TR At Harvard

The M50 Reising Submachine Gun

Now as any US Marine* will tell you. It seems to them that they are always the last to get any kind of new gear. Especially because the of these facts. As that most of the time. The money comes out of the Navy’s budget. That & the Marine Corp has a well earned reputation for frugality.

Now in the spirit of semi open disclosure. I am one of the few Army Guys that like the Marines for the most part. That is to say. When they are not trying steal everything from us. That is not nailed down with an armed guard on it.

But that is for small minds to ponder upon. Anyways, when WWII came our way. The Marines were having a very hard time getting their hands on Machine Guns. Since it was a seller market at the time.

So when the Sales guy from H&R came around. The Marines snapped them up. In spite of the fact that the Army said a very firm “No Thanks pal! That & do not let the door hit you in the ass on the way out”.

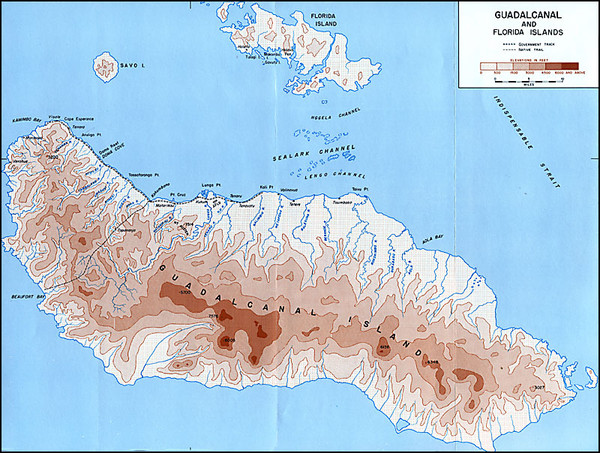

As the Marines were soon to found out on why, pretty quickly. When they took them with them to Guadalcanal. Where they performed miserably in combat.

What with a lot of jamming, problems with field stripping and cleaning. So they dumped them as quickly as they could. Then getting anything else that could shoot. That they could get their sticky fingers on.

Again nothing new here as any Marine will tell you after a few adult drinks.

Yes Bugs Bunny was in the Corp!

A Very Senior Marine NCO with both versions of the M-50. The shorter version was for the Paramarines with a folding wire stock.

The Paramarines were Marine Airborne Units. That the Marine Corp raised because of the Army’s 82nd & 101st Airborne Divisions publicity.

(They had a mixed reputation and were disbanded by the Corp near the end of WWII)

Here is some more information about the M50

M50 Reising

| Model 50 Reising | |

|---|---|

The Reising Model 50 submachine gun

|

|

| Type | Submachine gun |

| Place of origin | United States |

| Service history | |

| In service | 1941–1953 |

| Used by | See Users |

| Wars | World War II Hukbalahap Rebellion Malaysian Emergency[1] Costa Rican Civil War[1] |

| Production history | |

| Designer | Eugene Reising |

| Designed | 1940 |

| Manufacturer | Harrington & Richardson |

| Produced | 1941–1945 |

| Variants | M55, M60, M65 |

| Specifications | |

| Weight | 3.1 kg (6.83 lb) (M50) 2.8 kg (6.2 lb) (M55) |

| Length | 959 mm (37.8 in) 787 mm (31.0 in) stock retracted (M55) |

| Barrel length | 279 mm (11.0 in) (M50) |

|

|

|

| Cartridge | .45 ACP (M50 and M55)[2] .45 ACP (M60) .22 LR (M65) |

| Action | Delayed blowback, closed bolt |

| Rate of fire | 550 rounds/min (M50) 500 rounds/min (M55) |

| Muzzle velocity | 280 m/s (919 ft/s) |

| Maximum firing range | 300 yards |

| Feed system | 12- or 20-round detachable box magazine |

| Sights | Front blade, rear notch |

The .45 Reising submachine gun was manufactured by Harrington & Richardson (H&R) Arms Company in Worcester, Massachusetts, and was designed and patented by Eugene Reising in 1940. The three versions of the weapon were the Model 50, the folding stock Model 55, and the semiautomatic Model 60 rifle.[3] Over 100,000 Reisings were ordered during World War II, and were initially used by the United States Navy, Marine Corps, and the United States Coast Guard, though some were shipped to Canadian, Soviet, and other allied forces to fight the Axis powers.[4]

Contents

[hide]

History[edit]

A U.S. Coast Guard sailor on shore patrol with working dog and a Reising Model 50 with 12-round magazine.

The Reising submachine gun was a very innovative weapon for its time featuring firepower, accuracy, excellent balance, light weight and ease of manufacture compared to the Thompson Model 1928 submachine gun, the leading American competitor of the time. But poor combat performance of the Reising contrasted with favorable combat and law enforcement use of the Thompson forever mired the weapon in controversy.[3]

Eugene Reising was an excellent marksman and ordnance engineer who believed engineering principles must match actual field needs. Reising practiced his creed by being an avid shooter, and by serving in the early 1900s as an assistant to firearm inventor John M. Browning. In doing so, Reising contributed to the final design of the US .45 Colt M1911 pistol, one of the most reliable pistols in history. Reising then designed a number of commercial rifles and pistols on his own, when in 1938, he turned his attention to designing a submachine gun as threats of war rapidly grew in Europe.[3]

Two years later he submitted his completed design to the Harrington & Richardson Arms Company (H&R) in Worcester, Massachusetts. It was accepted, and in March 1941, H&R started manufacturing the Model 50 full stocked submachine gun. Months later, production began on the Model 55 (identical to the Model 50 other than having a folding wire buttstock, no compensator, and a barrel half an inch shorter); and the Model 60 full stocked semiautomatic rifle that also resembled a Model 50, but had a 7.75 inch longer barrel without cooling fins or compensator.[3]

H&R promoted the submachine guns for police and military use, and the Model 60 for security guards. After the Japanese attack on Pearl Harbor in December 1941 the US was suddenly in desperate need of thousands of modern automatic weapons. Since the Reising’s only competitor was the venerable .45 ACP Thompson Model 1928A1 submachine gun, a weapon that epitomized reliability and exquisite machining, the more easily manufactured Reising was quickly adopted by the US Navy and Marines as a limited-standard weapon.[3]

The US Army first tested the Reising in November 1941 at Fort Benning, Georgia, and found several parts failed due to poor construction. Once corrected a second test was made in 1942 at Aberdeen Proving Ground, Maryland. In that test 3,500 rounds were fired resulting in two malfunctions: one from the ammunition, the other from a bolt malfunction. As a result, the Army didn’t adopt the Reising, but the Navy and Marines did, faced with insufficient supply of Thompsons.[3]

The Navy and Marines also noticed that the Reising had certain advantages over the Thompson. It was less costly, costing $62 compared to the $200 for the Thompson. It was much lighter (seven vs. eleven pounds). And, the Model 55 was much more compact (about twenty-two vs. thirty-three inches in length)–the most compact, accurate, and lightest submachine gun in the world at the time.[3]

The Reising cost and weighed less than the Thompson because its metal components were mostly stampings instead of machined parts. Its low weight was due to its delayed blowback design, whereas most WWII-era submachine guns utilized the simple blowback principle. Simple blowback relies largely on the mass (weight) of the bolt to secure the cartridge when firing, and therefore requires this component to be particularly heavy. (The 1928A1 Thompson had a more involved Blish lock system, but this was similarly dependent on high bolt mass.) It was more balanced because the barrel-and-receiver-group rested concentrically within the stock. It had smoother lines because the stock was of conventional shape, and the cocking handle (action bar) was placed inside the forearm. In addition, it was more accurate because the closed-bolt only shifted the hammer and firing pin on firing, whereas the Thompson slammed home a heavy bolt and actuator.[3]

Design[edit]

Though described as a submachine gun, the Reising was designed as a compact lightweight semi-automatic delayed blowback carbine, firing from a closed bolt for accuracy. The Reising was made in selective fire versions that could be switched between semi-automatic or full-automatic fire as needed and in semi-auto only versions to be used for marksmanship training and police and guard use. The Reising had a designed full-auto cyclic rate of 450–600 rounds per minute but it was reported that the true full-auto rate was closer to 750–850 rounds per minute. At those rates, the twenty round magazine could be emptied in less than two seconds. In 1941, the Reising was priced at approximately $50 per weapon as opposed to $225 for the standard military issue Thompson submachine gun.[5]

Variants[edit]

There were four versions of the Reising, two selective fire models: the M50 and M55, and two semi-automatic only variants—the M60 a .45 ACP light rifle variant[6] and the M65 chambered for the .22 Long Rifle rimfire cartridge designed for training purposes.

There were two differences between the M50 and the M55, those being the elimination of the compensator and the addition of a folding wire buttstock making the M55 lighter and shorter. M55 was originally issued to Marine parachute infantry and armored vehicle crews.

The M60 was a long-barreled, semi-automatic carbine model designed primarily for military training and police use. However, few of these were ever sold. The Marines used M60s for training, guard duty, and other non-combat roles. Some M60s were believed to have been issued to Marine officers at Guadalcanal.[7] The remaining guns were passed on to State Guards and civilian law enforcement agencies.

USMC Deployment[edit]

The Reising entered military service primarily because of uncertainty of supply of sufficient quantities of the Thompson submachine gun. In the testing stage, it won out over some other competing designs. It was very light and quite accurate in aimed fire, and “capable of intensive fire against personnel within a range of 300 yards.”[8] This was attributed to its better stock fit and intricate closed bolt, delayed blowback design, though its firepower was somewhat limited due to the 20-round capacity of its largest magazine.[9][10] Most submachine guns fire from the open bolt position, meaning the full weight of the bolt slams forward when the trigger is pulled; with the Reising, only a lightweight firing pin striker moves when the trigger is pulled.[3]

The U.S. Marines adopted the Reising in 1941 with 4,200 authorized per division with approximately 500 authorized per each infantry regiment.[11][12] Most Reisings were originally issued to Marine officers and NCOs in lieu of a compact and light carbine, since the newly introduced M1 carbine was not yet being issued to the Marines. Although the Thompson submachine gun was available, this weapon frequently proved too heavy and bulky for jungle patrols, and initially it too was in short supply.[9]

During World War II, the Reising first saw action on August 7, 1942, exactly eight months to the day after Pearl Harbor, when 11,000 men from the 1st Marine Division stormed the beaches of Guadalcanal, in the Solomon Islands. This sweltering ninety-mile long mountainous island was covered with dense jungle and swamps, and was defended by Japanese troops. Since Guadalcanal had an airfield, the island had to be taken as Japanese aircraft from there could isolate Australia and New Zealand from America. To the Marines’ surprise, as they stepped off their landing craft and their naval fire crept forward, they were met not by the Japanese, but by silence and shattered coconut groves that fringed the beach. Advancing cautiously into the dark, musky jungle, they pushed forward and took the airfield the following day. But Japanese warships and reinforcements were en route. That night, powerful shell fire swept the Marines as they were suddenly cut off from sea; to be locked in mortal ground combat with the Japanese 35th Infantry Brigade, and 2nd and 28th Infantry Divisions.[3]

On the same date of Guadalcanal’s invasion, the Model 50 and 55 saw action by fast-striking, camouflage-dressed, 1st Marine Raiders on the small outlying islands of Tulagi and Tanambogo to the north. Two companies of Marine paratroopers, “The Devil Dogs,” dressed in olive drab jump smocks also used Model 55s to attack the island of Gavutu, between Tulagi and Tanambogo. Although Tulagi and Tanambogo were each secured in a day, the fighting was fierce. Japanese firing from caves and beach dugouts destroyed many of the raiders’ assault craft before touching shore. At day’s end, the raiders suffered 234 casualties from a 750-man force. The paratroopers fared worse. Of the 377 men who assaulted Gavutu, 212, roughly two-thirds were killed or seriously wounded, many because escorting warships couldn’t provide close fire support in the uncharted waters, and bombers sent to assist the paratroopers dropped their ordnance short killing their own men. Following six months of intense fighting, Guadalcanal fell to the Marines on February 7, 1943, at a cost of 6,000 wounded and killed Americans as well as 20,000 dead Japanese. Guadalcanal’s capture marked the beginning of the end of the Japanese Empire; other than minor advances in Burma and China, the Japanese were continuously pushed back to their homeland.[3]

Although Paramarines and armored crewmen had been issued the folding stock M55, the weapon’s poorly designed wire-framed stock tended to fold while firing and soon earned the M55 a poor reputation.[4] Moreover, the Reising was designed as a civilian police weapon and was not suited to the stresses of harsh battle conditions encountered in the Solomon Islands—namely, sand, saltwater and the difficulty in keeping the weapon clean enough to function properly. Tests at Aberdeen Proving Ground and Fort Benning Georgia had found difficulties in blindfold reassembly of the Reising, indicating the design was complicated and difficult to maintain. Many of the parts were hand fitted at the factory; this lack of parts interchangeability was not a problem for a civilian security or police firearm, but it was very problematic when Reisings were maintained in the field under combat conditions.[13]

While more accurate than the Thompson, particularly in semi-automatic mode, the Reising had a tendency to jam.[9] This was in part due to its overly complex delayed-blowback

The Reising earned a dismal reputation for reliability in the combat conditions of Guadalcanal.[14] Fortunately, the M1 carbine eventually became available and was often chosen over both the Reising and the Thompson in the wet tropical conditions, as the M1928 Thompson’s built-in oiling pads in the receiver were a liability.[15]

Withdrawal from the Fleet Marine Force[edit]

In late 1943 following numerous complaints, the Reising was withdrawn from Fleet Marine Force (FMF) units and assigned to Stateside guard detachments and ship detachments.[16] After the Marines proved reluctant to accept more Reisings, and with the increased issue of the .30-caliber M1 carbine, the U.S. government passed some Reising submachine guns to the OSS and to various foreign governments (as Lend-Lease aid). Canada

Many Reisings (particularly the semiautomatic M60 rifle) were issued to State Guards for guarding war plants, bridges, and other strategic resources. And after the war thousands of Reising Model 50 submachine guns were acquired by state, county, and local U.S. law enforcement agencies. In this role the weapon proved much more successful, and by doing so, forever mired the weapon in controversy.[3]

Issues of reliability[edit]

H&R was justifiably proud of the Reising’s superior accuracy and balance, lighter weight, and ease of manufacturing when compared to the Thompson. However, the Reising’s close tolerance and delicate magazine proved unreliable in the sand and mud of the Solomons—unless kept scrupulously clean. The gun quickly became despised by front-line Marines, and Lieutenant Colonel Merritt A. Edson, Commander, 1st Marine Raider Battalion, ordered that Reisings be flung into Guadalcanal’s crocodile infested Lunga River, as his troops resorted to reliable bolt-action Springfield rifles.[3]

This failure made a mockery of H&R’s company slogan, “Six-and-one-half pounds of controlled dynamite. The H&R Reising will get a bullet there when you need it!”[3]

There are other reasons for its failure. Foremost was the Reising’s complex design of many small pins, plungers, springs and levers. Disassembly and assembly was difficult even under normal conditions. Simple maintenance was problematic as there was no bolt hold-open device. Chambering a cartridge was awkward as the action bar was hard to grasp in the forearm and could be obstructed by the sling. Worse, the safety/selector switch couldn’t be sensed by feel at night if it was in the safe, semi, or automatic position.[3]

“Filing-to-fit” of certain parts during production limited interchangeability. The exposed rear sight had no protective ears and was vulnerable to breakage. The adjustable front sight could be lost if the retaining screw wasn’t tightly secured. The weapon was susceptible to jamming if grime clogged the bolt’s locking recess in the receiver. The two small magazine guide retaining pins and corresponding receiver stud holes were tapered allowing disassembly and assembly only from one direction—right to left for disassembly, and left to right for assembly; adding unacceptable levels of complexity in a combat environment. The retaining pins had to be delicately pounded out whenever the bolt needed to be removed for cleaning. During the reassembly process, if the retaining pins were inserted too much or too little when reassembling, the receiver might not fit back into the tight confines of the stock.[3]

Model confusion[edit]

What constitutes a “commercial” and “military” Model 50 is amorphous. First, H&R never made a distinction; the distinction is made by collectors. This confusion stems from a period in production where early Model 50s were manufactured with commercial characteristics and H&R’s wartime practice of randomly installing old parts in stock throughout production.[3]

While there is not one factor that distinguishes the so-called commercial from the military model, the commercial model is usually blued. It commonly has a fixed front sight and a rear sight with no retaining screw. It often has 28 fins on the barrel, a one piece magazine release, no outward flanges on the safety/selector switch, and no sling swivels. Lastly, the commercial model commonly has a smooth take-down screw, a two-hole trigger guard, and serial numbers ranging from one to 20,000.[3]

Military Reisings are usually parkerized. They often have an adjustable front sight with an Allen screw and a rear sight with a retaining screw. They routinely have 14 fins on the barrel, a two piece magazine release, outward flanges on the safety/selector switch, sling swivels, stock ties (crossbolts through the forearm), and a knurled take-down screw. Finally, the military model commonly has a three-hole trigger guard, proofmarks like “PH” or “Pm2” above the chamber, and serial numbers ranging from 20,000 to 120,000.[3]

There are three types of H&R magazines. The first and second models are both smooth body, are blued, and are twenty-shot double column. The first model is distinguished by five cartridge peep holes on the left side, a feature eliminated on the second model to prevent mud and sand from entering. In contrast, the third model is parkerized, has two long indentations on the sides to reduce its capacity to a twelve-shot single column magazine because of feeding problems experienced with former models.[3]

Post World War II[edit]

Production of the Model 50 and 55 submachine guns ceased in 1945 at the end of World War II. Nearly 120,000 submachine guns were made of which two thirds went to the Marines. H&R continued production of the Model 60 semiautomatic rifle in hopes of domestic sales, but with little demand, production of the Model 60 stopped in 1949 with over 3,000 manufactured. H&R sold their remaining inventory of submachine guns to police and correctional agencies across America who were interested in the Reising’s selective-fire capability, semi-auto accuracy, and low cost relative to a Thompson. Then faced with continued demand, H&R resumed production of the Model 50 in 1950 which sputtered to a halt in 1957 with nearly 5,500 additional submachine guns manufactured. But just when the Reising story seemed to end, a foreign order was received in the 1960s for nearly 2,000 more Model 60s, but that order was finally the end.[3]

Decades later, in 1986, H&R closed their doors and the Numrich Arms (aka Gun Parts Corporation) purchased their entire inventory. Acquiring a number of Model 50 receivers, Numrich assembled them with parts. These weapons all have an “S” preceding the serial number and were sold domestically in the early 1990s after reparkerization and fitting with newly manufactured walnut stocks. These stocks are distinguished from originals by their wider than normal sling swivels and buttstocks, by the fact they have no stock ties, and have H&R marked plastic buttplates (originals were unmarked metal).[3]

Machine gun murders[edit]

In New Zealand in December 1963, two men thought to have been operating an illegal beerhouse business were murdered execution-style with a Reising machine gun. Machine guns were a type of weapon thought not to exist in the country at the time.[18]

Users[edit]

Argentina[1]

Argentina[1] Australia[1]

Australia[1] Brazil[1]

Brazil[1] Canada[1]

Canada[1] Costa Rica[1]

Costa Rica[1] French Indochina: 4,000 ordered, delivery and issue not confirmed.[1]

French Indochina: 4,000 ordered, delivery and issue not confirmed.[1] Finland: Captured from the Red Army.[1]

Finland: Captured from the Red Army.[1] Mexico[1]

Mexico[1] Nazi Germany: Captured from the Red Army.[1]

Nazi Germany: Captured from the Red Army.[1] New Zealand[1]

New Zealand[1] Soviet Union: Received in the form of Lend-Lease aid.[1]

Soviet Union: Received in the form of Lend-Lease aid.[1] Philippines: Used by the Philippine Army and Philippine Constabulary during World War II and into the 1960s.

Philippines: Used by the Philippine Army and Philippine Constabulary during World War II and into the 1960s. United States[1]

United States[1] United Kingdom[1]

United Kingdom[1] Uruguay[1]

Uruguay[1] Venezuela[1]

Venezuela[1]

**Warning Crude GI Humor Below!**

* I was once told by a Vietnam War Marine friend of mine. Who use to strap a M-60 Tank on his back up in I Corp.

What a REAL Marine actually is. It is a Green Amphibious Monster. That lives on three kinds of shit (Horse, Chicken and Bullshit) Who also has the spirit of the Waffen SS and the weapons of the Italians. I really do believe that he was steel on target about that one.

Terminal Lance

I think that only my Brother In Law is the only Marine in our family. But none the less I really like this Comic Strip about today’s Marine Corp. It seems that they have a lot of the same issues that the US Army has also.

I think that only my Brother In Law is the only Marine in our family. But none the less I really like this Comic Strip about today’s Marine Corp. It seems that they have a lot of the same issues that the US Army has also.

Also the Author is whip smart also. So hopefully some of your guys might like it also!

The German MP40 Versus the American M3A1 Grease Gun

Teutonic Refinement Meet Yankee Brown

World War II changed most everything about planet earth. Society, culture, industry, and politics all underwent a seismic shift during this worldwide conflict that ultimately claimed 50 million souls. This most horrible of wars spilt rivers of blood.

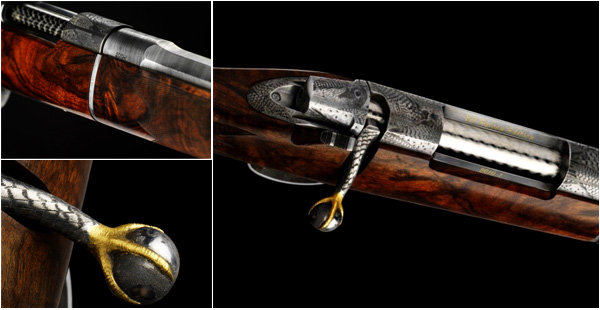

Previously gunmaking retained some modicum of art. Military weapons combined the machinist’s touch with the woodworker’s skill to produce weapons that were elegant, graceful, and expensive. Receivers typically began life as huge chunks of forged steel before being cut or turned into something mechanically complex, sometimes on machines still driven by steam. In the desperate fight for national survival that defined World War II, however, man perfected the mass production of his implements of destruction.

MP40 M3A1 Grease Gun

- Weight. 8.75 lbs 7.95 lbs

- Length—Stock Extended 32.8 in 29.8 in

- Length—Stock Retracted 24.8 22.8 in

- Barrel Length 9.9 in 8 in

- Cartridge 9mm .45 ACP

- Muzzle velocity 1,300 feet/second 920 feet/second

- Rate of Fire 500 rounds/minute 450 rounds/minute

- Sights Fixed Fixed

- Total wartime Production 1.1 million 700,000

German Origins

The MP38 was cut from a heavy steel tube and can be readily identified by the longitudinal grooves cut in the receiver. The MP38 also has a dime-sized lightening hole stamped into both sides of the magazine well. Otherwise, the MP38 incorporated stamped steel fire controls, sights, and ancillary widgets. The gun also eschewed the use of wood anywhere in its production.

The MP38 was cut from a heavy steel tube and can be readily identified by the longitudinal grooves cut in the receiver. The MP38 also has a dime-sized lightening hole stamped into both sides of the magazine well. Otherwise, the MP38 incorporated stamped steel fire controls, sights, and ancillary widgets. The gun also eschewed the use of wood anywhere in its production.

The MP38 was initially intended for use within and around armored vehicles. As a result, a synthetic polymer barrel rest was included underneath the barrel. The hook on the end of the rest was designed to rest outside the armor of a halftrack such that the muzzle didn’t inadvertently wander into the crew compartment under recoil.

The German MP40 submachine gun ushered in an entirely new era in military gun building. Sporting stamped steel components and a collapsible stock, the MP40 was the world’s first martial weapon truly optimized for mass production.

The MP38 rendered superb service in the hands of German Fallschirmjagers during their parachute assaults into Norway, Poland and Belgium. This tidy little submachine gun also armed German Panzer troops on their Blitzkrieg across Europe early in the war. Despite its incorporation of advanced production techniques, the Germans still saw room for improvement.

The MP40

The primary difference between the MP38 and the subsequent MP40 rested in the production of the receiver. The receiver of the MP40 was pressed out of thin gauge sheet steel on industrial presses. As a result, the gun could be produced en masse by semi-skilled labor. Production of the MP40 continued until the MP44 assault rifle supplanted it. Around 1.1 million of these guns were ultimately produced.

The folding steel stock on the MP40 was a bit flimsy yet remained effective under hard use. The pivoting buttplate must be folded flat when stowed.

The MP40 fed from a double column 32-round box magazine that tapered to a single feed for presentation. While offering reliable feed geometry, this design was prone to stoppage when dirty and required a magazine loading tool to load. The gun also incorporated a unique recoil assembly wherein nested steel cups telescoped into themselves around the recoil spring. This gave the MP40 an unusually smooth firing cycle. When combined with the weapon’s sedate rate of fire and front-heavy design this made the gun imminently controllable. The weapon was fully automatic only.

The original MP38 and early MP40s lacked a manual safety beyond a cutout to lock the bolt to the rear. However, the gun could be dropped onto its butt with a loaded magazine in place and suffer an accidental discharge. In this circumstance, the bolt might drop back far enough to pick up a round but not far enough to engage the sear. The fix for this problem involved cutting a locking slot in the front of the receiver and replacing the bolt with an improved version. The new charging handle could be snapped in place to secure the bolt in the forward position. Until the fix could be updated the Germans issued a special leather strap that would lock the bolt in place externally.

The Nazis serialized everything on their weapons to include the firing pin and these early Bakelite grip plates.

Despite the streamlined nature of the MP40 the Germans just couldn’t bring themselves to let go of their compulsive gunmaking proclivities. As a result, the MP40 is simply festooned with waffenamt acceptance stamps and every part big enough to accept one sports a serial number, to include the firing pin. This does indeed make for an elegant firearm that likely inspired confidence in its users, but did not lend itself to mass production by an industry threatened both day and night by Allied bombing. The MP40 has been encountered in action as recently as the Syrian Civil War.

The American Buzzgun

The American M3A1 Grease Gun was as utilitarian as we could make it. Sporting stamped steel for most of its components, the Grease Gun was ultimately a remarkably effective service weapon.

World War II was a come-as-you-are affair for the United States, and we found ourselves woefully unprepared when Pearl Harbor finally dragged us kicking and screaming into war. Our issue submachine gun of the day was the 1928A1 Thompson, but it was obsolete before the first bomb fell on that fateful Sunday morning. However, we Americans are a hearty lot and we responded by doing what we do best. We banded together, rolled up our sleeves, and built stuff.

The M1928 morphed into the somewhat simplified M1A1 Thompson that was a bit easier and cheaper to build. Around 1.5 million Tommy guns rolled off the lines during the war to equip Allied forces of all nationalities. Even while we were ramping up to build Thompsons by the hundreds of thousands the War Department was rushing to secure a low-cost replacement.

The Thompson was sinfully heavy. With a loaded 50-round drum in place it weighed nearly what a Browning Automatic Rifle (BAR) might. It was also mechanically complicated and suffered simply dreadful ergonomics. Despite its shortcomings, however, American GIs loved the gun. Many to most of them had cut their teeth on Saturday afternoon crime serials and going to war with a gangster chopper held an allure. The replacement for the Thompson was as unlike this big pre-war gun as might possibly be imagined.

The Grease Gun

The M3 Grease Gun was first adopted for service just over a year after the Pearl Harbor attack. In stark contrast to the Thompson, the M3 was simple, ugly, and utilitarian. The receiver was comprised of two halves of sheet steel welded together to form a shell. The bolt rode loosely within this assembly on a pair of guide rods. This allowed the gun to function in the face of modest damage. The sliding stock was formed from heavy gauge steel wire. In the original M3 version a ratcheting lever on the right side of the gun actuated the bolt. Everything that could be produced via industrial stampings was produced via industrial stampings. When compared to the elegant and meticulously built Thompson the M3 was positively homely.

The charging handle of the M3 was found to be unduly flimsy and the unfenced magazine release allowed the magazine to be dropped inadvertently. As a result, the improved M3A1 added a raised steel fence around the magazine release and dispensed with the ratcheting charging handle entirely. In its place was a simple divot in the bolt that allowed the operator to retract the bolt with a standard finger.

The Grease Gun weighed around 8 pounds and fed from the same sort of double column, single feed magazine that drove the MP40. In the M3A1 version the wire stock incorporated a useful and effective magazine loading tool. A large stamped steel dust cover folded in place to occlude battlefield grunge. A steel tab on this appendage locked the bolt and served as the gun’s sole safety. The gun’s heavy bolt and long travel conspired to yield a rate of fire of around 450 rounds per minute.

The trigger and receiver-cum-pistol grip were all formed from stamped steel. The trigger guard was a simple length of spring steel.

The Grease Gun cost $15 to make in 1943 (around $215 today) and was quite literally disposable. The Army supply system did not stock spare parts. When a Grease Gun went down it was discarded. There was a field modification of early M3 models that involved milling a slot in the receiver for a steel charging handle that reciprocated with the bolt for use when the ratchet system failed.

The first recorded combat use of the Grease Gun was on the Airborne drop in support of D-Day. While GIs distrusted the Greaser early on for its crude appearance, most ultimately expressed grudging admiration for the design. The gun was profoundly robust and thoroughly reliable. The improved M3A1 version briefly saw action in the closing weeks of the war. The Grease Gun was used through the Korean War and Vietnam War all the way up to the Gulf War. I encountered high mileage World War II-vintage M3A1 Grease Guns in the hands of U.S. Army tankers while I was on active duty in the 1990s.

Face Off

Both these guns are bulky. The left-sided nature of the charging handle on the MP40 means the sling must be arranged on the right. This makes the gun a bit more awkward to tote. The Grease Gun uses a standard canvas M1 Carbine sling, while the MP40 employs an adjustable leather version. The MP40 sights are flip adjustable for 100 and 200 meters while the Grease Gun’s are simply fixed, but they are comparably effective.

The two guns sport very different personalities, but I found that I could keep my rounds on target with a comparable facility with both guns. The big .45ACP bullets are fully twice as heavy as the 9mm rounds the MP40 fires, so they bring markedly more horsepower. Both weapons enjoy a sedate rate of fire so singles and doubles are easy with a disciplined trigger finger.

The MP40 and the M3A1 Grease Gun were birthed under utterly different circumstances. One nation wanted to enslave the world. The other wanted to free it. That these guns share so many similar morphological characteristics is intriguing. These days rifle-caliber carbines have displaced the submachine gun in the arsenals of most developed countries. However, for a time, these two stamped steel submachine guns slugged it out to determine the mastery of the world.

For more information about period gear used as support in this article, click here.

NSFW

Something that will be easy on a man’s eyes

Enjoy

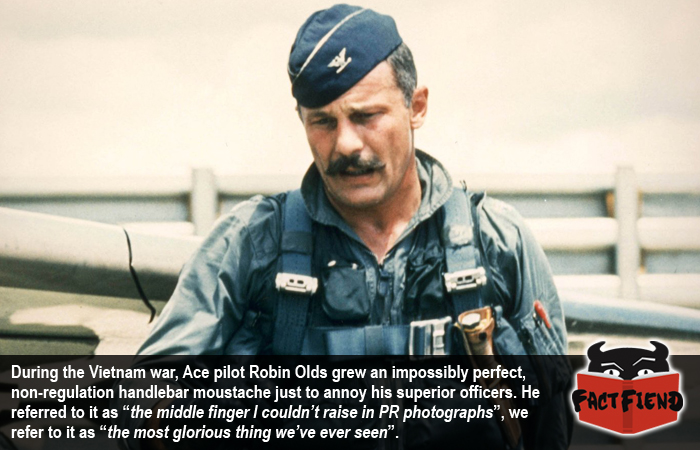

The Mustache Story

The Mustache

Reprinted without his permission.

It happened in a galaxy far away and long ago. The galaxy was South Vietnam and the time was 1970. I was a Specialist 4 trying, not completely successfully, to adjust to the military ambience. Or in the technical language of the military, I was an asshole with an attitude. And an enormous mustache.

Now you might think that in an extraordinarily hot and humid tropic country, a mustache would be the very last thing one would want to grow on one’s face. And ordinarily you would be correct. However, the army is very much like being in high school; whatever they say you cannot do, is exactly what you desire most to do. And when an army seeks order by intricate regulation, it summons from the depths of hell a legion of barracks lawyers.

In the midst of war, out near the sharp and pointy end, such niceties as the minutiae of personal grooming are usually overlooked. But I had been reassigned to finish the last part of my tour of duty in the battalion motor pool. The motor sergeant was one Sergeant Jach, a man who seems to have excelled at being a Tech Sergeant, since he had been promoted to that rank repeatedly, and showed no sign that he ever intended to advance to First Sergeant. His primary talents were yelling, verbal abuse, and throwing around his rank, skills highly valued in his current position. Oh, and selective enforcement of petty regulations.

Which brings us back to … The mustache. It had already left behind the Teddy Roosevelt stage and had reached Stalinesque proportions, and showed every sign of aspiring to a truly Nietzchean dimension. And I was happy. And then one day, the mustache was noticed by Sergeant Jach.

“Specialist! That fucking mustache isn’t regulation. Get it trimmed or get rid of it by noon formation. That’s an order!” And he quoted me the regulation standard, a military mustache could not extend beyond the ends of one’s lips, nor touch the nose, nor touch the top of one’s upper lip – essentially a David Niven mustache.

In such a circumstance, there is only one thing a troop can do. And after lunch, before formation, I bade my mustache farewell, and trimmed it. But strangely this did not satisfy Sergeant Jach.

As we stood in formation and were called to order, his eye fell upon me….

“Wha…! What! What? What…the fuck!!!?” Perhaps for the first time in his career, even obscenities failed him. “Specialist. What’s that on your face?”

“My mustache, sergeant. Trimmed to regulation, just like you ordered.”

“But … Its only on the right side of your face!”

“Yes sergeant. Nothing in the regs says it has to be symmetrical.”

“But you look like a fucking O.D. clown.”

“Yes Sergeant. I’m even wearing an O.D. baggy suit.”

“Do you wanna look like an idiot?!”

“I don’t mind. Nobody around here I want to impress.”

And so it went back and forth for about ten minutes, the raging storm and the calm, immovable boulder. Eventually, we reached a negotiated settlement of truly Kissingerian elegance. Sergeant Jach agreed that I had a right under army regulations to wear a mustache on only half my face, and I agreed that, having made my point, I didn’t really want to spend the rest of my military career looking like a clown. And the remainder of the mustache was shaved off. And for the rest of my tour, Sergeant Jach never jached me around again.

****************************************

My Opinion. Not that it matters or anybody cares about it!

As you can see below. The Military has had a very long relationship with facial hair. As to myself. I say if it helps a man fight harder and better. Then let it come forth!

Mannlicher M1901

This a very strange and frankly ugly at least for me pistol. I have only see it once. When I was much younger.

It seemed to work for the owner and he had a fairly good pattern with it. But I was told that it is extremely hard to find ammo for it now a days. Frankly I was NOt impressed by it then or now.

Here is some more information below about this false start of a Semi Auto Pistol.

I hope that you like this.

Thanks

Grumpy

Mannlicher M1901

| Mannlicher M1901 | |

|---|---|

|

|

| Type | Semi-Automatic Pistol |

| Place of origin | Austria-Hungary |

| Service history | |

| Used by | See Users |

| Wars | World War I |

| Production history | |

| Designer | Ferdinand Mannlicher |

| Manufacturer | Steyr-Mannlicher |

| Produced | 1901–1903 |

| No. built | 4,000 |

| Variants | Mannlicher M1905 |

| Specifications | |

| Cartridge | 7.63mm Mannlicher |

| Action | Delayed blowback |

| Muzzle velocity | 1070 ft/s (326 m/s) |

| Feed system | 8 round stripper clip into magazine |

| Sights | Iron sights |

The M1901 Mannlicher Self-Loading, Semi-Automatic Pistol was an early semi-automatic pistol design.[1]

Contents

[hide]

General features[edit]

This pistol is one of the most simple of blow-back semi-automatic pis

According to the Steyr factory records this arm, patented in 1898, was originally introduced as the “Model 1900” and used a special 8 mm cartridge.

When introduced commercially in 1901 it was chambered for a special straight-case cartridge listed in Austria as “7.63 mm Mannlicher”, designated in Germany as “7.65 mm Mannlicher” (Note: There is also another 7.65 mm Mannlincher cartridge, M.1903, similar to 7.65 mm Borchard), and described in the U.S. as “7.65 x 21 mm”. The Mannlicher “straight sided” cartridge actually has a straight taper to help in extraction.

The cartridge for this pistol was manufactured in Europe until the beginning of WWII. The cartridge has a bullet weighing approx. 85 grains (5.5 g) which may be steel or cupro-nickel jacketed. The powder charge varies with the type of powder used, the European standard being about 3.5 grains (227 mg) of DWM standard powder, producing a muzzle velocity in the neighborhood of 1070 ft/s (326 m/s).

While this is a cartridge of considerable power to use in a blow-back action, the pistol design itself is so sturdy that the arm has given satisfaction through the years.

The firing chamber in this design is part of the receiver proper. The magazine is housed in the grip and is loaded with a clip through the top of the open action. Because of the extremely simple lock work employed, the pistol has a minimum bulk for an arm of its type.[1]

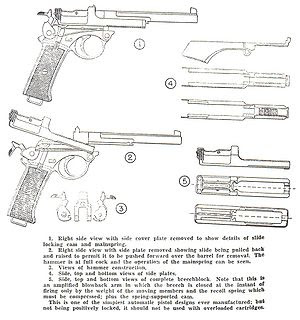

Breechblock design[edit]

The moving breechblock of this pistol was designed as a slide with two rails extending forward beneath the stationary receiver/barrel where they are connected by a cross beam which is also part of the single breechblock forging. The barrelis screwed into the chamber section of the receiver and has a front sight top rib which is part of the barrel forging.

A spiral recoil spring is positioned horizontally, directly below the barrel between the parallel guides of the receiver and rails of the breechblock. An illustration of this spring is shown in the drawing from page 216, Mannlicher Rifles and Pistols, Smith, 1947. When the pistol is discharged, as the breechblock moves to the rear and the slide rails travel back in the receiver guides, the cross-beam at the forward end serves to compress the recoil spring against the frame.

The lockwork is incorporated on the left side of the frame where it is covered by a removable side cover housing of unusual design, being wrapped around at the forward end and serving also as a cover of the recoil spring. An illustration of this cover is shown in the drawing from page 218,.[2] This cover is installed on the frame from the front and is retained buy a spring catch forward of the trigger-guard.

The trigger is connected on the left side of the frame to a trigger bar which, as the trigger is pulled, moves rearward pushing against the sear tail which is under the control of the V-spring that serves as both trigger and sear springs. The sear nose engages in a notch in the left fork of the hammer (the hammer is external) to provide a fine trigger pull which is very unusual in an automatic pistol.

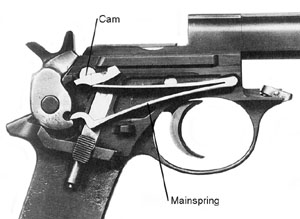

Mounted on the frame under the right portion of the side cover housing is the mainspring, a heavy V-spring. Its greater arm (lower) engages a notch in the right fork of the hammer to drive it forward when released by the sear. Its lesser arm (upper) continuously presses a cam upward that engages a slot in the under surface of the breechblock slide when the action is closed.[1]

To load the pistol grasp the breechblock on the serrated gripping surfaces on the sides and pull the machine straight to the rear. The magazine follower rises to hold the action open while the cross beam at the forward end of the slide compresses the recoil spring. Insert a loaded stripper clip into the clip guide in the face of the breech block and then strip the cartridges into the magazine, compressing the spring below the follower. An illustration of this process is shown in the drawing from page 214, Mannlicher Rifles and Pistols, Smith, 1947. The spring lip at the top of the magazine serves to hold the cartridges. The cam on the right side of the frame, being forced up by the lesser arm of the mainspring, pushes the cam into the slot in the under surface of the breechblock slide and holds the machine back as explained above.[1]

Because of this cam hold-open, the pistol does not close when the clip is removed. However, drawing back slightly on the breechblock will ride it over the cam, and releasing it will permit the recoil spring to close the action.

As the breechblock goes forward, the extractor mounted in the top of the block will snap over the extracting groove of the cartridge as it is chambered.[1]

Discharging

Movement of the trigger linked to the trigger bar releases the sear from the hammer notch. The compressed arm of the mainspring, pushes against the hammer notch, rotating the hammer on its axis to strike the firing pin, discharging the cartridge.

The breechblock starts back at the instant of discharge, carrying the empty cartridge case with assistance of the extractor. The empty cartridge case is brought sharply against the ejector which is a bar at the back of the magazine. The underside of the breechblock is slotted to travel over the ejector.

The recoiling slide riding over the hammer causes the hammer to rotate on its axis, locking the sear in the notch of the left hammer fork.

The magazine spring forces the next cartridge up into line. At the apex of the recoil stroke the recoil spring acts to reverse the direction of the breechblock, chambering a fresh cartridge. Until trigger pressure is released another discharge is not possible.

Magazine unload lever

A unique feature of this pistol model is the unloading device. While the breechblock is held open, pulling down on the serrated lever on the right side at the top of the grip panel will withdraw the lip which is holding the cartridges in the magazine, enabling the magazine spring to move the platform up and force all the cartridges out of the magazine.

Users[edit]

Argentina: As “Modelo 1905”.

Argentina: As “Modelo 1905”. Austria-Hungary: Was purchased privately by many officers of the Austro-Hungarian army, though rejected officially after trials in 1904-5.

Austria-Hungary: Was purchased privately by many officers of the Austro-Hungarian army, though rejected officially after trials in 1904-5.

If and when I win the Lottery or something. This is what I am going right out & buy. That if it is still legal to so. So here is my list of what I would buy 1st. If you have a better idea post a response below.

Grumpy

Ohio ordnance BAR Semi Automatic Rifle