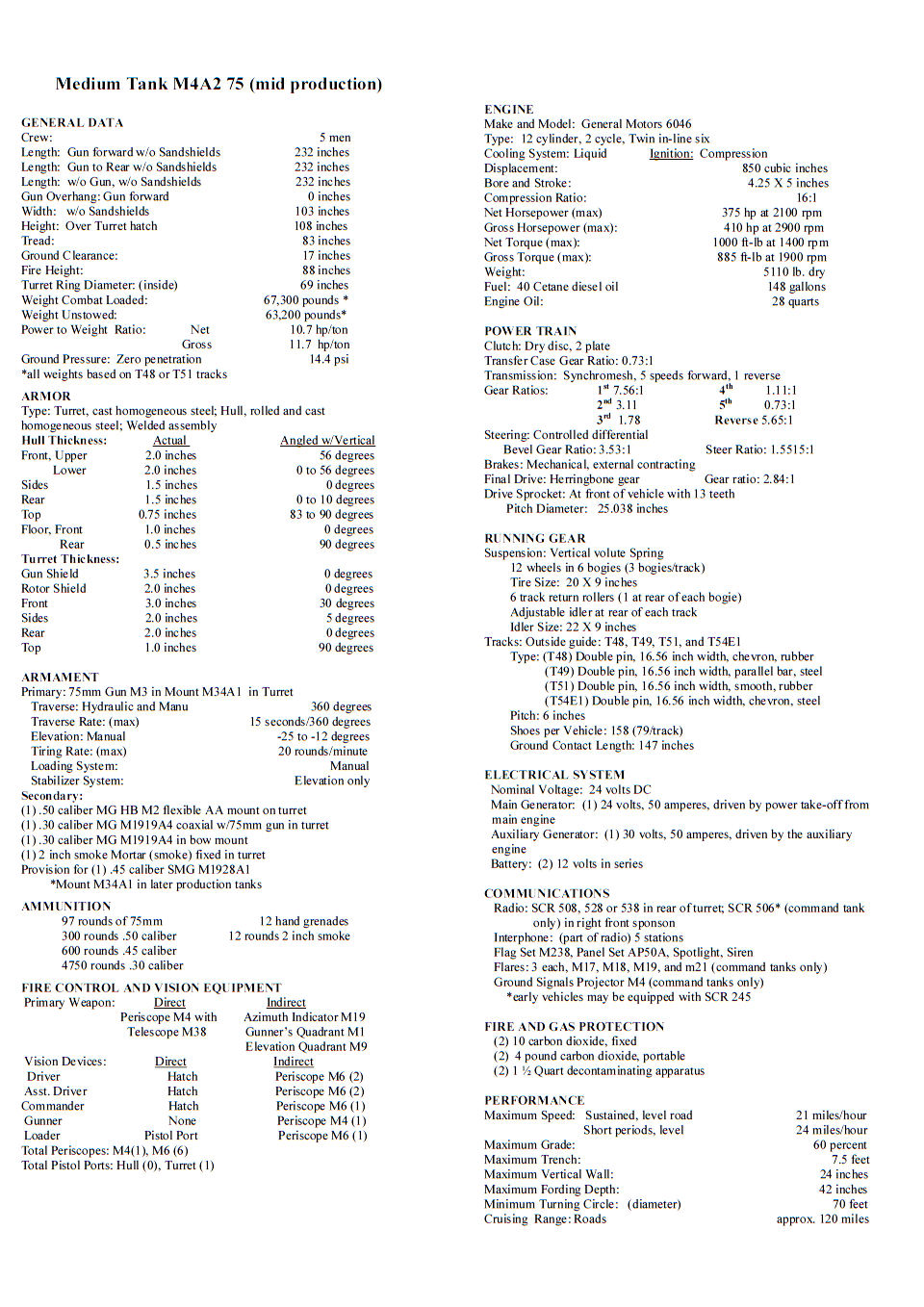

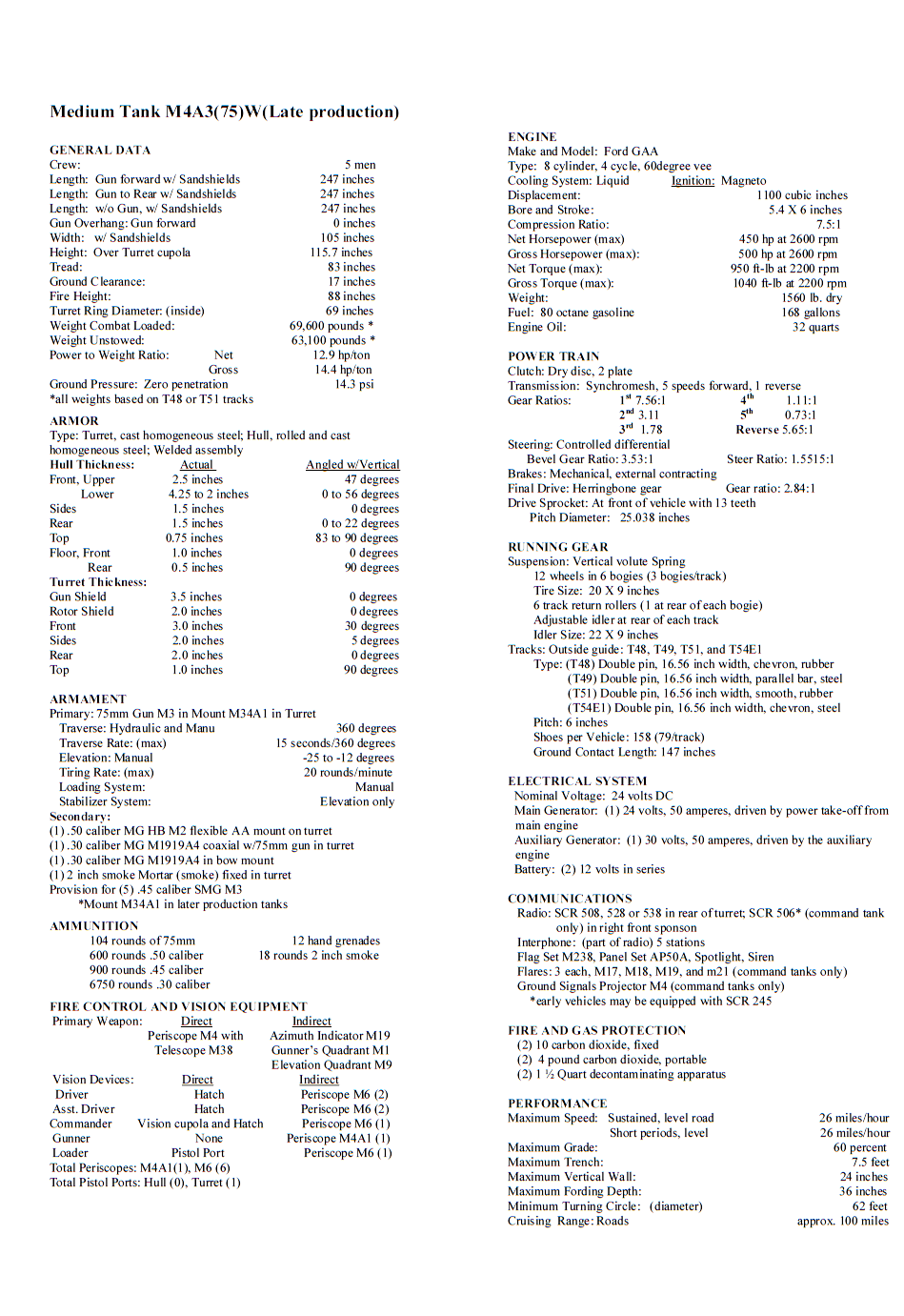

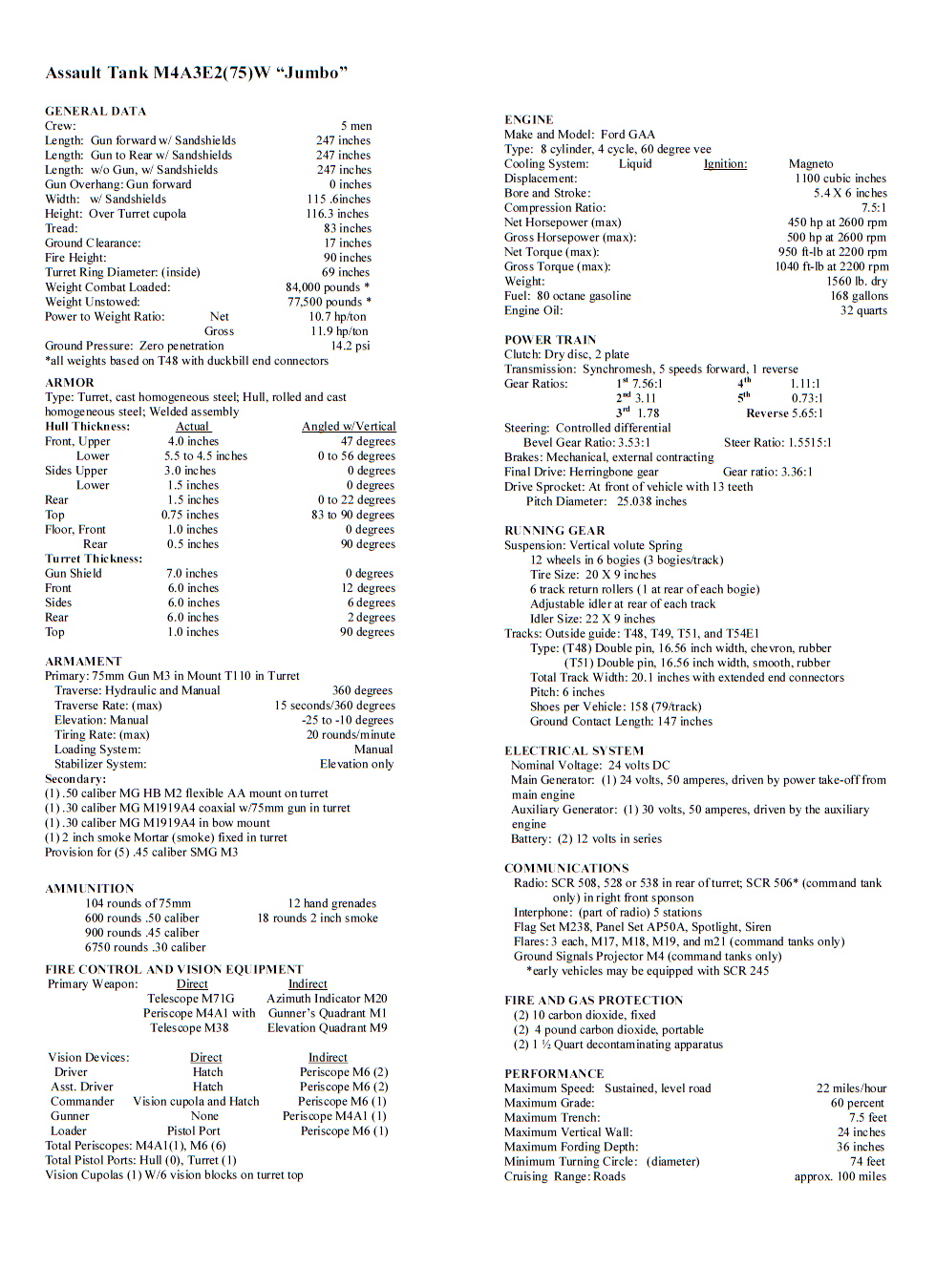

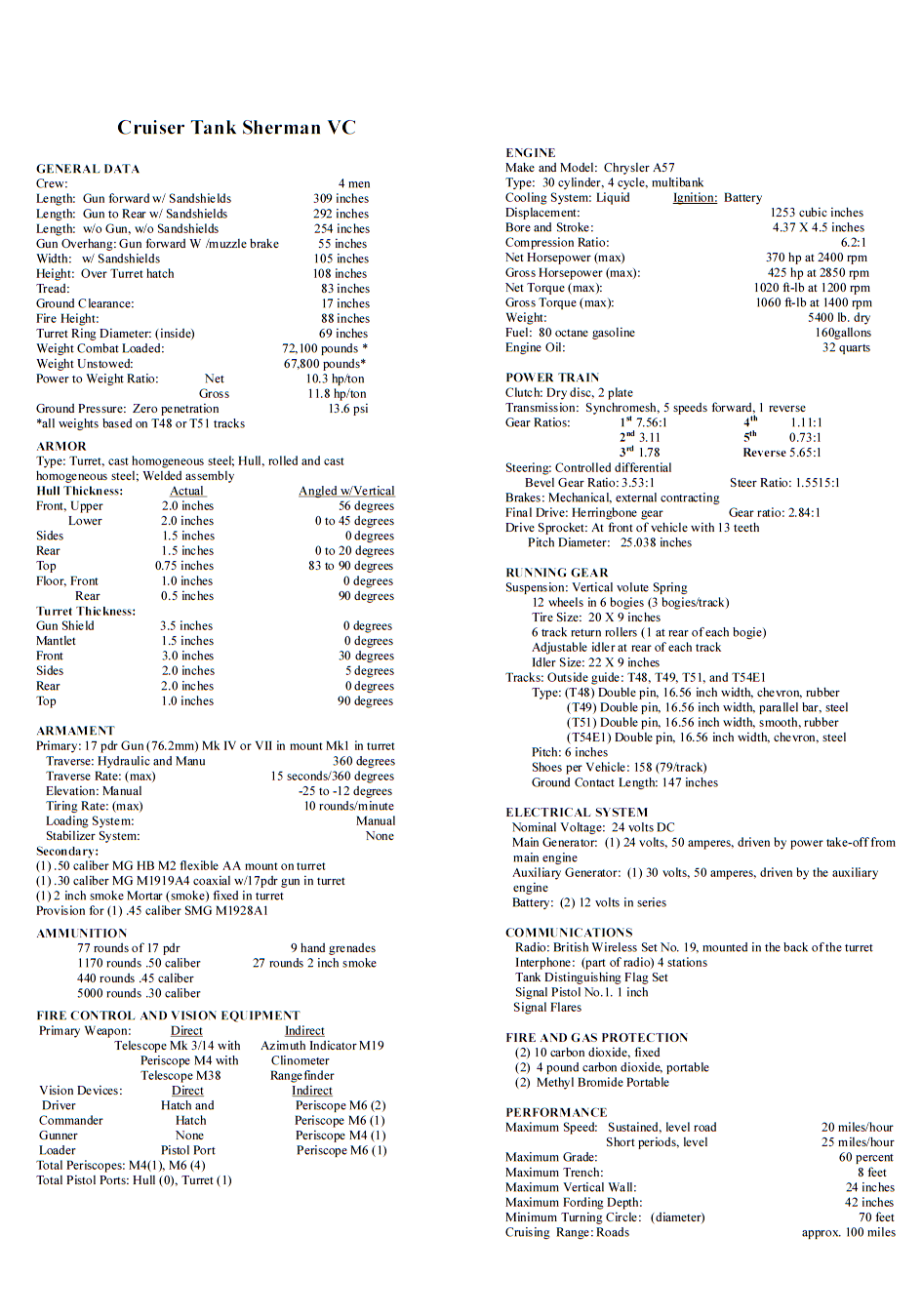

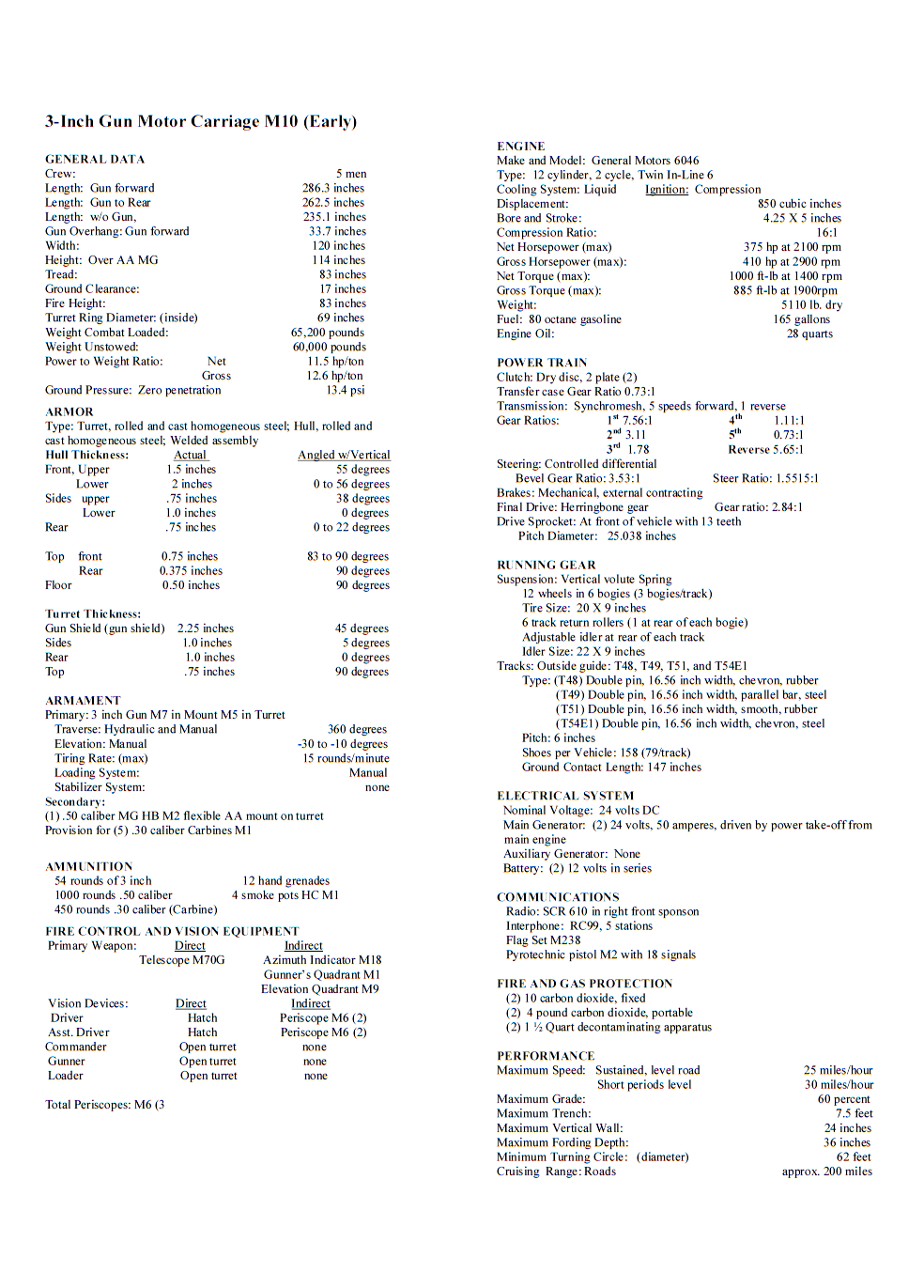

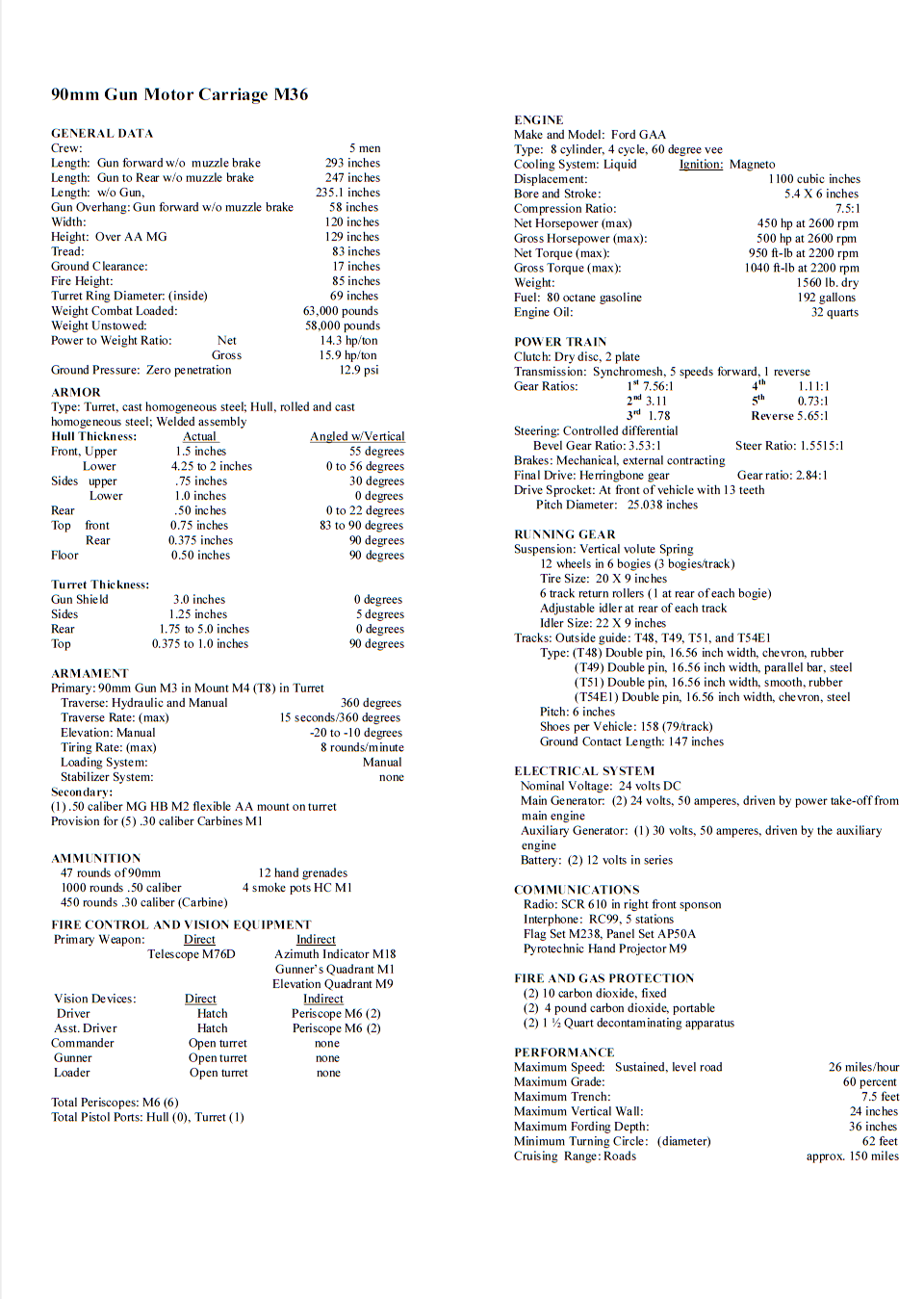

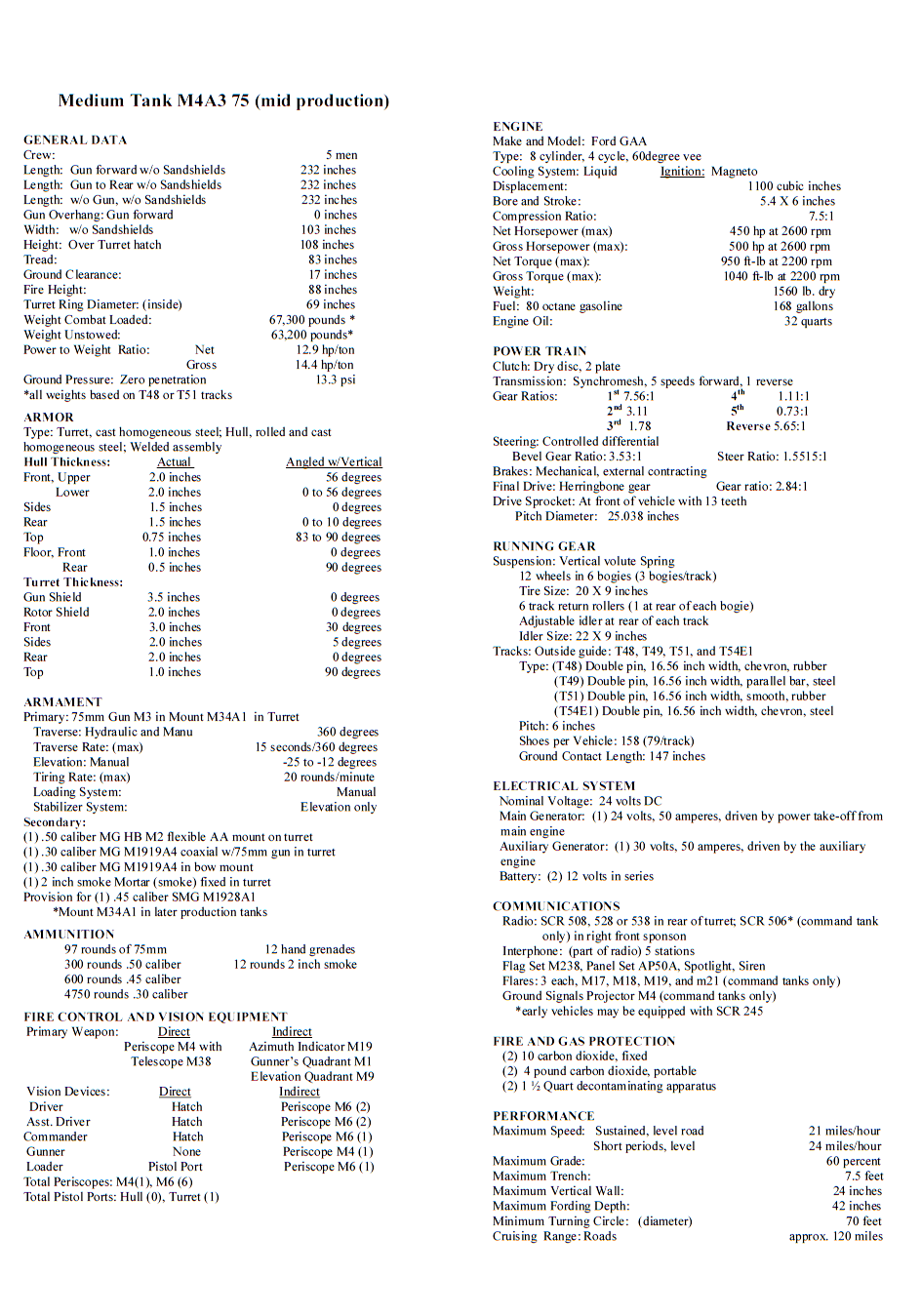

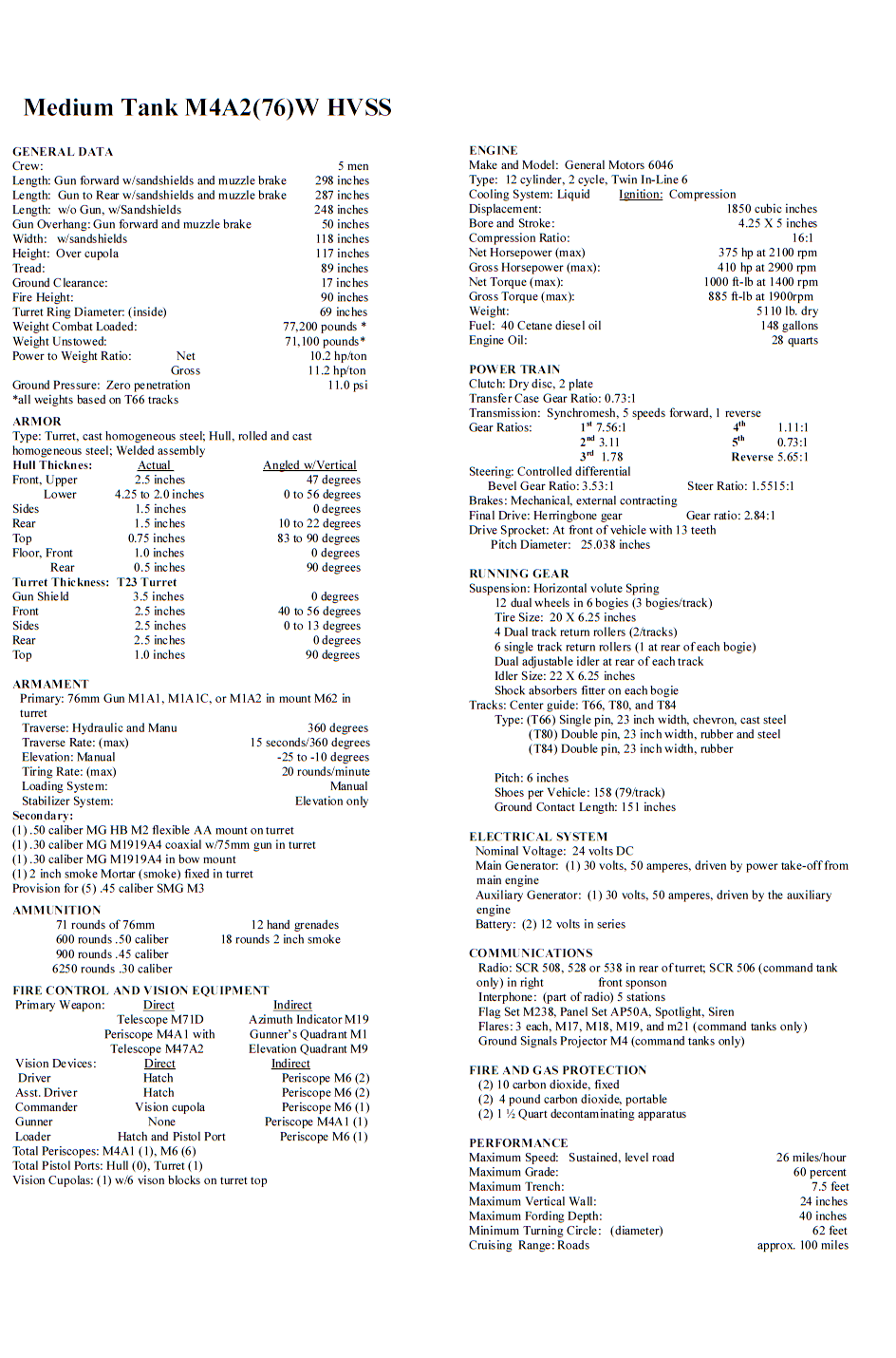

I decided I needed more hard numbers, the kind of data that makes non tank nerds eyes roll up in their heads, stuff like how many spare periscopes were issued with an early war M4A1! One of the best way to do this is through tank Data sheets, as found in the back of many books on tanks. I used Hunnicutt’s Sherman book for some, but others I’ve made using the Hunnicutt ones as a template and then using data from the Technical Manual for the tank.

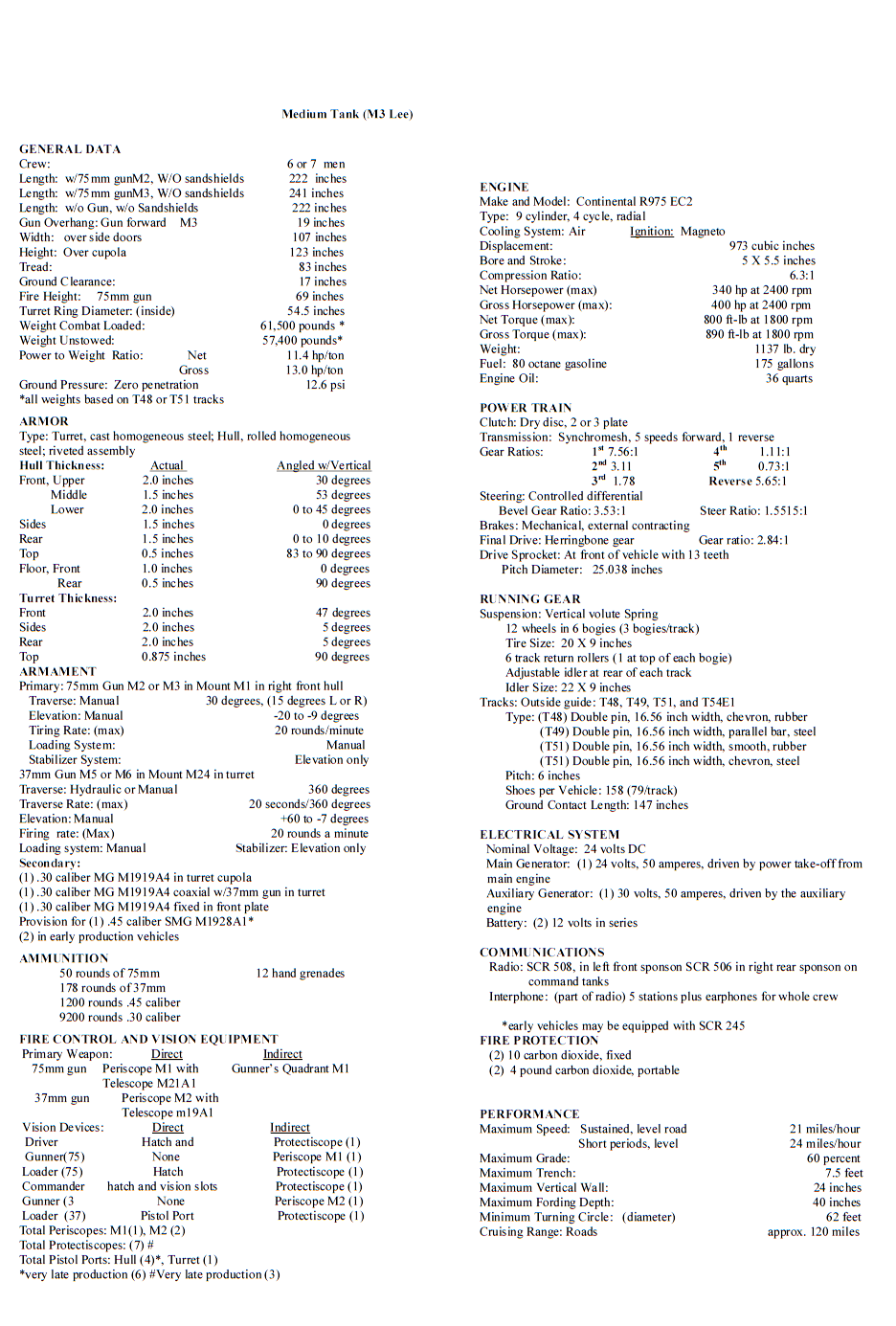

We had four, now have spec sheets for 15 different models of Sherman, and 3 Lees! You can find them all on this page. Shermom Model specification sheets.

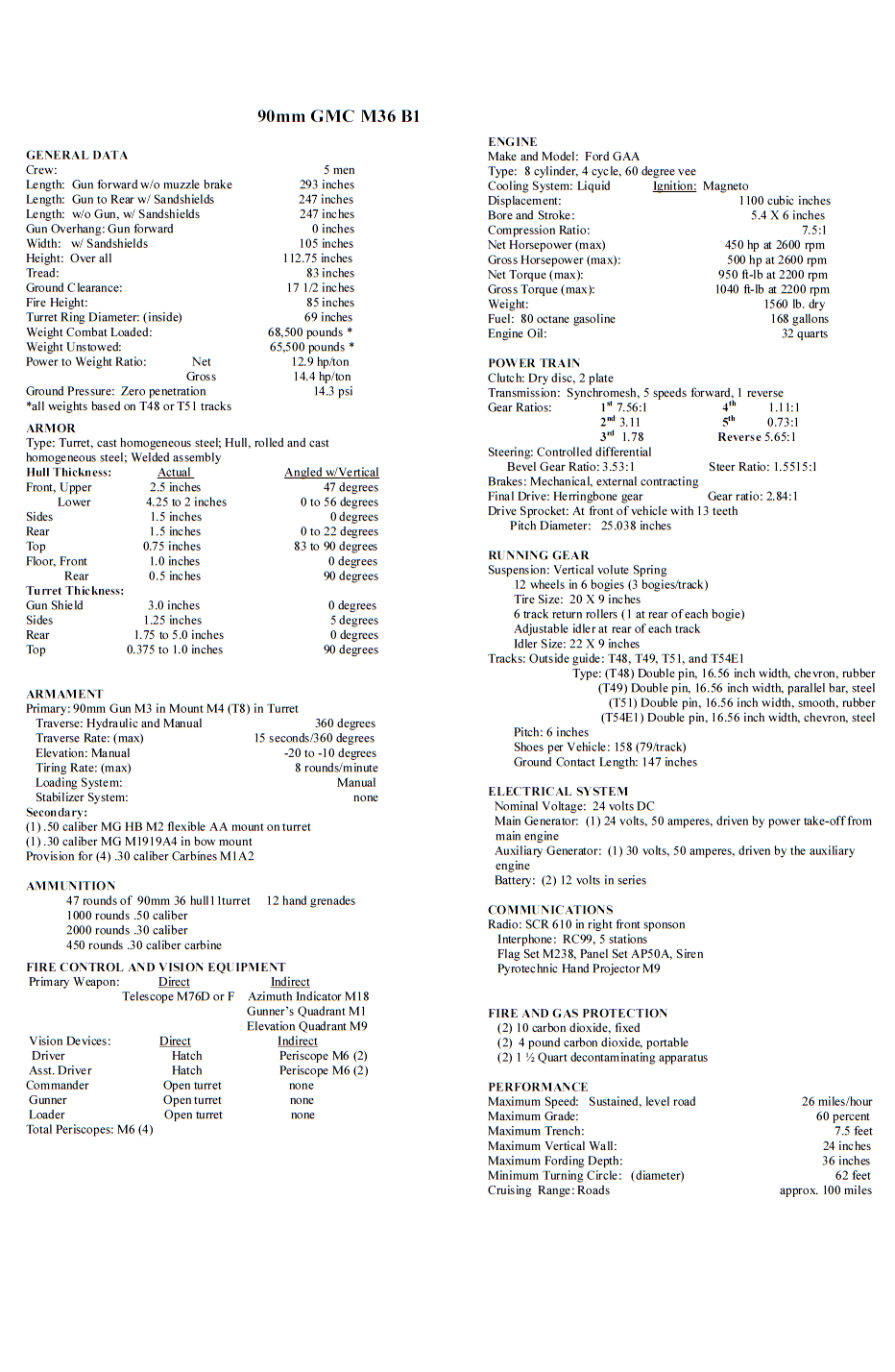

90mm GMC M36B1 Spec Sheet PDF

That’s not all though, I decided the gun Data sheets in Hunnicut were really interesting, so I started replicating those, but with an improved format, and slightly more data. These gun Data Sheets can be found here, Main Guns: THings that go BOOM! All the guns the Sherman tank used are covered, and more are coming.

m1-M1A1-M1A2 guns 76.2 Sherman tanks

In the works are Data Sheets for each Sherman tank motor, and several experimental models. These Data sheets will have much more detailed info on the motor, and will include interesting images from the manuals for the motors.

Also in the works as dedicated pages for these data sheets, the beta test of the gun version is up and can be found here. Next up will be ones for each tank model and then motor.

Also note the latest post on the Ram tank, The Ram: The Shermans awkward Canadian Cousin. This post covers the Canadian and British attempt to come up with a better Sherman before the Sherman design and prototype was done. I’ve been sent some very interesting documents, some are included in the post.

Thanks for reading and stay tuned for more Sherman information!

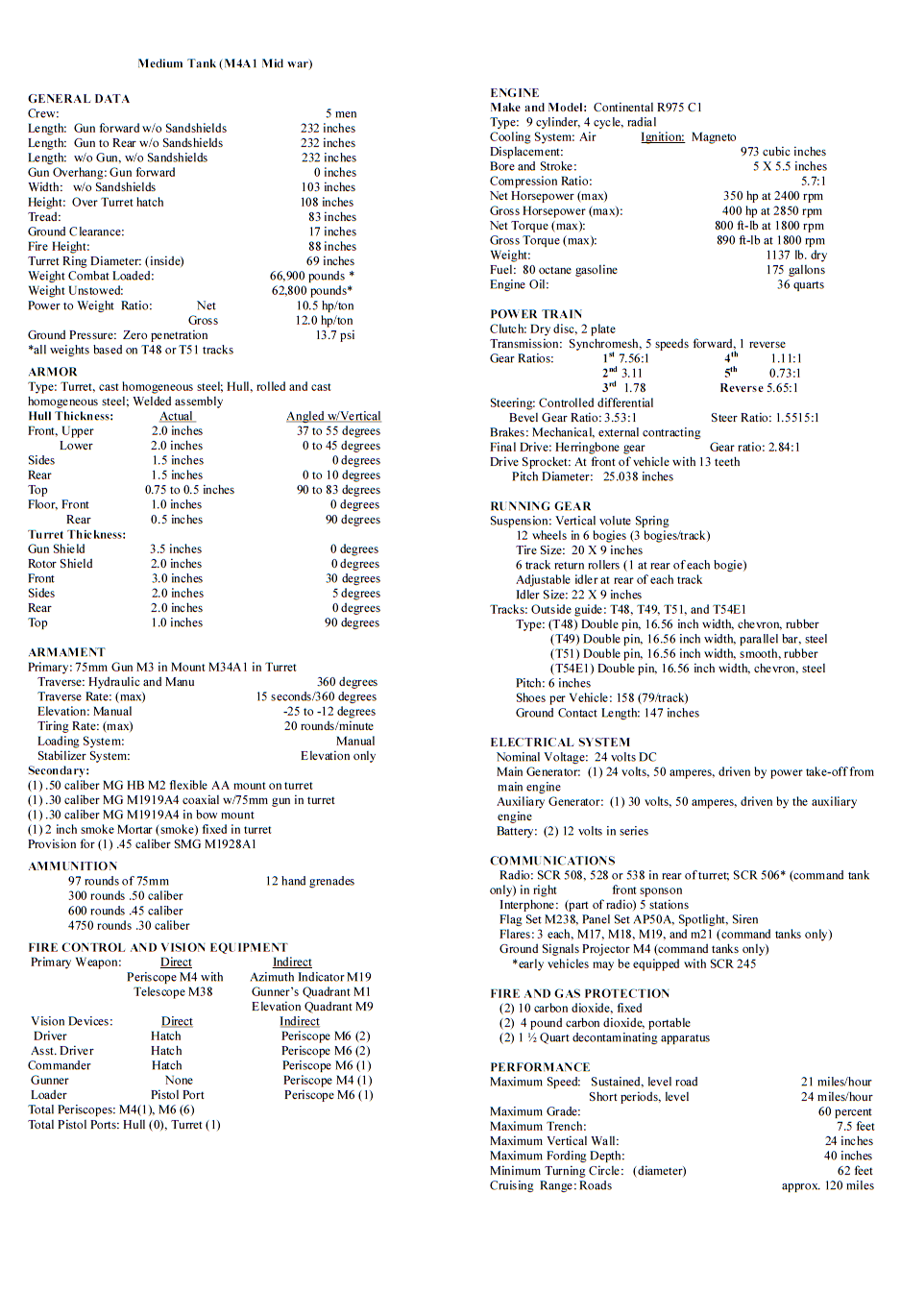

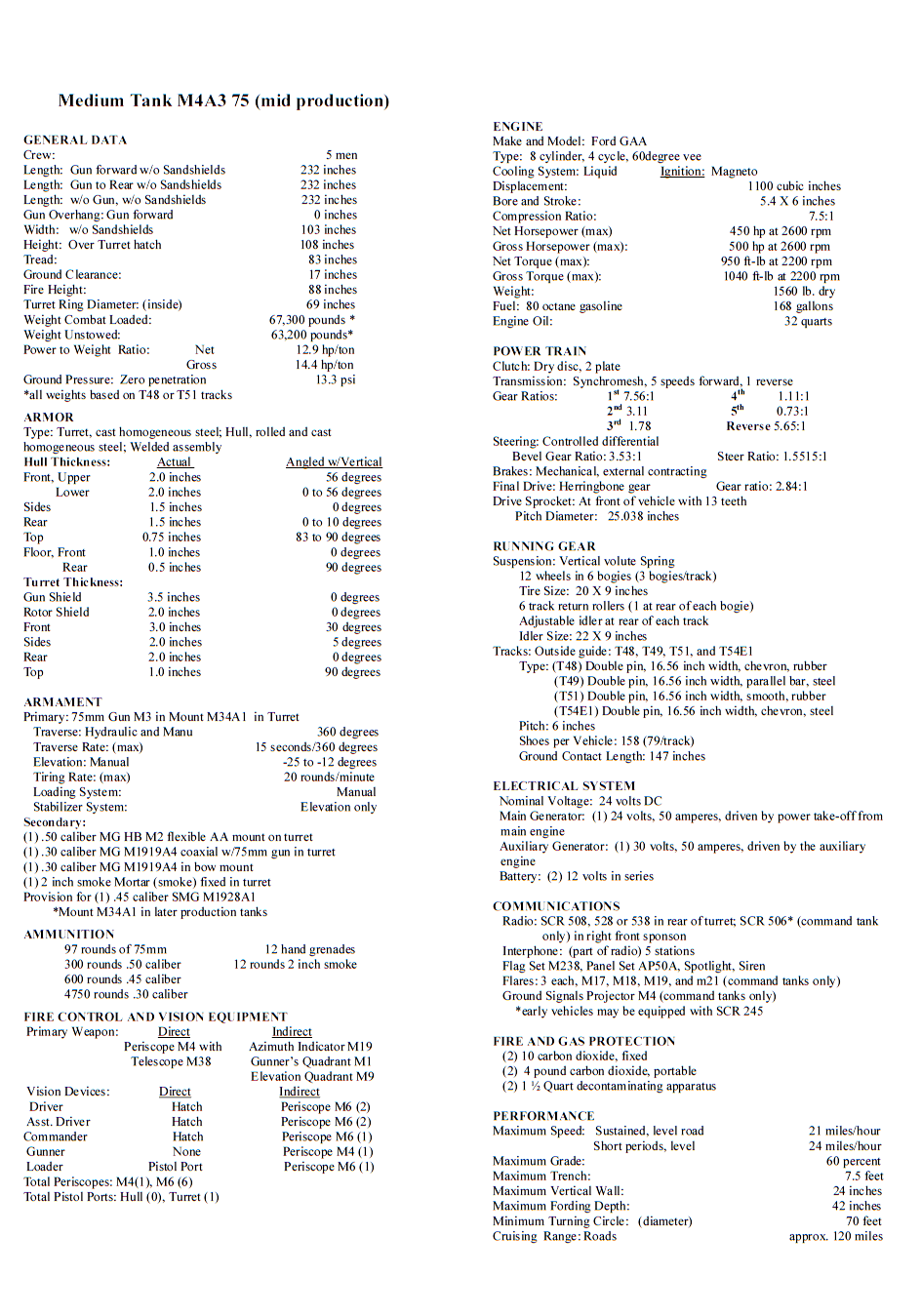

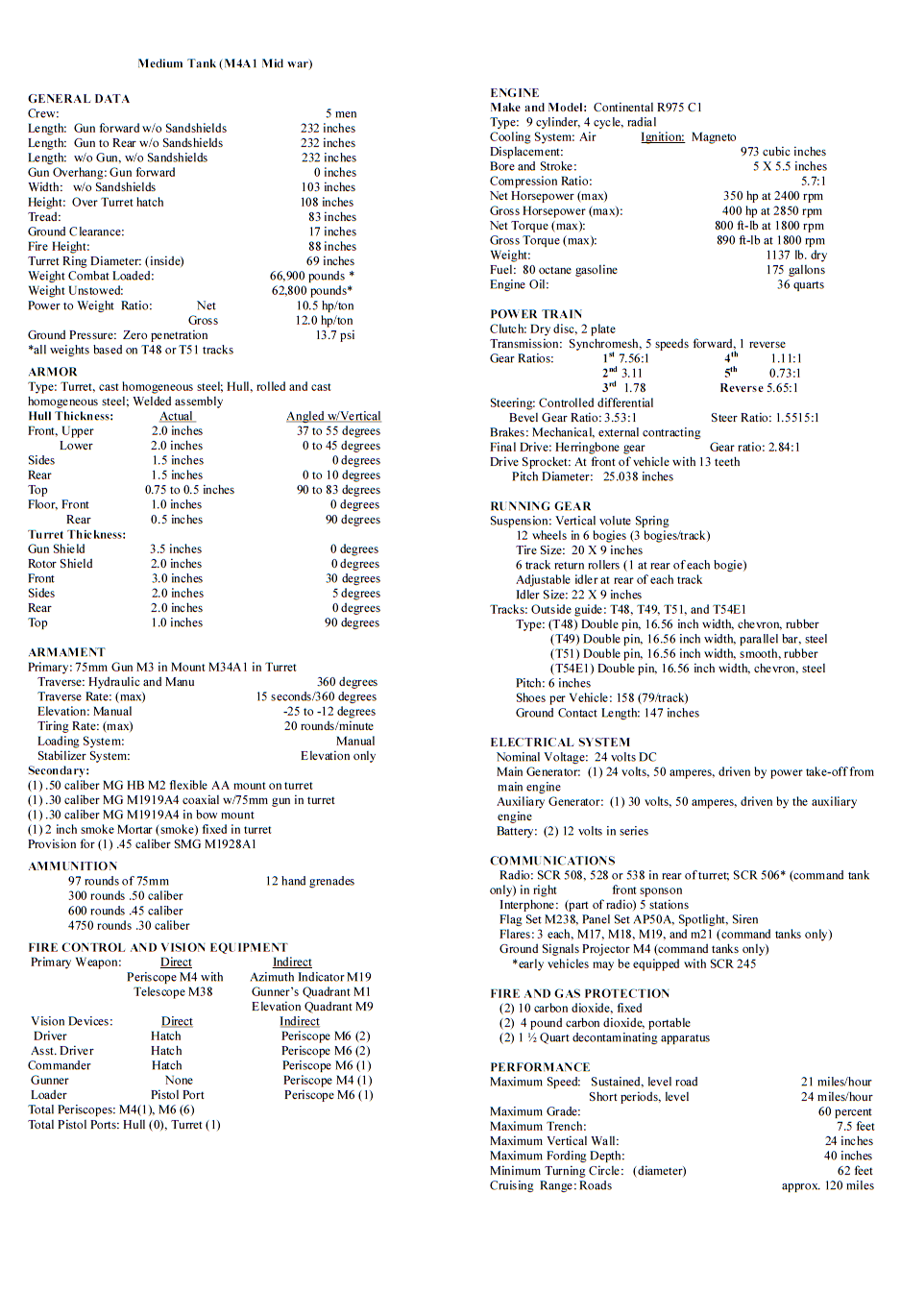

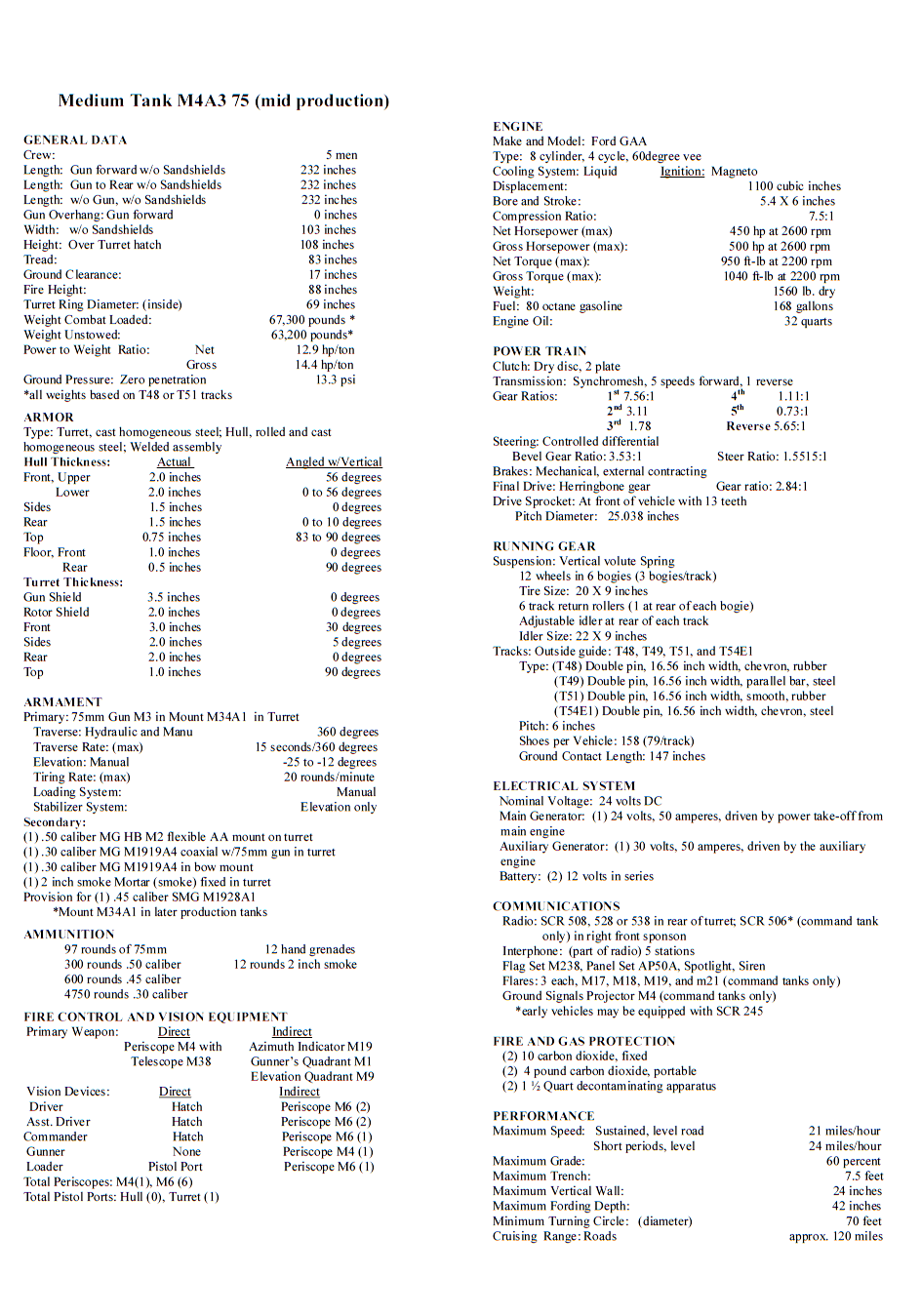

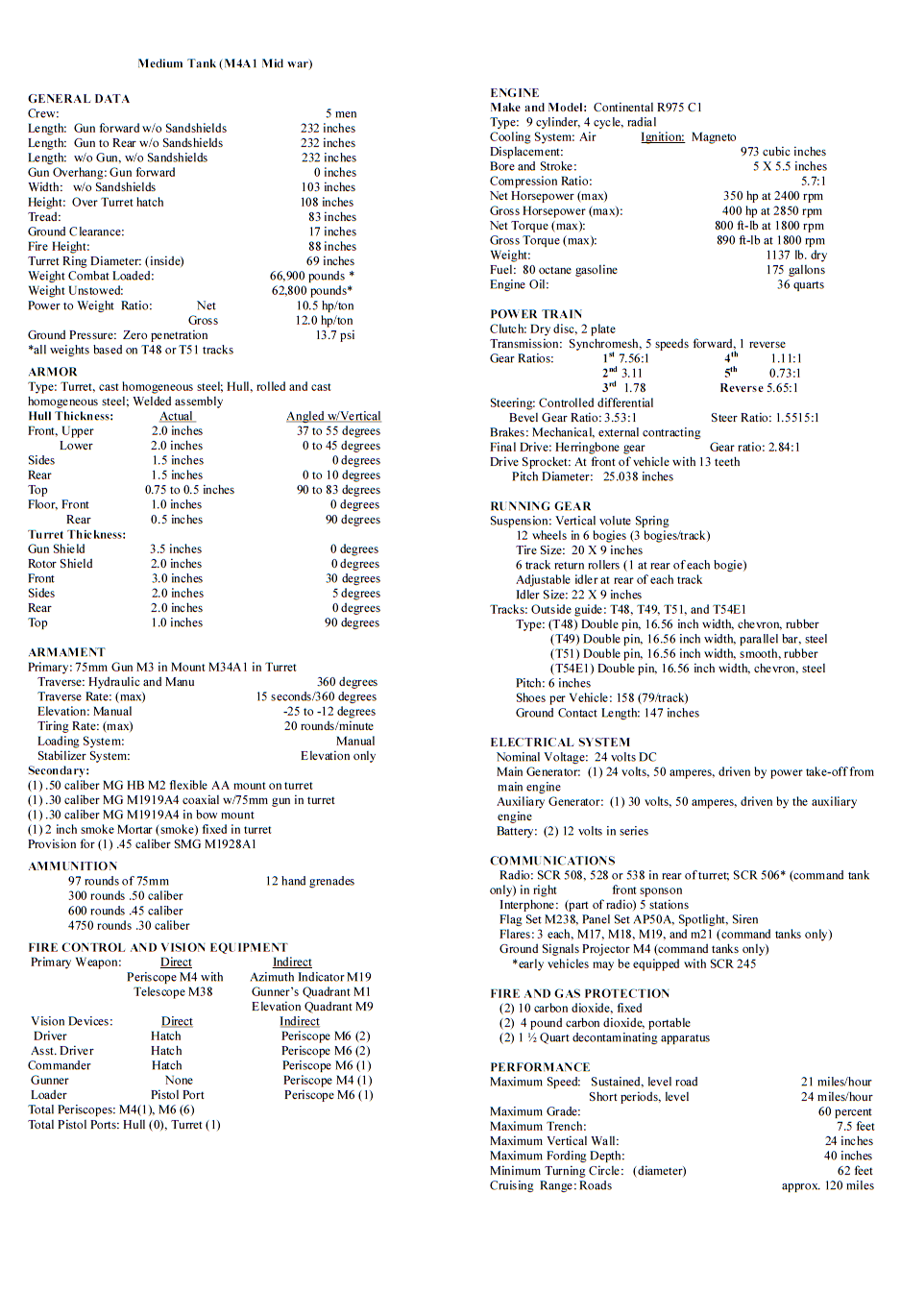

#30 Sherman Model Specifications: Data, and Lots of It.

Sherman Model Specification Sheets: Detailed Data Sheets For Each Model.

These were a pain in the rear to make, the ones in the back of my copy of Hunnicutt are very bad, so I have reproduced some in Word, and then print them out as PDFs, then take a screen shot of the PDF for this post. I have now hosted all the PDF files, if you want something with copy and pasteable text. I’ve got a system not for these and it’s semi easy to do, so I will keep adding them. I also added at least one, and up to five images with each spec sheet, of the Sherman the spec sheet is for. You can click to enlarge all these images, the sizes very.

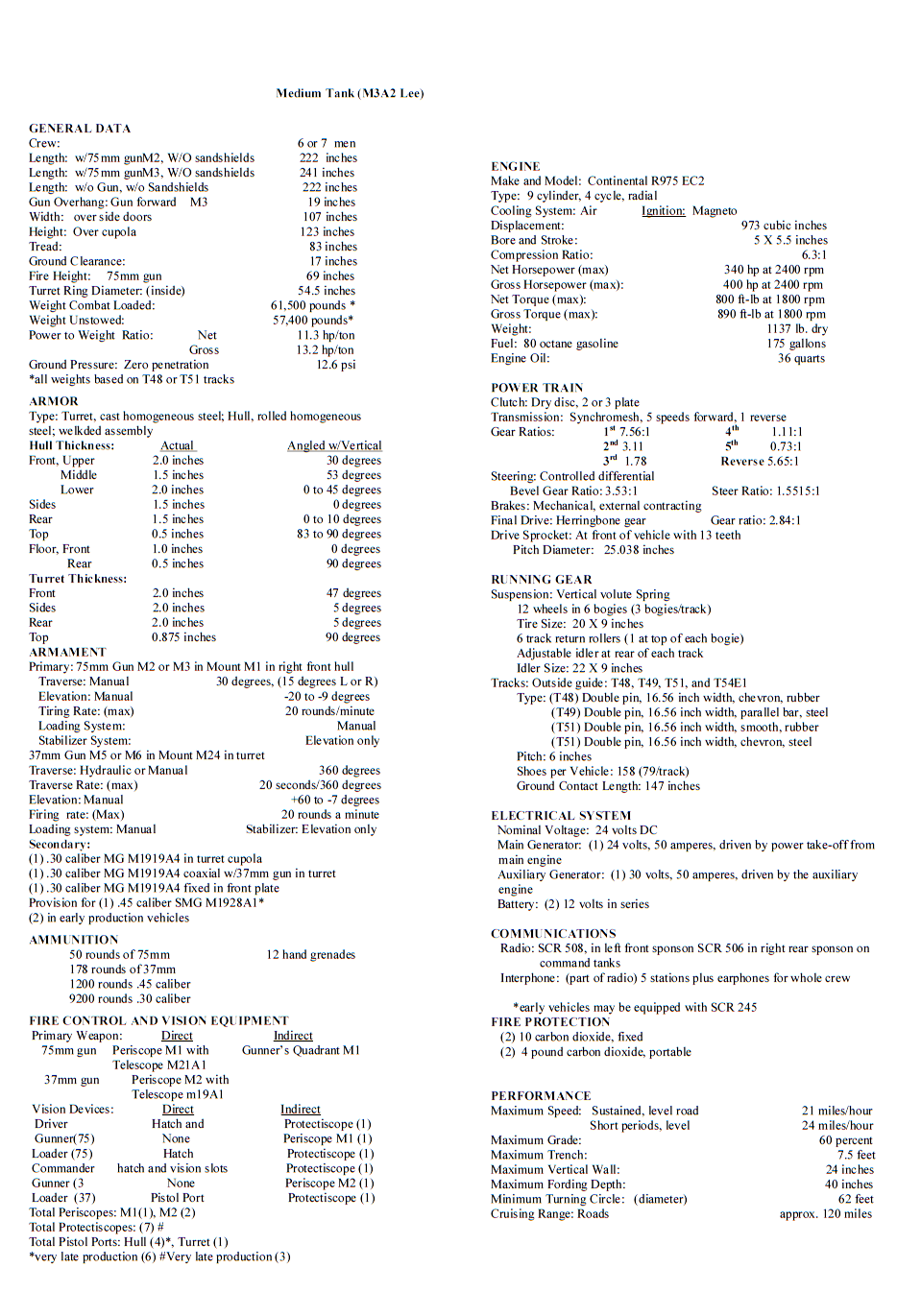

M3 Lee spec Sheet

M3 Lee spec sheet in PDF

M3A2 Spec Sheet

M3A2 Lee Spec Sheet in PDF

Early Production M4 75

M4 Early spec sheet

Early M4A1 75

Mid Production M4A1 75

M4A1 75 mid war spec sheet

Mid production M4A2 75

M4A2 75 mid production spec sheet

Mid production M4A3 75

M4A3 75d mid spec sheet

M4A3 75 wet large hatch VVSS

Early M4A4 75

Early M4A1 75

Mid Production M4A1 75

M4A1 75 mid war spec sheet

Mid production M4A2 75

M4A2 75 mid production spec sheet

Mid production M4A3 75

M4A3 75d mid spec sheet

M4A3 75 wet large hatch VVSS

Early M4A4 75

Early M4A1 75

Mid Production M4A1 75

M4A1 75 mid war spec sheet

Mid production M4A2 75

M4A2 75 mid production spec sheet

Mid production M4A3 75

M4A3 75d mid spec sheet

M4A3 75 wet large hatch VVSS

Early M4A4 75

M4A1 76 wet VVSS

M4A2 76 wet VVSS

M4A2 76w spec sheet

M4A2 76 wet HVSS

M4A2 76w HVSS Easy 8 Spec Sheet

M4A3 76 wet HVSS, or Sherman Easy 8

The M4A3E2 Jumbo 75

Sherman Firefly VC

M10 GMC

M36 GMC

M36B1 90mm GMC

Old School Brit

What Every Gun Lover needs!

The Howdah Gun

Now back in the Glory Days of the British Empire and the Raj. If you were very rich or had gotten in trouble at home.

The Thing to do was to escape Blighty and head out to one of the Colonies. Especially if you were greedy & or Blood thirsty. Even more especially after the Sepoy Mutiny.

So as you went East of Suez. You would of course be invited to a Tiger Hunt. If you were of the right sort of chap naturally.

Yeah right, uh moving on.

How the Howah was usually used. Now back in the day. They way one properly hunted Tigers in India was on top of an Elephant.

If a Tiger decided to come join you in your basket. Then you had your handy dandy Howdah guns to greet him with. So as you can guess by now. These guns packed quite a punch.

The Howdah Pistol can also be very useful in Labor Negotiations with the locals at times. (Film The Ghost & The Darkness. Great Film by the way)

Anyways here is some other videos and other information about these heavy hitters.

Howdah pistol

Double barrel .50 caliber (13mm) howdah pistol made in Germany

The howdah pistol was a large-calibre handgun, often with two or four barrels, used in India and Africa from the beginning of the nineteenth century, and into the early twentieth century, during the period of British Colonial rule. It was typically intended for defence against tigers, lions, and other dangerous animals that might be encountered in remote areas. Multi-barreled breech-loading designs were later favoured over the original muzzle-loading designs for Howdah pistols, because they offered faster reloading than was possible with contemporary revolvers,[1]which had to be loaded and unloaded through a gate in the side of the frame.

The term “howdah pistol” comes from the howdah, a large platform mounted on the back of an elephant. Hunters, especially during the period of the British Raj in India, used howdahs as a platform for hunting wild animals and needed large-calibre side-arms for protection from animal attacks.[2] The practice of hunting from the howdah basket on top of an Asian elephant was first made popular by the joint Anglo-Indian East India Company during the 1790s. These earliest howdah pistols were flintlock designs, and it was not until about 60 years later percussion models in single or double barrel configuration were seen. By the 1890s and early 1900s cartridge-firing and fully rifled howdah pistols were in normal, everyday use.

The first breech-loading howdah pistols were little more than sawn-off rifles,[2]typically in .577 Snider[3] or .577/450 Martini–Henry calibre. Later English firearms makers manufactured specially-designed howdah pistols[3] in both rifle calibres and more conventional handgun calibres such as .455 Webley and .476 Enfield.[2]As a result, the term “howdah pistol” is often applied to a number of English multi-barrelled handguns such as the Lancaster pistol (available in a variety of calibres from .380″ to .577″),[4] and various .577 calibre revolvers produced in England and Europe for a brief time in the mid-late 19th century.[5]

Even though howdah pistols were designed for emergency defense from dangerous animals in Africa and India, British officers adopted them for personal protection in other far-flung outposts of the British Empire.[3] By the late 19th century, top-break revolvers in more practical calibres (such as .455 Webley) had become widespread,[3] removing much of the traditional market for howdah pistols.

Modern reproductions are available from Italian gun maker Pedersoli in .577 and .50 calibers, as well as in 20 bore.

Now you are probably saying right now.”WTF is this Grumpy?” And I would have to agree that this is not your average semi auto pistol.

So here is what I found out about it.

Enjoy!

Somebody else wrote this one. AS you can guess. Since it is a whole lot better written than I could.

The model 1898 Schwarzlose was a self loading pistol definitely ahead of its time. It was simple, powerful (for the period; it was chambered for 7.63mm Mauser), and remarkably ergonomic. It used a short recoil, rotating bolt mechanism to operate, and very cleverly had one single spring which did the duties of primary recoil spring, striker spring, trigger spring, and extractor spring. Why it failed to become a commercial success is a question I have not been able to definitively answer – I suspect it must have been due to cost. Edward Ezell theorizes that it was unable to compete with the Borchardt/Luger and Mauser pistols because those were able to be made with much more economy of scale. It is really a shame, because the Schwarzlose 1898 is the best of all the pre-1900 handguns I have encountered.

Lee–Enfield

| Lee–Enfield | |

|---|---|

Short Magazine Lee–Enfield Mk I (1903), Swedish Army Museum, Stockholm.

|

|

| Type | Bolt-action rifle |

| Place of origin | United Kingdom |

| Service history | |

| In service | MLE: 1895–1926 SMLE: 1904–present |

| Used by | See Users |

| Wars | Second Boer War World War I Easter Rising Various Colonial conflicts Irish War of Independence Irish Civil War World War II Indonesian National Revolution Indo-Pakistani Wars Greek Civil War Malayan Emergency French Indochina War Korean War Arab-Israeli War Suez Crisis Border Campaign (Irish Republican Army) Mau Mau Uprising Vietnam War The Troubles Sino-Indian War Bangladesh Liberation War Soviet invasion of Afghanistan Nepalese Civil War Afghanistan conflict |

| Production history | |

| Designer | James Paris Lee, RSAF Enfield |

| Produced | MLE: 1895–1904 SMLE: 1904–present |

| No. built | 17,000,000+[1] |

| Variants | See Models/marks |

| Specifications | |

| Weight | 4.19 kg (9.24 lb) (Mk I) 3.96 kg (8.73 lb) (Mk III) 4.11 kg (9.06 lb) (No. 4) |

| Length | MLE: 49.6 in (1,260 mm) SMLE No. 1 Mk III: 44.57 in (1,132 mm) SMLE No. 4 Mk I: 44.45 in (1,129 mm) LEC: 40.6 in (1,030 mm) SMLE No. 5 Mk I: 39.5 in (1,003 mm) |

| Barrel length | MLE: 30.2 in (767 mm) SMLE No. 1 Mk III: 25.2 in (640 mm) SMLE No. 4 Mk I: 25.2 in (640 mm) LEC: 21.2 in (540 mm) SMLE No. 5 Mk I: 18.8 in (480 mm) |

|

|

|

| Cartridge | .303 Mk VII SAA Ball |

| Action | Bolt-action |

| Rate of fire | 20–30 aimed shots per minute |

| Muzzle velocity | 744 m/s (2,441 ft/s) |

| Effective firing range | 550 yd (503 m)[2] |

| Maximum firing range | 3,000 yd (2,743 m)[2] |

| Feed system | 10-round magazine, loaded with 5-round charger clips |

| Sights | Sliding ramp rear sights, fixed-post front sights, “dial” long-range volley; telescopic sights on sniper models. Fixed and adjustable aperture sights incorporated onto later variants. |

The Lee–Enfield is a bolt-action, magazine-fed, repeating rifle that was the main firearm used by the military forces of the British Empireand Commonwealth during the first half of the 20th century. It was the British Army‘s standard rifle from its official adoption in 1895 until 1957.[3][4]. It is often referred to as the “SMLE,” which is short for “Short Magazine Lee-Enfield”.

A redesign of the Lee–Metford (adopted by the British Army in 1888), the Lee–Enfield superseded the earlier Martini–Henry, Martini–Enfield, and Lee–Metford rifles. It featured a ten-round box magazine which was loaded with the .303 Britishcartridge manually from the top, either one round at a time or by means of five-round chargers. The Lee–Enfield was the standard issue weapon to rifle companies of the British Army and other Commonwealth nations in both the Firstand Second World Wars (these Commonwealth nations included Australia, New Zealand, Canada, India and South Africa, among others).[5] Although officially replaced in the UK with the L1A1 SLR in 1957, it remained in widespread British service until the early/mid-1960s and the 7.62 mm L42 sniper variant remained in service until the 1990s. As a standard-issue infantry rifle, it is still found in service in the armed forces of some Commonwealth nations,[6] notably with the Bangladesh Police, which makes it the second longest-serving military bolt-action rifle still in official service, after the Mosin–Nagant.[7] The Canadian Rangers reserve unit still use Enfield rifles, with plans to replace the weapons sometime in 2017–2018 with the new Sako-designed Colt C-19.[8] Total production of all Lee–Enfields is estimated at over 17 million rifles.[1]

The Lee–Enfield takes its name from the designer of the rifle’s bolt system—James Paris Lee—and the factory in which it was designed—the Royal Small Arms Factory in Enfield. In Australia, Canada, New Zealand, Southern Africa and India the rifle became known simply as the “three-oh-three“[9] or the “three-naught-three“.

Contents

[hide]

- 1Design and history

- 2Magazine Lee–Enfield

- 3Short Magazine Lee–Enfield Mk I

- 4Short Magazine Lee–Enfield Mk III

- 5Pattern 1914/US M1917

- 6Inter-war period

- 7Lee–Enfield No. 1 Mk V

- 8Rifle No. 4

- 9Rifle No. 5 Mk I—the “Jungle Carbine”

- 10Lee–Enfield conversions and training models

- 11Special Service Lee–Enfields: Commando and Automatic models

- 12Conversion to 7.62×51mm NATO

- 13Production and manufacturers

- 14The Lee–Enfield in military/police use today

- 15The Lee–Enfield in civilian use

- 16Users

- 17See also

- 18Notes

- 19References

- 20External links

Design and history

The Lee–Enfield rifle was derived from the earlier Lee–Metford, a mechanically similar black-powder rifle, which combined James Paris Lee‘s rear-locking bolt system with a barrel featuring rifling designed by William Ellis Metford. The Lee action cocked the striker on the closing stroke of the bolt, making the initial opening much faster and easier compared to the “cock on opening” (i.e., the firing pin cocks upon opening the bolt) of the Mauser Gewehr 98 design. The rear-mounted lugs place the bolt operating handle much closer to the operator, over the trigger, making it quicker to operate than traditional designs like the Mauser.[4] The action features helical locking surfaces (the technical term is interrupted threading). This means that final head space is not achieved until the bolt handle is turned down all the way. The British probably used helical locking lugs to allow for chambering imperfect or dirty ammunition and that the closing cam action is distributed over the entire mating faces of both bolt and receiver lugs. This is one reason the bolt closure feels smooth. The rifle was also equipped with a detachable sheet-steel, 10-round, double-column magazine, a very modern development in its day. Originally, the concept of a detachable magazine was opposed in some British Army circles, as some feared that the private soldier might be likely to lose the magazine during field campaigns. Early models of the Lee–Metford and Lee–Enfield even used a short length of chain to secure the magazine to the rifle.[10]

The fast-operating Lee bolt-action and 10-round magazine capacity enabled a well-trained rifleman to perform the “mad minute” firing 20 to 30 aimed rounds in 60 seconds, making the Lee–Enfield the fastest military bolt-action rifle of the day. The current world record for aimed bolt-action fire was set in 1914 by a musketry instructor in the British Army—Sergeant Instructor Snoxall—who placed 38 rounds into a 12-inch-wide (300 mm) target at 300 yards (270 m) in one minute.[11]Some straight-pull bolt-action rifles were thought faster, but lacked the simplicity, reliability, and generous magazine capacity of the Lee–Enfield. Several First World War accounts tell of British troops repelling German attackers who subsequently reported that they had encountered machine guns, when in fact it was simply a group of well-trained riflemen armed with SMLE Mk III rifles.[12][13]

The Lee–Enfield was adapted to fire the .303 British service cartridge, a rimmed, high-powered rifle round. Experiments with smokeless powder in the existing Lee–Metford cartridge seemed at first to be a simple upgrade, but the greater heat and pressure generated by the new smokeless powder wore away the shallow, rounded, Metford rifling after approximately 6000 rounds.[3] Replacing this with a new square-shaped rifling system designed at the Royal Small Arms Factory (RSAF) Enfield solved the problem, and the Lee–Enfield was born.[3]

Models/marks of Lee–Enfield Rifle and service periods

-

Model/Mark In Service Magazine Lee–Enfield 1895–1926 Charger Loading Lee–Enfield 1906–1926 Short Magazine Lee–Enfield Mk I 1904–1926 Short Magazine Lee–Enfield Mk II 1906–1927 Short Magazine Lee–Enfield Mk III/III* 1907–present Short Magazine Lee–Enfield Mk V 1922–1924 (trials only; 20,000 produced) Rifle No. 1 Mk VI 1930–1933 (trials only; 1,025 produced) Rifle No. 4 Mk I 1931–present (2,500 trials examples produced in the 1930s, then mass production from mid-1941 onwards) Rifle No. 4 Mk I* 1942–present Rifle No 5 Mk I “Jungle Carbine” 1944–present (produced 1944–1947) BSA-Shirley produced 81,329 rifles and ROF Fazakerley 169,807 rifles. Rifle No. 4 Mk 2 1949–present Rifle 7.62mm 2A 1964–present Rifle 7.62mm 2A1 1965–present

Magazine Lee–Enfield

The Lee–Enfield rifle was introduced in November 1895 as the .303 calibre, Rifle, Magazine, Lee–Enfield,[3] or more commonly Magazine Lee–Enfield, or MLE (sometimes spoken as “emily” instead of M, L, E). The next year, a shorter version was introduced as the Lee–Enfield Cavalry Carbine Mk I, or LEC, with a 21.2-inch (540 mm) barrel as opposed to the 30.2-inch (770 mm) one in the “long” version.[3] Both underwent a minor upgrade series in 1899 (the omission of the cleaning / clearing rod), becoming the Mk I*.[14] Many LECs (and LMCs in smaller numbers) were converted to special patterns, namely the New Zealand Carbine and the Royal Irish Constabulary Carbine, or NZ and RIC carbines, respectively.[15] Some of the MLEs (and MLMs) were converted to load from chargers, and designated Charger Loading Lee–Enfields, or CLLEs.[16]

Short Magazine Lee–Enfield Mk I

A shorter and lighter version of the original MLE—the famous Rifle, Short, Magazine, Lee–Enfield, or SMLE (sometimes spoken as “Smelly”, rather than S, M, L, E)[7]—was introduced on 1 January 1904.[17] The barrel was now halfway in length between the original long rifle and the carbine, at 25.2 inches (640 mm).[17]

The SMLE’s visual trademark was its blunt nose, with only the bayonet boss protruding a small fraction of an inch beyond the nosecap, being modeled on the Swedish Model 1894 Cavalry Carbine. The new rifle also incorporated a charger loading system,[18] another innovation borrowed from the Mauser rifle’[19] and is notably different from the fixed “bridge” that later became the standard, being a charger clip (stripper clip) guide on the face of the bolt head. The shorter length was controversial at the time: many Rifle Association members and gunsmiths were concerned that the shorter barrel would not be as accurate as the longer MLE barrels, that the recoil would be much greater, and the sighting radius would be too short.[20]

Short Magazine Lee–Enfield Mk III

The iconic Lee–Enfield rifle, the SMLE Mk III, was introduced on 26 January 1907, along with a Pattern 1907 (P’07) sword bayonet and featured a simplified rear sight arrangement and a fixed, rather than a bolt-head-mounted sliding, charger guide.[7] The design of the handguards and the magazine were also improved, and the chamber was adapted to fire the new Mk VII High Velocity spitzer .303 ammunition. Many early model rifles, of Magazine Lee–Enfield (MLE), Magazine Lee–Metford (MLM), and SMLE type, were upgraded to the Mk III standard. These are designated Mk IV Cond., with various asterisks denoting subtypes.[21]

During the First World War, the SMLE Mk III was found to be too complicated to manufacture (an SMLE Mk III rifle cost the British Government £3/15/-) and demand was outstripping supply, so in late 1915 the Mk III* was introduced, which incorporated several changes, the most prominent of which were the deletion of the magazine cut-off mechanism, which when engaged permits the feeding and extraction of single cartridges only while keeping the cartridges in the magazine in reserve, and the long-range volley sights.[19][21][22][23] The windage adjustment of the rear sight was also dispensed with, and the cocking piece was changed from a round knob to a serrated slab.[23] Rifles with some or all of these features present are found, as the changes were implemented at different times in different factories and as stocks of existing parts were used.[24] The magazine cut-off was reinstated after the First World War ended and not entirely dispensed with until 1942.[23]

The inability of the principal manufacturers (RSAF Enfield, The Birmingham Small Arms Company Limited and London Small Arms Co. Ltd) to meet military production demands, led to the development of the “peddled scheme”, which contracted out the production of whole rifles and rifle components to several shell companies.[25]

The SMLE Mk III* (renamed Rifle No.1 Mk III* in 1926) saw extensive service throughout the Second World War as well, especially in the North African, Italian, Pacific and Burmese theatres in the hands of British and Commonwealth forces. Australia and India retained and manufactured the SMLE Mk III* as their standard-issue rifle during the conflict and the rifle remained in Australian military service through the Korean War, until it was replaced by the L1A1 SLR in the late 1950s.[26] The Lithgow Small Arms Factory finally ceased production of the SMLE Mk III* in 1953.[21]

The Rifle Factory at Ishapore, West Bengal, India produced the MkIII* in .303 British and then upgraded the manufactured strength by heat treatment of the receiver and bolt to fire 7.62×51mm NATO ammunition, the model 2A, which retained the 2000 yard rear sight as the metric conversion of distance was very close to the flatter trajectory of the new ammunition nature, then changed the rear sight to 800m with a re-designation to model 2A1. Manufactured until at least the 1980s and continues to produce a sporting rifle based on the MkIII* action.

Pattern 1913 Enfield

Due to the poor performance of the .303 British cartridge during the Second Boer War from 1899–1902, the British attempted to replace the round and the Lee–Enfield rifle that fired it. The main deficiency of the rounds at the time was that they used heavy, round-nosed bullets that had low muzzle velocities and poor ballistic performance. The 7mm Mauserrounds fired from the Mauser Model 1895 rifle had a higher velocity, flatter trajectory and longer range, making them superior on the open country of the South African plains. Work on a long-range replacement cartridge began in 1910 and resulted in the .276 Enfield in 1912. A new rifle based on the Mauser design was created to fire the round, called the Pattern 1913 Enfield. Although the .276 Enfield had better ballistics, troop trials in 1913 revealed problems including excessive recoil, muzzle flash, barrel wear and overheating. Attempts were made to find a cooler-burning propellant but further trials were halted in 1914 by the onset of World War I. This proved fortunate for the Lee–Enfield, as wartime demand and the improved Mk VII loading of the .303 round, caused it to be retained for service.[27]

Pattern 1914/US M1917

The Pattern 1914 Enfield and M1917 Enfield rifles are based on the Enfield-designed P1913, itself a Mauser 98 derivative and not based on the Lee action, and are not part of the Lee–Enfield family of rifles, although they are frequently assumed to be.[28]

Inter-war period

In 1926, the British Army changed their nomenclature; the SMLE became known as the Rifle No. 1 Mk III or III*, with the original MLE and LEC becoming obsolete along with the earlier SMLE models.[29] Many Mk III and III* rifles were converted to .22 rimfire calibre training rifles, and designated Rifle No. 2, of varying marks. (The Pattern 1914 became the Rifle No. 3.)[29]

The SMLE design was a relatively expensive long arm to manufacture, because of the many forging and machiningoperations required. In the 1920s, a series of experiments resulting in design changes were carried out to help with these problems, reducing the number of complex parts and refining manufacturing processes. The SMLE Mk V (later Rifle No. 1 Mk V), adopted a new receiver-mounted aperture sighting system, which moved the rear sight from its former position on the barrel.[30] The increased gap resulted in an improved sighting radius, improving sighting accuracy and the aperture improved speed of sighting over various distances. In the stowed position, a fixed distance aperture battle sight calibrated for 300 yd (274 m) protruded saving further precious seconds when laying the sight to a target. An alternative developed during this period was to be used on the No. 4 variant, a “battle sight” was developed that allowed for two set distances of 300 yards and 600 yards to be quickly deployed and was cheaper to produce than the “ladder sight”. The magazine cutoff was also reintroduced and an additional band was added near the muzzle for additional strength during bayonet use.[30] The design was found to be even more complicated and expensive to manufacture than the Mk III and was not developed or issued, beyond a trial production of about 20,000 rifles between 1922 and 1924 at RSAF Enfield.[30] The No. 1 Mk VI also introduced a heavier “floating barrel” that was independent of the forearm, allowing the barrel to expand and contract without contacting the forearm and interfering with the ‘zero’, the correlation between the alignment of the barrel and the sights. The floating barrel increased the accuracy of the rifle by allowing it to vibrate freely and consistently, whereas wooden forends in contact with barrels, if not properly fitted, affected the harmonic vibrations of the barrel. The receiver-mounted rear sights and magazine cutoff were also present and 1,025 units were produced between 1930 and 1933.[31]

Lee–Enfield No. 1 Mk V

Long before the No. 4 Mk I, Britain had obviously settled on the rear aperture sight prior to WWI, with modifications to the SMLE being tested as early as 1911, as well as later on the No. 1 Mk III pattern rifle. These unusual rifles have something of a mysterious service history, but represent a missing link in SMLE development. The primary distinguishing feature of the No. 1 Mk V is the rear aperture sight. Like the No. 1 Mk III* it lacked a volley sight and had the wire loop in place of the sling swivel at the front of magazine well along with the simplified cocking piece. The Mk V did retain a magazine cut-off, but without a spotting hole, the piling swivel was kept attached to a forward barrel band, which was wrapped over and attached to the rear of the nose cap to reinforce the rifle for use with the standard Pattern 1907 bayonet. Other distinctive features include a nose cap screw was slotted for the width of a coin for easy removal, a safety lever on the left side of the receiver was slightly modified with a unique angular groove pattern, and the two-piece hand guard being extended from the nose cap to the receiver, omitting the barrel mounted leaf sight. No. 1 Mk V rifles were manufactured solely by R.S.A.F. Enfield from 1922–1924, with a total production of roughly 20,000 rifles, all of which marked with a “V”.

Rifle No. 4

By the late 1930s, the need for new rifles grew and the Rifle, No. 4 Mk I was officially adopted in 1941.[32] The No. 4 action was similar to the Mk VI, but stronger and most importantly, easier to mass-produce.[33] Unlike the SMLE, that had a nose cap, the No 4 Lee–Enfield barrel protruded from the end of the forestock. The charger bridge was no longer rounded for easier machining. The iron sightline was redesigned and featured a rear receiver aperture battle sight calibrated for 300 yd (274 m) with an additional ladder aperture sight that could be flipped up and was calibrated for 200–1,300 yd (183–1,189 m) in 100 yd (91 m) increments. This sight line like other aperture sight lines proved to be faster and more accurate than the typical mid-barrel rear sight elements sight lines offered by Mauser, previous Lee–Enfields or the Buffington battle sight of the 1903 Springfield.

The No. 4 rifle was heavier than the No. 1 Mk. III, largely due to its heavier barrel and a new bayonet was designed to go with the rifle: a spike bayonet, which was essentially a steel rod with a sharp point and was nicknamed “pigsticker” by soldiers.[33] Towards the end of the Second World War, a bladed bayonet was developed, originally intended for use with the Sten gun—but sharing the same mount as the No. 4’s spike bayonet—and subsequently the No. 7 and No. 9 blade bayonets were issued for use with the No. 4 rifle as well.[34]However, in McAuslan in the Rough, George MacDonald Fraser alleges that the Pattern 1907 bladed bayonet used with the SMLE was also compatible with the No. 4 rifle.[35]

During the course of the Second World War, the No. 4 rifle was further simplified for mass-production with the creation of the No. 4 Mk I* in 1942, with the bolt release catch replaced by a simpler notch on the bolt track of the rifle’s receiver.[36] It was produced only in North America, by Long Branch Arsenal in Canada and Savage-Stevens Firearms in the USA.[36]The No.4 Mk I rifle was primarily produced for the United Kingdom.[37]

In the years after the Second World War, the British produced the No. 4 Mk 2 (

…

[Message clipped] View entire message

Colt Python

| Colt Python | |

|---|---|

Colt Pythons with 6-inch (15 cm) and 4-inch (10 cm) barrels and nickel finish

|

|

| Type | Revolver |

| Place of origin | United States |

| Production history | |

| Manufacturer | Colt’s Manufacturing Company |

| Produced | 1955–2005 |

| Variants | 2.5-inch (6.4 cm), 3-inch (7.6 cm), 4-inch (10 cm), 6-inch (15 cm) and 8-inch (20 cm) barrel |

| Specifications | |

| Weight | 38 ounces (1.1 kg) to 48 ounces (1.4 kg) |

|

|

|

| Cartridge | .357 Magnum |

| Action | Double-action |

| Maximum firing range | 75 yrds |

| Feed system | Six-round cylinder |

| Sights | Rear adj.; front ramp |

The Colt Python is a .357 Magnum caliber revolver formerly manufactured by Colt’s Manufacturing Company of Hartford, Connecticut. It is sometimes referred to as a “Combat Magnum”.[1] It was first introduced in 1955, the same year as Smith & Wesson’s M29 .44 Magnum. Now discontinued, the Colt Python targeted the premium revolver market segment. Some firearm collectors and writers such as Jeff Cooper, Ian V. Hogg, Chuck Hawks, Leroy Thompson, Scott Wolber, Renee Smeets and Martin Dougherty have described the Python as the finest production revolver ever made.[1][2][3][4][5][6][7]

Contents

[hide]

Description[edit]

The Colt Python is a double action handgun chambered for the .357 Magnum cartridge, built on Colt’s large I-frame. Pythons have a reputation for accuracy, smooth trigger pull, and a tight cylinder lock-up.[2] They are similar in size and function to the Colt Trooper and Colt Lawman revolvers.[8]

History[edit]

The Colt Python was first introduced in 1955 as Colt’s top-of-the-line model and was originally intended to be a large-frame 38 Special target revolver.[3] As a result, it features precision adjustable sights, a smooth trigger, solid construction, and extra metal. Pythons have a distinct appearance due to a full barrel underlug, ventilated rib and adjustable sights.[3] Originally, Colt manufactured Pythons with hollow underlugs but left them solid to work as a stabilizing barrel weight. When the revolver is at full cock, just as the trigger is pressed, the cylinder locks up for the duration of the hammer strike. Other revolvers have a hint of looseness even at full-cock. The gap between the cylinder and forcing cone is very tight, further aiding accuracy and velocity.[2] Starting in the 1970s each Python revolver was boresighted at the factory with a laser and was the first mass-produced revolver to do so.[3]

End of production[edit]

In October 1999, Colt Manufacturing Co. announced the termination of its production of Python revolvers. In a 2000 follow-up letter to distributors, the company cited changing market conditions and the costs of defending lawsuits as the reasons for the discontinuation of the Python line as well as a number of other models.[9] The Colt Custom Gun Shop continued making a limited number of Pythons on special order until 2005, when even this limited production was terminated.[2][10]

Models and variants[edit]

The Python was originally available in two finishes: Royal Blue and Bright Nickel. The Bright Nickel model was discontinued with the introduction of the more durable satin stainless and mirror-polished Ultimate Stainless models.[2] The stainless steel and Royal Blue finishes were offered until 2003 by Colt on the Python “Elite” model.[8]

Pythons were available with 2.5-inch (6.4 cm), 3-inch (7.6 cm), 4-inch (10 cm), 6-inch (15 cm) and 8-inch (20 cm) barrels.[2] The six-inch model was the most popular generally, and the 8-inch model was intended for hunting. A 3-inch barrel version is very collectible, although not rare.[3]

The Python Hunter model, with 8-inch barrel and factory-installed 2X Leupoldscope, was made in 1980.[11] The Python Hunter was the first field-ready handgun hunting package made by a major handgun manufacturer.[11] The scope was mounted on the barrel using Redfield mounts and the gun was packaged in a Haliburton case.[11] It was discontinued by 1990 and briefly offered as a “Custom Shop” model afterward.[11] A Python Target model was made for several years in .38 Special only, in blue and nickel finishes.[8]

Two variants of the Python were made in small numbers by Colt. The first was the Colt Boa of 1985, a limited production .357 Magnum revolver, made for the Lew Horton Distributing Company in Massachusetts. It used a Python barrel mated to a Trooper Mk V frame. Six hundred 6-inch revolvers and 600 4-inch revolvers were made, of which 100 were matched sets. Though it resembles a Python visually, it is substantially different internally. The second was the stainless steel Colt Grizzly of 1994, another limited production .357 Magnum revolver. It used a Python barrel mated to a Colt King Cobraframe. 500 of these revolvers were manufactured, with 6-inch Magna-Ported barrels and smooth, unfluted cylinders. The ported barrel includes a bear footprint. Similar to the Grizzly was the Colt Kodiak, which was a Colt Anaconda with a Magna-Ported Barrel and an unfluted cylinder. Approximately 2000 Kodiaks were manufactured.[8]

According to Colt historian, R.L. Wilson, Colt Pythons have been collected by Elvis Presley and various kings in the traditional sense: “H.M. (His Majesty) Hussein I of Jordan ordered a limited number of Pythons with 4-inch and 6-inch barrels, as gifts to his selected friends. Casing and barrel were embossed with His Majesty’s crest. The Python for King Juan Carlos of Spain bore his name in flush gold on the sideplate. Among other celebrated recipients: King Khalid and Prince Fahd (Saudi Arabia), King Hassan (Morocco), Sheik Zayed (United Arab Emirates), President Anwar Sadat (Egypt) and President Hafez Assad (Syria).”[4]

Usage[edit]

The Python immediately made inroads into the law enforcement market when introduced, with the 6-inch barrel being popular with uniformed officers and the 4-inch barrel considered optimum for plainclothes use.[3] However, it has since fallen out of common use (along with all other revolvers) due to changing law enforcement needs that favor semi-automatic pistols. When law-enforcement agencies realized that the 9 mm semi-automatic pistols fire a round with similar characteristics to the .38 Special with higher capacity, they began a migration to these, and other, semi-automatic pistol cartridges.[12][13] The move away from the Python is also being driven by the increasing number of law enforcement agencies which require officers to carry department-issue weapons (as a way to reduce liability).

The Colorado State Patrol issued 4-inch blue Pythons until their switch to the S&W .40 caliber autoloader.[14] Georgia State Patrol and Florida Highway Patrol issued Pythons to their officers.[14]

A Python, loaded with .357 Magnum semiwadcutter bullets, was used to murder Irish crime reporter Veronica Guerin in 1996, an act which resulted in the creation of the Criminal Assets Bureau.[15][16]

Colt’s Python revolvers are still popular on the used market and command high prices.[17]

Criticisms[edit]

Official Colt historian RL Wilson described the Colt Python as “the Rolls-Royce of Colt revolvers”,[4] and firearms historian Ian V. Hogg referred to it as the “best revolver in the world”.[7] However, the revolver is not without its detractors. The downside to the Colt Python’s precision is its tendency to go “out of time” with continued heavy shooting.[18] This is a condition in which the cylinder does not turn in exact alignment with the forcing cone, so a shooter may be sprayed with burning propellant when the gun is fired, or the gun may not fire when used as a double-action.[18] When this happens, the lockwork needs to be re-timed.[18]

Author Martin Dougherty notes the weight of the Python as a drawback, as it is quite heavy for a handgun of its caliber, ranging from 2.4 lbs (1.1 kg) to 2.6 lbs (1.2 kg). This makes it only 6 to 9 ounces lighter than Smith & Wesson‘s more powerful M29 .44 Magnum, which weighs 3.0 lbs in 6½-inch barrel configuration (1.36 kg).[1]

The M-1 Garand

But even then you are doing some pretty good shooting there partner!

M1 Garand

| U.S. rifle, caliber .30, M1 | |

|---|---|

M1 Garand rifle. From the collections of the Swedish Army Museum, Stockholm, Sweden.

|

|

| Type | Semi-automatic rifle |

| Place of origin | United States |

| Service history | |

| In service | 1936–1959 (as the standard U.S. service rifle)1940s–present (other countries) |

| Used by | See Users |

| Wars |

|

| Production history | |

| Designer | John C. Garand |

| Designed | 1928 |

| Manufacturer |

|

| Unit cost | About $85 (during World War II) ($1,200 in 2016 dollars) |

| Produced | 1934—1956 |

| No. built | 5,468,772[3] |

| Variants | M1C, M1D |

| Specifications | |

| Weight | 9.5 lb (4.31 kg) to 11.6 lb (5.3 kg) |

| Length | 43.5 in (1,100 mm) |

| Barrel length | 24 in (609.6 mm) |

|

|

|

| Cartridge |

|

| Action | Gas-operated, rotating bolt |

| Rate of fire | 40−50 rounds/min |

| Muzzle velocity | 2,800 ft/s (853 m/s) |

| Effective firing range | 500 yd (457 m)[4] |

| Feed system | 8-round en-bloc clip, internal magazine |

| Sights |

|

The M1 Garand[nb 1] is a .30 calibersemi-automatic rifle that was the standard U.S. service rifle during World War II and the Korean Warand also saw limited service during the Vietnam War. Most M1 rifles were issued to U.S. forces, though many hundreds of thousands were also provided as foreign aid to American allies. The Garand is still used by drill teams and military honor guards. It is also widely used by civilians for hunting, target shooting, and as a military collectible.

The M1 rifle was named after its Canadian-Americandesigner, John Garand. It was the first standard-issue semi-automatic military rifle.[5]By all accounts the M1 rifle served with distinction. General George S. Patton called it “the greatest battle implement ever devised”.[6][7]The M1 replaced the bolt action M1903 Springfield as the standard U.S. service rifle in the mid 1930s, and was itself replaced by the selective fireM14 rifle in the early 1960s.

Although the name “Garand” is frequently pronounced /ɡəˈrænd/, the preferred pronunciation is /ˈɡærənd/ (to rhyme with errand), according to experts and people who knew John Garand, the weapon’s designer.[8][9] Frequently referred to as the “Garand” or “M1 Garand” by civilians, its official designation when it was the issue rifle in the U.S. Army and the U.S. Marine Corps was “U.S. Rifle, Caliber 30, M1” or just “M1” and Garand was not mentioned.

Contents

[hide]

History

Development

French Canadian-born Garand went to work at the United States Army’s Springfield Armory and began working on a .30 caliber primer actuated blowbackModel 1919 prototype. In 1924, twenty-four rifles, identified as “M1922s”, were built at Springfield. At Fort Benningduring 1925, they were tested against models by Berthier, Hatcher-Bang, Thompson, and Pedersen, the latter two being delayed blowback types.[10] This led to a further trial of an improved “M1924” Garand against the Thompson, ultimately producing an inconclusive report.[10] As a result, the Ordnance Board ordered a .30-06 Garand variant. In March 1927, the cavalry board reported trials among the Thompson, Garand, and 03 Springfield had not led to a clear winner. This led to a gas-operated .276 (7 mm) model (patented by Garand on 12 April 1930).[10]

In early 1928, both the infantry and cavalryboards ran trials with the .276 Pedersen T1 rifle, calling it “highly promising”[10] (despite its use of waxedammunition,[11] shared by the Thompson).[12] On 13 August 1928, a semiautomatic rifle board (SRB) carried out joint Army, Navy, and Marine Corpstrials between the .30 Thompson, both cavalry and infantry versions of the T1 Pedersen, “M1924” Garand, and .256 Bang, and on 21 September, the board reported no clear winner. The .30 Garand, however, was dropped in favor of the .276.[13]

Further tests by the SRB in July 1929, which included rifle designs by Browning, Colt–Browning, Garand, Holek, Pedersen, Rheinmetall, Thompson, and an incomplete one by White,[nb 2] led to a recommendation that work on the (dropped) .30 gas-operated Garand be resumed, and a T1E1 was ordered 14 November 1929.

Twenty gas-operated .276 T3E2 Garands were made and competed with T1 Pedersen rifles in early 1931. The .276 Garand was the clear winner of these trials. The .30 caliber Garand was also tested, in the form of a single T1E1, but was withdrawn with a cracked bolt on 9 October 1931. A 4 January 1932 meeting recommended adoption of the .276 caliber and production of approximately 125 T3E2s. Meanwhile, Garand redesigned his bolt and his improved T1E2 rifle was retested. The day after the successful conclusion of this test, Army Chief of StaffGeneral Douglas MacArthur personally disapproved any caliber change, in part because there were extensive existing stocks of .30 M1 ball ammunition.[14] On 25 February 1932, Adjutant General John B. Shuman, speaking for the secretary of war, ordered work on the rifles and ammunition in .276 caliber cease immediately and completely and all resources be directed toward identification and correction of deficiencies in the Garand .30 caliber.[12]:111

On 3 August 1933, the T1E2 became the “semi-automatic rifle, caliber 30, M1”.[10] In May 1934, 75 M1s went to field trials; 50 were to infantry, 25 to cavalry units.[12]:113 Numerous problems were reported, forcing the rifle to be modified, yet again, before it could be recommended for service and cleared for procurement on 7 November 1935, then standardized 9 January 1936.[10] The first production model was successfully proof-fired, function-fired, and fired for accuracy on July 21, 1937.[15]

Production difficulties delayed deliveries to the army until September 1937. Machine production began at Springfield Armory that month at a rate of ten rifles per day,[16] and reached an output of 100 per day within two years. Despite going into production status, design issues were not at an end. The barrel, gas cylinder, and front sight assembly were redesigned and entered production in early 1940. Existing “gas-trap” rifles were recalled and retrofitted, mirroring problems with the earlier M1903 Springfield rifle that also had to be recalled and reworked approximately three years into production and foreshadowing rework of the M16 rifle at a similar point in its development. Production of the Garand increased in 1940 despite these difficulties,[17] reaching 600 a day by 10 January 1941,[10] and the army was fully equipped by the end of 1941.[14] Following the outbreak of World War II in Europe, Winchester was awarded an “educational” production contract for 65,000 rifles,[10] with deliveries beginning in 1943.[10]

Service use

The M1 Garand was made in large numbers during World War II, approximately 5.4 million were made.[18]They were used by every branch of the United States military. By all accounts the M1 rifle served with distinction. General George S. Patton called it “the greatest implement of battle ever devised.”[7] The impact of faster-firing infantry small arms in general soon stimulated both Allied and Axis forces to greatly increase their issue of semi- and fully automaticfirearms then in production, as well as to develop new types of infantry firearms.[19]

Much of the M1 inventory in the post-World War II period underwent arsenal repair or rebuilding. While U.S. forces were still engaged in the Korean War, the Department of Defense determined a need for additional production of the Garand. Springfield Armory ramped up production but two new contracts were awarded. During 1953–56, M1s were produced by International Harvesterand Harrington & Richardson in which International Harvester alone produced a total of 337,623 M1 Garands.[20][21] A final, very small lot of M1s was produced by Springfield Armory in early 1957, using finished components already on hand. Beretta also produced Garands using Winchester tooling.

The British Army looked at the M1 as a possible replacement for its bolt-action Lee–Enfield No.1 Mk III, but it was rejected when rigorous testing suggested that it was an unreliable weapon in muddy conditions.[22][23] However, surplus M1 rifles were provided as foreign aid to American allies; including South Korea, West Germany, Italy, Japan, Denmark, Greece, Turkey, Iran, South Vietnam, etc. Most Garands shipped to allied nations were predominantly manufactured by International Harvester Corporation during the period of 1953-56, and second from Springfield Armory from all periods.[24]

Some Garands were still being used by the United States into the Vietnam War in 1963; despite the M14’s official adoption in 1957, it was not until 1965 the changeover from the M1 Garand was completed in the active-duty component of the army (with the exception of the sniper variants, which were introduced in World War II and saw action in Korea and Vietnam). The Garand remained in service with the Army Reserve, Army National Guard and the Navy, well into the 1970s or longer.

Due to widespread United States military assistance as well their durability, M1 Garands have also been turning up in modern conflicts such as with the insurgencies in Iraq and Afghanistan.[25]

Some military drill teams still use the M1 rifle, including the U.S. Marine Corps Silent Drill Team, the United States Air Force Academy Cadet Honor Guard, the U.S. Air Force Auxiliary, almost all Reserve Officer Training Corps (ROTC) and some Junior Reserve Officer Training Corps (JROTC) teams of all branches of the U.S. military.

Design details

Features

The M1 rifle is a .30 caliber, gas-operated, 8 shot clip-fed, semi-automatic rifle.[26] It is 43.6 inches (1,107 mm) long and it weighs about 9.5 pounds (4.31 kg).[27]

The M1’s safety catch is located at the front of the trigger guard. It is engaged when it is pressed rearward into the trigger guard, and disengaged when it is pushed forward and is protruding outside of the trigger guard.[28]

The M1 Garand was designed for simple assembly and disassembly to facilitate field maintenance. It can be field stripped (broken down) without tools in just a few seconds.[29]

The rifle had an iron sight line consisting of rear receiver aperture sight protected by sturdy “ears” calibrated for 100–1,200 yd (91–1,097 m) in 100 yd (91 m) increments. The bullet drop compensation was set by turning the range knob to the appropriate range setting. The bullet drop compensation/range knob can be fine adjusted by setting the rear sight elevation pinion. The elevation pinion can be fine adjusted in approximately 1 MOA increments. The aperture sight was also able to correct for wind drift operated by turning a windage knob that moved the sight in approximately 1 MOA increments. The windage lines on the receiver to indicate the windage setting were 4 MOA apart. The front sighting element consisted of a wing guards protected front post.

During World War II the M1 rifle’s semiautomatic operation gave United States infantrymen a significant advantage in firepower and shot-to-shot recovery time over enemy infantrymen armed primarily with bolt-action rifles. The semi-automatic operation and reduced recoil allowed soldiers to fire 8 rounds as quickly as they could pull the trigger, without having to move their hands on the rifle and therefore disrupt their firing position and point of aim.[30] The Garand’s fire rate, in the hands of a trained soldier, averaged 40–50 accurate shots per minute at a range of 300 yards (270 m). “At ranges over 500 yards (460 m), a battlefield target is hard for the average rifleman to hit. Therefore, 500 yards (460 m) is considered the maximum effective range, even though the rifle is accurate at much greater ranges.”[27]

En bloc clip

The M1 rifle is fed by an “en bloc” clip which holds eight rounds of .30-06 Springfield ammunition. When the last cartridge is fired, the rifle ejects the clip and locks the bolt open.[31] The M1 is now ready to reload. Once the clip is inserted, the bolt snaps forward on its own as soon as thumb pressure is released from the top round of the clip, chambering a round and leaving it ready to fire.[32][33]Although it is not absolutely necessary, the preferred method is to place the back of the right hand against the operating rod handle and press the clip home with the right thumb; this releases the bolt, but the hand restrains the bolt from slamming closed on the operator’s thumb (resulting in “M1 thumb”); the hand is then quickly withdrawn, the operating rod moves forward and the bolt closes with sufficient force to go fully to battery. Thus, after the clip has been pressed into position in the magazine, the operating rod handle should be released, allowing the bolt to snap forward under pressure from the operating rod spring. The operating rod handle may be smacked with the palm to ensure the bolt is closed.[28][33]

Contrary to widespread misconception, partially expended or full clips can be easily ejected from the rifle by means of the clip latch button.[28] It is also possible to load single cartridges into a partially loaded clip while the clip is still in the magazine, but this requires both hands and a bit of practice. In reality, this procedure was rarely performed in combat, as the danger of loading dirt along with the cartridges increased the chances of malfunction. Instead, it was much easier and quicker to simply manually eject the clip, and insert a fresh one,[34]which is how the rifle was originally designed to be operated.[33][35][36] Later, special clips holding two or five rounds became available on the civilian market, as well as a single-loading device which stays in the rifle when the bolt locks back.

In battle, the manual of arms called for the rifle to be fired until empty, and then recharged quickly. Due to the well-developed logistical system of the U.S. military at the time, this wastage of ammunition was generally not critical, though this could change in the case of units that came under intense fire or were flanked or surrounded by enemy forces.[35] The Garand’s en-bloc clip system proved particularly cumbersome when using the rifle to launch grenades, requiring removal of an often partially loaded clip of ball ammunition and replacement with a full clip of blank cartridges.

By modern standards, the M1’s feeding system is archaic, relying on clips to feed ammunition, and is the principal source of criticism of the rifle. Officials in Army Ordnance circles demanded a fixed, non-protruding magazine for the new service rifle. At the time, it was believed that a detachable magazine on a general-issue service rifle would be easily lost by U.S. soldiers (a criticism made of British soldiers and the Lee–Enfield 50 years previously), would render the weapon too susceptible to clogging from dirt and debris (a belief that proved unfounded with the adoption of the M1 Carbine), and that a protruding magazine would complicate existing manual-of-arms drills. As a result, inventor John Garand developed an “en bloc” clip system that allowed ammunition to be inserted from above, clip included, into the fixed magazine. While this design provided the requisite flush-mount magazine, the clip system increased the rifle’s weight and complexity, and made only single loading ammunition possible without a clip.

Ejection of an empty clip created a distinctive metallic “pinging” sound.[37] In World War II, reports arose in which German and Japanese infantry were making use of this noise in combat to alert them to an empty M1 rifle in order to ‘get the drop’ on their American enemies. The information was taken seriously enough that U.S. Army’s Aberdeen Proving Groundbegan experiments with clips made of various plastics in order to soften the sound, though no improved clips were ever adopted.[36] According to former German soldiers, the sound was inaudible during engagements and not particularly useful when heard, as other squad members might have been nearby ready to fire.[38] Seasoned U.S. infantry soldiers would sometimes purposely toss an empty en-bloc clip creating the same sound a Garand makes when it has fired its last shot and is empty, in an effort to draw out the enemy, with varying degrees of success.[39]

Gas system

Garand’s original design for the M1 used a complicated gas system involving a special muzzle extension gas trap, later dropped in favor of a simpler drilled gas port. Because most of the older rifles were retrofitted, pre-1939 gas-trap M1s are very rare today and are prized collector’s items.[26] In both systems, expanding gases from a fired cartridge are diverted into the gas cylinder. Here, the gases meet a long-stroke piston attached to the operating rod, which is pushed rearward by the force of this high-pressure gas. Then, the operating rod engages a rotating bolt inside the receiver. The bolt is attached to the receiver via two locking lugs, which rotate, unlock, and initiate the ejection of the spent cartridge and the reloading cycle when the rifle is discharged. The operating rod (and subsequently the bolt) then returns to its original position.

The M1 Garand was one of the first self-loading rifles to use stainless steel for its gas tube, in an effort to prevent corrosion. As the stainless metal could not be parkerized, the gas tubes were given a stove-blackening that frequently wore off in use. Unless the gas tube could be quickly repainted, the resultant gleaming muzzle could make the M1 Garand and its user more visible to the enemy in combat.[35]

Accessories

Several accessories were used with the Garand rifle. Several different styles of bayonets fit the rifle: the M1905 and M1942, both with 16-inch (406 mm) blades; the Model 1905E1 with shortened 10-inch (254 mm) blade; the M1 with 10-inch (254 mm) blade; and the

…

[Message clipped] View entire message

I do not have a dog in this fight!

BECAUSE

Since I have shot both of them a few times. From which I had a bad experience with both.

But if you folks out there are Happy with what you got. Then all I can say is this!

But if you want. Here is a pretty good video on the subject!

ME, I going shooting with my Sig Saur at the range!

Grumpy