If and when I win the Lottery or something. This is what I am going right out & buy. That if it is still legal to so. So here is my list of what I would buy 1st. If you have a better idea post a response below.

Grumpy

Ohio ordnance BAR Semi Automatic Rifle

Author: Grumpy

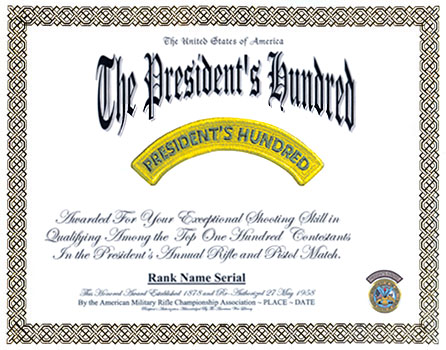

The Presidents 100

Now a lot of folks out there in the shooting community. Have never probably even heard of this program. I myself have never even seen one of these folks. They are that elite!

Who ever can legally wear all of these patches. Will qualify as a REAL BADASS in my book. That and the eye hand coordination of these folks must be off the scale!

Who ever can legally wear all of these patches. Will qualify as a REAL BADASS in my book. That and the eye hand coordination of these folks must be off the scale!

But enough said of that. As it usually happens. This very good idea found a serious patron in the form of Theodore Roosevelt. Who really got things rolling.

Hopefully one day I can go and at least see at Camp Perry Ohio. (By the way, it is a really nice place and the CMP program is a real hidden gem)

Thanks for your time that you spent reading this!

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

By the way the Paypal Button is still working! Yes I am still deep down a complete & total mercenary!

Here is also some more information about these incredibly skilled Folks!

The President’s Hundred Tab is currently one of four permanent individual tabs authorized for wear by the U.S. Army.[2]

History[edit]

The National Rifle Association‘s (NRA) President’s Match was instituted at the NRA matches of 1878, as the American Military Rifle Championship Match. It was patterned after an event for British Volunteers called The Queen’s Match, a competition started by Queen Victoria and initiated by the National Rifle Association of Great Britain in 1860, in order to increase the ability of Britain’s marksmen following the Crimean War.[1][5][10]

In 1884, the name was changed to the President’s Match for the Military Rifle Championship of the United States. It was fired at Creedmoor, New York until 1891. In 1895, it was reintroduced at Sea Girt, New Jersey.[1][5]

The tradition of making a letter from the President of the United States the first prize began in 1904 when President Theodore Roosevelt, at the conclusion of the President’s Match, personally wrote a letter of congratulations to the winner, Private Howard Gensch of the 1st Regiment of Infantry of the New Jersey National Guard.[1][5]

It cannot be ascertained as to when the President’s Match was discontinued; however, it is known that it was not fired during World Wars I and II. It appears to have disappeared during the 1930s and during the Depression when lack of funds severely curtailed the holding of matches of importance.[1][5]

The President’s Match was reinstated in 1957 at the National Matches as “The President’s Hundred.” The 100 top-scoring competitors in the President’s Match were singled out for special recognition in a retreat ceremony in which they passed in review before the winner and former winners of this historic match.[1][5]

On 27 May 1958, the NRA requested the Deputy Chief of Staff for Personnel’s approval of a tab for presentation to each member of the “President’s Hundred.” NRA’s plan was to award the cloth tab together with a metal brassard during the 1958 National Matches. The cloth tab was of high level interest and approved for wear on the uniform on 3 March 1958. The first awards were made at Camp Perry, Ohio, in early September 1958. Only the U.S. Navy has authorized the wear of the metal brassard on the uniforms of enlisted sailors. However, the NRA issued the metal brassard to all military and civilian personnel for wear on the shooting jacket.[1][5][10]

In 1977, the National Board for the Promotion of Rifle Practice (NBPRP) assumed responsibility for the President’s Match from the NRA. Today the CMP manages and awards the President’s Hundred Tab/Brassard to the top 100 shooters in those matches.[5]

In September 2008, the Department of the Army authorized a miniature metal tab to be worn on the new Army Service Uniform. This is a scaled-down replica of the President’s Hundred full-color embroidered tab.[1][7]

In January 2014, the Department of the Air Force, via an update to Air Force Instruction 36-2903, authorized the wear of the President’s Hundred Tab on the Airman Battle Uniform (olive drab version) and the Air Force service uniform(miniature full color replica) through the authorization for Airmen to wear any military badge they have earned given it is worn within uniform regulations.[6][7][11] [12]

See also[edit]

The Sig Saur in 40 S&W

As you have no doubt guessed by now. I up and bought myself a new toy. So I thought that I would share my experiences with it so far.

Now for a while now I wanted another Sig in 9mm. Since my P-220 in 45 ACP was getting very lonely.

So I went shopping and found out this. That here in the People’s Republic of California. It is easier to find a Trump Supporter in San Francisco. Than it is to find a P-226 in 9mm at a reasonable price. Surprised huh?

Therefore I had to “settle” for one in 40 S&W. (Life can be so hard at times!)

Anyways here is what I found out at the local noise pollution arena. (The Pistol Range)

Like the other Sig that I have. It is very well designed & built. It is also almost boring as to how accurate it is. Once you figure out where the piece throws its bullet.

This pretty close to what my pattern looked like at 20 feet. Honest!

Now about the 40 S&W Round itself.

I found that the round itself basically is a lot like the 45 ACP round. While the recoil was pretty much the same. As was the report too.

Since it was a Sig. I really can not say anything about accuracy. As up to now. I have not either seen or shot one that was not boringly accurate. Also I have never had one jam on me either.

But the big problem for me with this round are two fold. As the ammo is not cheap out here! That and sometimes it is very hard to find also.

So I am now seriously debating on if I am going to keep it or not. Time will tell, I guess!

Comparison of the 40 to other defensive rounds

here is some more videos, technical & other Information below!

Thanks for reading this!

Grumpy

.40 S&W

| .40 S&W | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

An expanded hollow point bullet (left) and an unfired hollow point .40 S&W cartridge

|

||||||||||||||||||||||||

| Type | Pistol | |||||||||||||||||||||||

| Place of origin | United States | |||||||||||||||||||||||

| Production history | ||||||||||||||||||||||||

| Designer | Bob Klunk | |||||||||||||||||||||||

| Designed | January 17, 1990 | |||||||||||||||||||||||

| Produced | 1990–present | |||||||||||||||||||||||

| Specifications | ||||||||||||||||||||||||

| Parent case | 10mm Auto | |||||||||||||||||||||||

| Case type | Rimless, Straight | |||||||||||||||||||||||

| Bullet diameter | .400 in (10.2 mm) | |||||||||||||||||||||||

| Neck diameter | .423 in (10.7 mm) | |||||||||||||||||||||||

| Base diameter | .424 in (10.8 mm) | |||||||||||||||||||||||

| Rim diameter | .424 in (10.8 mm) | |||||||||||||||||||||||

| Rim thickness | .055 in (1.4 mm) | |||||||||||||||||||||||

| Case length | .850 in (21.6 mm) | |||||||||||||||||||||||

| Overall length | 1.135 in (28.8 mm) | |||||||||||||||||||||||

| Case capacity | 19.3 gr H2O (1.25 cm3) | |||||||||||||||||||||||

| Rifling twist | 1 in 16 in. (406 mm) | |||||||||||||||||||||||

| Primer type | Small pistol | |||||||||||||||||||||||

| Maximum pressure | 35,000 psi (240 MPa) | |||||||||||||||||||||||

| Ballistic performance | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

| Test barrel length: 4 inches (100 mm) Source(s): [1][2] |

||||||||||||||||||||||||

The .40 S&W (10×22mm Smith & Wesson in unofficial metric notation) is a rimless pistol cartridge developed jointly by major American firearms manufacturers Smith & Wesson and Winchester.[3] The .40 S&W was developed from the ground up as a law enforcement cartridge designed to duplicate performance of the Federal Bureau of Investigation‘s (FBI) reduced-velocity 10mm Autocartridge which could be retrofitted into medium-frame (9mm size) semi-automatic handguns. It uses 0.40-inch (10 mm) diameter bullets ranging in weight from 105 to 200 grains (6.8 to 13.0 g).[4]

Contents

[hide]

History[edit]

In the aftermath of the 1986 FBI Miami shootout, in which two FBI special agents were killed and five wounded, the FBI started the process of testing 9×19mm Parabellum and .45 ACP ammunition in preparation to replace its standard-issue revolver with a semi-automatic pistol. The semi-automatic pistol offered two advantages over the revolver: 1) increased ammunition capacity and 2) increased ease of reloading during a firefight. The FBI was satisfied with the performance of its .38 Special +P 158 gr (10.2 g) L.S.W.C.H.P. (lead semi-wadcutter hollowpoint) cartridge (“FBI Load”) based on decades of dependable performance. Ammunition for the new semi-automatic pistol had to deliver terminal performance equal or superior to the .38 Special FBI Load. The FBI developed a series of practically oriented tests involving eight test events that they believed reasonably represented the kinds of situations that FBI agents commonly encounter in shooting incidents.[citation needed]

During tests of the 9×19mm and .45 ACP ammunition, the FBI Firearms Training Unit’s Special Agent-in-Charge John Hall decided to include tests of the 10mm cartridge, supplying his personally owned Colt Delta Elite 10mm semi-automatic, and personally handloaded ammunition. The FBI’s tests revealed that a 170–180 gr (11.0–11.7 g) JHP 10mm bullet, propelled between 900–1,000 ft/s (270–300 m/s), achieved desired terminal performance without the heavy recoil associated with conventional 10mm ammunition (1,300–1,400 ft/s (400–430 m/s)). The FBI contacted Smith & Wesson and requested it to design a handgun to FBI specifications, based on the existing large-frame S&W Model 4506 .45 ACP handgun, that would reliably function with the FBI’s reduced-velocity 10mm ammunition. During this collaboration with the FBI, S&W realized that downsizing the 10mm full power to meet the FBI medium velocity specification meant less powder and more airspace in the case. They found that by removing the airspace they could shorten the 10mm case enough to fit within their medium-frame 9mm handguns and load it with a 180 gr (11.7 g) JHP bullet to produce ballistic performance identical to the FBI’s reduced-velocity 10mm cartridge. S&W then teamed with Winchester to produce a new cartridge, the .40 S&W. It uses a small pistol primerwhereas the 10mm cartridge uses a large pistol primer.

The .40 S&W cartridge debuted January 17, 1990, along with the new Smith & Wesson Model 4006 pistol, although it was several months before the pistols were available for purchase. Austrian manufacturer Glock Ges.m.b.H. beat Smith & Wesson to the dealer shelves in 1990, with pistols chambered in .40 S&W (the Glock 22 and Glock 23) which were announced a week before the 4006.[5] Glock’s rapid introduction was aided by its engineering of a pistol chambered in 10mm Auto, the Glock 20, only a short time earlier. Since the .40 S&W uses the same bore diameter and case head as the 10mm Auto, it was merely a matter of adapting the 10mm design to the shorter 9×19mm Parabellum frames. The new guns and ammunition were an immediate success.[6][7]

The .40 S&W case length and overall cartridge length are shortened, but other dimensions except case web and wall thickness remain identical to the 10mm Auto. Both cartridges headspace on the mouth of the case. Thus in a semi-auto they are not interchangeable. Fired from a 10mm semi-auto, the .40 Smith & Wesson cartridge will headspace on the extractor and the bullet will jump a 0.142 inches (3.6 mm) freebore just like a .38 Special fired from a .357 Magnum revolver. If the cartridge is not held by the extractor, the chances for a ruptured primer are great.[8] Smith & Wesson does make a double-action revolver that can fire either at will using moon clips. A single-action revolver in the .38–40 chambering can also be modified to fire the .40 or the 10mm if it has an extra cylinder. Some .40 caliber handguns can be converted to 9mm with a special purpose made barrel, magazine change, and other parts.[9][10]

Cartridge dimensions[edit]

The .40 S&W has 1.25 ml (19.3 grains H2O) cartridge case capacity.

![40 S&W maximum C.I.P. cartridge dimensions[2] All sizes in millimeters (mm).](https://upload.wikimedia.org/wikipedia/commons/thumb/e/ee/40_S%26W_Scale_Drawing.svg/400px-40_S%26W_Scale_Drawing.svg.png)

The common rifling twist rate for this cartridge is 406 millimetres (16.0 in), 6 grooves, ∅ lands = 9.91 ;mm, ∅ grooves = 10.17 mm, land width = 3.05 mm and the primer type is small pistol.[4] According to the official C.I.P. guidelines, the .40 S&W case can handle up to 225 megapascals (32,600 psi) piezo pressure. In C.I.P.-regulated countries every pistol/cartridge combo has to be proofed at 130% of this maximum C.I.P. pressure to certify for sale to consumers.

The SAAMI pressure limit for the .40 S&W is set at 241.32 megapascals (35,001 psi) piezo pressure.[11]

Performance[edit]

The .40 S&W cartridge has been popular with law enforcement agencies in the United States, Canada, and Australia. While possessing nearly identical accuracy,[12] drift and drop as the 9mm Parabellum, it also has an energy advantage[13] over the 9mm Parabellum[14] and .45 ACP,[15] and with a more manageable recoil than the 10mm Auto cartridge.[6] Marshall & Sanow (and other hydrostatic shock proponents) contend that with good jacketed hollow pointbullets, the more energetic loads for the .40 S&W can also create hydrostatic shock in human-sized living targets.[16][17]

Based on ideal terminal ballistic performance in ordnance gelatin during lab testing in the late 1980s and early 1990s, the .40 S&W earned status as “the ideal cartridge for personal defense and law enforcement”.[7][18] Apart from the imperfect relationship between ordnance gelatin ballistics and actual stopping power, critics pointed to the reduced power of the round compared with the 10mm Auto it was based on. Ballistically the .40 S&W is almost identical to the .38-40 Winchester introduced in 1874, as they share the same bullet diameter and bullet weight, and have similar muzzle velocities.[19] The energy of the .40 S&W exceeds standard-pressure .45 ACP loadings, generating between 350 foot-pounds (470 J) and 500 foot-pounds (680 J) of energy, depending on bullet weight. Both the .40 S&W and the 9mm Parabellum operate at a 35,000 pounds per square inch (240 MPa) SAAMI maximum, compared to a 21,000 pounds per square inch (140 MPa) maximum for .45 ACP.[20]

.40 S&W pistols with standard (not extended) double-stack magazines can hold as many as 16 cartridges. While not displacing the 9mm Parabellum, the .40 S&W is commonly used in law enforcement applications in keeping with its origin with the FBI. Select U.S. special operations units have available the .40 S&W and .45 ACP for their pistols. The United States Coast Guard, having dual duties as maritime law enforcement and military deployments, has adopted the SIG Sauer P229R DAK in .40 S&W as their standard sidearm.

The .40 S&W was originally loaded at subsonic velocity (around 980 ft/s (300 m/s)) with a 180 grains (11.7 g) bullet.[18]Since its introduction, various loads have been created, with the majority being either 155, 165 or 180 gr (10.0, 10.7 or 11.7 g).[21] However, there are some bullets with weights as light as 135 gr (8.7 g) and as heavy as 200 gr (13.0 g).[22]Cor-Bon and Winchester both offer a 135 gr (8.7 g) JHP and Cor-Bon also offers a 140 gr (9.1 g) Barnes XPB hollow-point. Double Tap Ammo, based out of Cedar City, Utah loads a 135 gr (8.7 g) Nosler JHP, a 155 gr (10.0 g), 165 gr (10.7 g) and 180 gr (11.7 g) Speer Gold Dot hollow-point (marketed as “Bonded Defense”), a 180 gr (11.7 g) Hornady XTP JHP, and three different 200 gr (13.0 g) loads included a 200 gr (13 g) Full Metal Jacket (FMJ), a 200 gr (13 g) Hornady XTP JHP and Double Tap’s own 200 gr (13 g) WFNGC (Wide Flat Nose Gas Check) hard cast lead bullet; the latter specifically designed for hunting and woods carry applications.

Case failure reports[edit]

The .40 S&W has been noted in a number of cartridge case failures, particularly in older Glock pistols due to the relatively large area of unsupported case head in those barrels, given its high working pressure.[23][24] The feed ramp on the Glock .40 S&W pistols is larger than on other Glocks, which leaves the rear bottom of the case unsupported, and it is in this unsupported area that the cases fail. Most, but not all, of the failures have occurred with reloaded or remanufactured ammunition.[25] Cartridges loaded at or above the SAAMI pressure, or slightly oversized cases which fire slightly out of battery are often considered to be the cause of these failures,[25] which are commonly referred to as “kaBooms” or “kB!” for short.[25] While these case failures do not often injure the person holding the pistol, the venting of high pressure gas tends to eject the magazine out of the magazine well in a spectacular fashion, and usually destroys the pistol. In some cases, the barrel will also fail, blowing the top of the chamber off.

M3 and M3A1 Grease Gun SMGs

M3 and M3A1 Grease Gun SMGs

M3 submachine gun

| Submachine Gun, Cal. .45, M3 | |

|---|---|

World War II-era Guide Lamp M3 submachine gun with 30-round magazine and other accessories. The Buffalo Arms bolt in this original M3 is dated January 1944.

|

|

| Type | Submachine gun |

| Place of origin | United States |

| Service history | |

| In service | 1943–1992 (US) Philippines (revived 2004) |

| Wars | |

| Production history | |

| Designer | George Hyde |

| Designed | 1942 |

| Manufacturer | General Motors, others |

| Unit cost | Approx. USD $15 (1943; equivalent to $208 in 2016)[5] |

| Produced | 1943–1945 |

| No. built | 622,163; 606,694 M3 15,469 M3A1 |

| Variants |

|

| Specifications | |

| Weight |

|

| Length | 29.8 in (760 mm) stock extended / 22.8 in (579.1 mm) stock collapsed |

| Barrel length | 8 in (203.2 mm) |

|

|

|

| Cartridge |

|

| Action | Blowback, open bolt |

| Rate of fire | 450 rounds/min cyclic |

| Muzzle velocity | 920 ft/s (280 m/s) |

| Effective firing range | Sights fixed to 100 yards (91 m)[6] |

| Feed system | 30-round detachable box magazine |

| Sights | Fixed rear peep sight and blade foresight, calibrated to 100 yards for caliber .45 M1911 ball ammunition[6] |

The M3 was an American .45-caliber submachine gun adopted for U.S. Army service on 12 December 1942, as the United States Submachine Gun, Cal. .45, M3.[6] The M3 was chambered for the same .45 round fired by the Thompson submachine gun, but was cheaper to produce, and lighter, although, contrary to popular belief, it was far less accurate.[6] This myth stems from a US army training film portraying the M3 as more accurate than its counterparts.[7] The M3 was commonly referred to as the “Grease Gun” or simply “the Greaser,” owing to its visual similarity to the mechanic’s tool.[8]

Intended as a replacement for the .45-caliber Thompson series of submachine guns, the M3 began to replace the Thompson in first-line service in mid-1944. Due to delays caused by production issues and approved specification changes, the M3 saw limited combat use in World War II and the M3A1 none.[6] The M3A1 was used in the Korean War and later conflicts.

Contents

[hide]

History[edit]

M3 in use in Brittany, France, August 1944

In 1941, the U.S. Army Ordnance Board observed the effectiveness of submachine guns employed in Western Europe, particularly the German 9×19mm MP 40 and British Sten guns, and initiated a study to develop its own Sten-type submachine gun in October 1942.[8]The Ordnance Department requested the army submit a list of requirements for the new weapon, and ordnance in turn received a separate list of requirements from both the infantry and cavalry branches for a shoulder-fired weapon with full- or semi-automatic fire capability in caliber .45 ACP or .30 Carbine.[6]

The two lists of requirements received by ordnance were then reviewed and amended by officials at Aberdeen Proving Ground. The amended requirement called for an all-metal weapon of sheet metal construction[9] in .45 ACP caliber, designed for fast and inexpensive production with a minimum of machining, and featuring a dual full-automatic and semi-automatic fire capability, a heavy bolt to keep the cyclic rate under 500rpm, and the ability to place 90 percent of all shots fired from a standing position in full-automatic mode on a 6×6 foot target at a range of 50 yards.[6] The benchmark for testing the M3’s performance would be the M1928A1 Thompson.[6]

George Hyde of General Motors‘s Inland Division was given the task of designing the new weapon, while Frederick Sampson, Inland Division’s chief engineer, was responsible for preparing and organizing tooling for production. The original T15 specifications of 8 October 1942 were altered to remove a semi-automatic fire function, as well as to permit installation of a kit to convert the weapon’s original .45 caliber to that of 9mm Parabellum.[6] The new designation for the 9mm/.45 full-automatic-only weapon was the T20.[6]

Five prototype models of the .45 T20 and five 9mm conversion kits were built by General Motors for testing. At the initial military trials, the T20 successfully completed its accuracy trials with a score of 97 out of 100.[6] In the endurance test, the test weapon fired more than 5,000 rounds of brass-case ammunition, with only two failures to feed.[6] Four army test boards composed of multiple army service branches independently tested and reviewed the T-20 prototype weapons including the Airborne Command, the Amphibious Warfare Board, the Infantry Board, and the Armored Forces Board.[6] All four branches reported malfunctions caused by the M3 magazine, mostly attributed to defective or jammed magazine followers.[6]

The T20 was formally approved by U.S. Army Ordnance for production at GM’s Guide Lamp Division in Anderson, Indiana in December 1942 as the U.S. Submachine Gun, Caliber .45, M3.[6] Guide Lamp produced 606,694 of the M3 variant submachine gun between 1943 and 1945.[6] Although reports of malfunctions caused by the single-feed magazine design appeared during the initial firing trials, no changes were made to the M3 magazine.[6]

Around one thousand M3 submachine guns in caliber 9mm Parabellum were built by Guide Lamp.[10] These original 9mm guns, identified by the markings “U.S. 9 mm S.M.G.” on the left side of the magazine well (without any model designation, such as M3), were delivered to the OSS in 1944. Additionally, Rock Island Arsenal and Buffalo Arms Corporation manufactured parts for a limited number of 9mm conversion kits for the M3.[11] Though 25,000 kits were originally requested for procurement, this was changed to a recommendation by the Ordnance Committee in December 1943 that only 500 9mm conversion kits be obtained.[11] Procurement was authorized in February 1944, but it is believed that only a limited number of kits were actually produced.[11] These conversion kits included a new 9mm barrel, replacement bolt and recoil springs, a magazine well adapter for use with British Sten gun 32-round magazines, and a replacement 9mm Sten magazine of British manufacture.[11] As the M3’s sights were not altered for the new cartridge, the 9mm M3 shot high at 100 yards, but the sighting error was deemed inconsequential. The OSS also requested approximately 1,000 .45-caliber M3 submachine guns with an integral sound suppressor (designed by Bell Laboratories). Specially drilled barrels and barrel nuts were manufactured by Guide Lamp, while the High Standard Firearms Company produced the internal components and assembled the weapon.[12] The Bell Laboratories suppressor was estimated to be only 80% as efficient as the British suppressed STEN Mk IIS.[13]

With its stamped, riveted, and welded construction, the M3 was originally designed as a minimum-cost small arm, to be used and discarded once it became inoperative.[14][15] As such, replacement parts, weapon-specific tools, and sub-assemblies were not made available to unit-, depot-, or ordnance-level commands at the time of the M3’s introduction to service.[16][17] In 1944, a shortage of M3 submachine guns created by the need for interim production changes forced U.S. Army Ordnance workshops to fabricate pawl springs and other parts to keep existing weapons operational.[14][18]

After its introduction to service, reports of unserviceability of the M3 commenced in February 1944 with stateside units in training, who reported early failure of the cocking handle/bolt retraction mechanism on some weapons.[6] Similar reports later came from U.S. forces in Britain who were issued the M3.[6] An investigation revealed several deficiencies in the construction of the M3’s bolt retraction mechanism, together with issues concerning barrel removal and retention as well as easily bent rear sights.[6] As a result, several product improvements were incorporated into all new M3 production, including a new design retracting pawl with improved heat treatment, a new spring stop fitted to the right-hand brace of the retracting lever, a modified ejector featuring a cocking lever trip, a larger ratchet pad with improved heat treatment to more securely retain the barrel assembly, and strengthening gussets fitted to the sides of the fixed ‘L’ rear sight.[6] After new complaints were raised about accidental magazine releases and failure of the wire buttstock to remain in place in the collapsed position, two additional changes were made to M3 production and approved by Ordnance on 31 August 1944.[6]This included a small sheet metal guard around the magazine release button, and the inclusion of a stop between the two rods forming the wire stock at the butt end.[6]

In December 1944, in response to field requests for further improvements to the basic M3 design, an improved, simplified variant of the M3 was introduced, the M3A1. 15,469 M3A1 submachine guns were produced before the end of World War II.[6]

It was originally hoped that the M3 could be produced in numbers sufficient to cancel future orders for the Thompson submachine gun, and to allow the army to gradually withdraw the more expensive Thompson from front-line service. However, due to unforeseen production delays and requests for modifications, the M3 never fully replaced the Thompson during World War II, and purchases of the Thompson continued until February 1944. A total of 622,163 M3/M3A1 submachine guns of all types were assembled by the end of World War II, by which time the Thompson, at over 1.5 million guns produced, outnumbered the M3 and M3A1 in service by a factor of nearly three to one.[6] The M3A1 did not see combat in World War II, but was used in Korea and Vietnam.[citation needed]

The M3 and M3A1 were largely withdrawn from U.S. frontline service beginning in 1959 and into the early 1960s, but continued to be used until the mid-1990s as on vehicle equipment aboard armored vehicles. During the mid 1970s tank drivers of the 1st Battalion 67th Armored attached to the 2nd Armored Division were issued the M3A1, because of its size and portability.[citation needed] During the Gulf War, drivers of the 19th Engineer Battalion attached to the 1st Armored Division were equipped with the M3A1 as part of their vehicle TOE.[citation needed] It was also the initial submachine gun equipping the Delta Force who prized it for its impressively quiet performance when equipped with a silencer.[19]

Design details[edit]

The M3 was an automatic, air-cooled blowback-operated weapon that fired from an open bolt. Constructed of plain .060-in. thick sheet steel, the M3 receiver was stamped in two halves that were then welded together.[6] The M3 was striker-fired, with a fixed firing pin contained inside the bolt. The bolt was drilled longitudinally to support two parallel guide rods, upon which were mounted twin return (recoil) springs. This configuration allowed for larger machining tolerances while providing operating clearance in the event of dust, sand, or mud ingress.[20] The M3 featured a spring-loaded extractorwhich was housed inside the bolt head, while the ejector was located in the trigger group.[21] Like the British Sten, time and expense was saved by cold-swaging the M3’s barrel.[6]

Operating mechanism[edit]

The M3 operating sequence is as follows: the bolt is cocked to the rear using the cocking handle located on the right side of the ejector housing. When the trigger is pulled, the bolt is driven forward by the recoil springs, stripping a round from the feed lips of the magazine and guiding the round into the chamber. The bolt then continues forward and the firing pin strikes the cartridge primer, igniting the round, resulting in a high-pressure impulse, forcing the bolt back against the resistance of the recoil springs and the inertial mass of the bolt. By the time the bolt and empty casing have moved far enough to the rear to open the chamber, the bullet has left the barrel and pressure in the barrel has dropped to a safe level. The M3’s comparatively low cyclic rate was a function of the relatively low pressure generated by the .45 ACP round, a heavy bolt, and recoil springs with a lighter-than-normal compression rate.[citation needed]

Features[edit]

The gun used metal stamping and pressing, spot welding and seam weldingextensively in its construction, reducing the number of man-hours required to assemble a unit. Only the barrel, bolt and firing mechanism were precision machined. The receiver consisted of two sheet metal halves welded together to form a cylinder. At the front end was a knurled metal cap which was used to retain the removable barrel. The cold-swaged, rifled barrel had 4 right-hand grooves. M3 and M3A1 submachine guns could be fitted with an optional, detachable flash hider, though none saw any service in World War II.[22] A later production flash hider designated Hider, Flash M9 was produced in time to see service during the Korean War. It proved popular in combat, as frequent night engagements emphasized the need to reduce flash signatures on small arms. In Korea, U.S. soldiers equipped with automatic weapons were taught to look above the flash of their weapon during night firing, a tactic that sometimes prevented the detection of crawling enemy infiltrators and sappers.[citation needed]

Projecting to the rear was a one-piece wire stock made from a formed steel rod that telescoped into tubes on both sides of the receiver. Both ends of the stock were tapped and drilled so that it could be used as a cleaning rod. It could also be used as a disassembly tool or as a wrench used to unscrew the barrel cap.[citation needed]

The M3’s cocking handle assembly was located on the right-hand side of the receiver on the ejector housing, just forward and above the trigger, and consisted of nine parts.[20] As the handle is pulled to the rear, a pawl rises to engage a notch in the bottom of the bolt, pushing the bolt to the rear until it locked back on the sear.

The fixed sights consisted of a rear aperture sight preset for firing at 100 yards (approximately 91 m) and a front blade foresight. All M3 submachine guns were test-fired for accuracy at a distance of 100 feet (30 m).[6] With the sights set at six-o’clock on a bullseye target, each gun was required to keep four out of five shots within or cut the edge of a three-inch (76 mm) bulls’ eye to meet accuracy requirements.[6]

The weapon’s only safety was the hinged ejection port dust cover. This cover had a projection on the underside that engaged a notch on the bolt, locking it in either its forward or rearmost positions. The M3 had no mechanical means of disabling the trigger, and the insertion of a loaded magazine would load the gun. With receiver walls made of relatively thin-gauge sheet metal, the M3/M3A1 were subject to disabling damage if dropped on an open dust cover – the covers bent easily, negating the safety feature. Dropping the gun on a sharp or hard surface could dent the receiver enough to bind the bolt.[citation needed]

The M3/M3A1’s 30-round magazine was the source of complaints throughout the service life of the weapon.[23][24] Unlike the Thompson, the M3 fed from a double-column, single-feed detachable box magazine which held 30 rounds and was patterned after the British Sten magazine; the single-feed design proved difficult to load by hand, and was more easily jammed by mud, dust, and dirt than double-column, double-feed designs like the Thompson.[25] Additionally, the feed lips of the single-feed design proved more susceptible to feed malfunctions when slightly bent or damaged. Plastic dust caps were later issued to cover the feed end of the magazine and keep out dust as well as protect the sensitive feed lips.[citation needed]

Variants[edit]

M3A1[edit]

In December 1944, a modernized version of the M3 known as the M3A1 was introduced into service, with all parts except the bolt, housing assembly, and receiver interchangeable with those of the M3. The M3A1 had several improvements:

- Most significantly eliminating the troublesome crank-type cocking lever assembly, replaced by a recessed cocking slot machined into the top front portion of the bolt, letting it be cocked by putting a finger into the cocking slot and pulling back the bolt.

- The retracting pawl notch was removed, and a clearance slot for the cover hinge rivets was added.

- The ejection port and its cover were lengthened to allow the bolt to be drawn back far enough to be engaged by the sear.

- The safety lock was moved further to the rear on the cover.

- To make loading the single-feed magazine easier, a magazine loading tool was welded to the wire stock; it also served as a cleaning rod stop.

- The barrel bushing received two flat cuts that helped in barrel removal by using the stock as a wrench.

- The barrel ratchet was redesigned to provide a longer depressing level for easier disengagement from the barrel collar.

- The spare lubricant clip (on the left side of the cocking lever assembly) was removed, replaced with an oil reservoir and an oiler in the pistol grip of the receiver assembly. The stylus on the oiler cap could also double as a drift to remove the extractor pin.

At 7.95 pounds empty, the M3A1 was slightly lighter than the M3, at 8.15 pounds empty, primarily due to the simplified cocking mechanism.[6] The M3A1 was formally approved for production on 21 December 1944.[6]

The M3A1 modifications resulted in a more reliable, lighter weight, easier to maintain, and easier to field strip submachine gun; the original M3 needed both the trigger guard removed and the cocking crank assembly detached from the receiver housing before unscrewing the barrel, but the M3A1 only required the user unscrew the barrel. To date, only one 9mm conversion kit for the M3A1 has been discovered.[11]

Because it had already been issued in large numbers, the existing M3 magazine design was retained, despite demonstrated deficiencies exposed during the weapon’s firing trials and its early combat service.[24] In an effort to improve reliability, a hard plastic Tenite cap designated T2 was adopted in November 1944 to fit over the feed lips of loaded magazines.[25] These caps protected the feed lips while keeping out dirt, sand, and debris.[26] Sometime during the 1960s the hard T2 plastic cap was replaced in service with one of pliant neoprene rubber, which could be removed with less noise.[27] Unfortunately, during service in the humid climate of Vietnam it was discovered that the rubber cap caused rust to form on the covered portion of the magazine, while causing loaded ammunition to corrode.[27]

Initially, M3 submachine guns returned for repair were not upgraded to the M3A1 standard, but merely inspected to ensure they had the improved M3 housing assembly and magazine release shield.[28] During the Korean War, existing M3 guns in service were converted to the improved M3A1 configuration using additional new production parts.[29] During the conversion, armorers frequently removed the M3 cocking handle, leaving the rest of the now-redundant cocking mechanism inside the subframe.[30] Overall, the M3A1 was seen by most soldiers and Ordnance technicians as an improvement over the M3. However, complaints of accidental discharge continued to occur even as late as the Korean War.[30] These incidents were sometimes caused by dropping the weapon on a hard surface with an impact sufficient to knock open the ejection port cover and propel the bolt backwards (but not enough to catch the sear). The return springs would then propel the bolt forward to pick up a cartridge from the magazine and carry it into the chamber, where the bolt’s fixed firing pin struck the primer upon contact.[30][31]

In 1945, the Guide Lamp factory manufactured 15,469 M3A1 submachine guns before production contracts were canceled with the end of the war. During the Korean War, Ithaca Gun Co built another 33,000 complete guns as well as manufacturing thousands of parts for the repair and rebuilding of existing M3 and M3A1 weapons.[32]

Foreign variants and derivatives[edit]

P.A.M. 1 & 2 (Argentina)[edit]

In 1954, a variant of the U.S. M3A1 submachine gun was designed at the Argentine FMAP (Fábrica Militar de Armas Portátiles) factory in the city of Rosario and put into production the following year as the P.A.M. 1 (Pistola Ametrelladora Modelo 1).[33][34] Constructed of somewhat thinner-gauge steel than the U.S. M3A1, the P.A.M. 1 was in essence a 7/8 scale replica of the U.S. weapon in 9mm Parabellum caliber,[35] but was lighter[36] and had a higher rate of fire. This was due to an incomplete transfer of all details to Argentina.[37] In service, the P.A.M. 1’s thinner sheet steel receiver tended to overheat with extended firing, while the gun itself proved somewhat more difficult to control in automatic fire despite the smaller caliber. Additionally, triggering the weapon to fire individual shots proved difficult owing to the increased rate of fire. Problems with accidental discharges and accuracy with the P.A.M. 1 led to an improved selective-fire version with a grip safety on the magazine housing known as the P.A.M. 2, first introduced in 1963.[37]

Colloquially referred to as La Engrasadora (the Greaser), 47,688 P.A.M. 1 and P.A.M. 2 submachine guns were produced between 1955 and 1972. A number of P.A.M. 1 and P.A.M. 2 submachine guns were used by the Argentine Army during the Falkland Islands War with the United Kingdom in 1982, and captured examples were tested by British military forces.[38]

Type 36 & 37 (China)[edit]

The Type 36 is a direct clone of the M3A1, manufactured in 1947 at the Shenyang Arsenal in Mukden.[39] It resembles a M3A1, except that it has no flats to allow the use of a wrench for easy removal and it has no oil bottle trap in the pistol grip.[39] Its parts are not interchangeable with the M3A1.[39]

10,000 Type 36s were made before they were obtained by pro-Communist forces in 1949.[39]

The Type 37 is a direct clone of the 9mm-chambered M3, made at the 60th Jinling Arsenal near Nanking.[39] Production continued in Taiwan as the Type 39, a successor to the Type 37.[39]

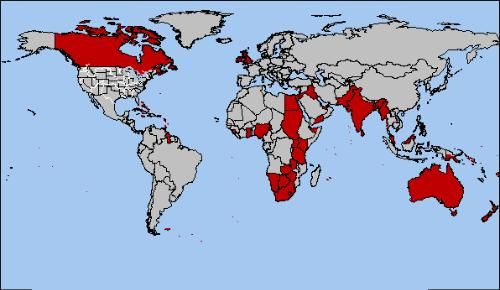

Users[edit]

Philippine Naval Special Warfare Group members conduct interdiction training with the U.S. Coast Guard in Cebu City, 2009. Two of them are armed with M3s.

Afghanistan[40]

Afghanistan[40] Argentina[41]

Argentina[41] Bolivia[42]

Bolivia[42] Brazil[citation needed]

Brazil[citation needed] People’s Republic of China: Copies made as the Type 36 and Type 37[39]and used in the Korean War by Chinese soldiers.[43]

People’s Republic of China: Copies made as the Type 36 and Type 37[39]and used in the Korean War by Chinese soldiers.[43] Republic of China[44]

Republic of China[44] Colombia: Used by the National Army of Colombia and the National Police of Colombia from the 1950s up to the 1970s, when it was replaced by the UZI submachine gun.[citation needed]

Colombia: Used by the National Army of Colombia and the National Police of Colombia from the 1950s up to the 1970s, when it was replaced by the UZI submachine gun.[citation needed] Dominican Republic[citation needed]

Dominican Republic[citation needed] Ecuador[42]

Ecuador[42] Greece Used by the Greek armed forces during World War II and the post-World War II period.[2]

Greece Used by the Greek armed forces during World War II and the post-World War II period.[2] Grenada[45]

Grenada[45] Guatemala[42]

Guatemala[42] Haiti[46]

Haiti[46] Japan: Used by the JSDF until the adoption of the Minebea PM-9.[47][48][49] Known to be used by JGSDF tank crews as a personal defense weapon. Still used in limited numbers in certain branches of the JSDF.[50]

Japan: Used by the JSDF until the adoption of the Minebea PM-9.[47][48][49] Known to be used by JGSDF tank crews as a personal defense weapon. Still used in limited numbers in certain branches of the JSDF.[50] Republic of Korea:[42] Mainly used by Republic of Korea Army Special Warfare Command.

Republic of Korea:[42] Mainly used by Republic of Korea Army Special Warfare Command. North Korea[51][unreliable source?]

North Korea[51][unreliable source?] Macedonia: 707 surplus M3 submachine guns were transferred to Macedonia in 1999.[42]

Macedonia: 707 surplus M3 submachine guns were transferred to Macedonia in 1999.[42] Mexico[citation needed]

Mexico[citation needed] Morocco: 1,472 surplus M3A1 submachine guns were transferred to Morocco in the 1990s.[52]

Morocco: 1,472 surplus M3A1 submachine guns were transferred to Morocco in the 1990s.[52] Philippine Commonwealth: Used by the Philippine Commonwealth Army, Philippine Constabulary and the Recognized Guerrillas during World War II under the Japanese Occupation from 1942 to 1945 and Post-War Era from 1945 to 1946.[citation needed]

Philippine Commonwealth: Used by the Philippine Commonwealth Army, Philippine Constabulary and the Recognized Guerrillas during World War II under the Japanese Occupation from 1942 to 1945 and Post-War Era from 1945 to 1946.[citation needed] Philippines:[42] Had their M3 submachine guns released from reserve stockpiles by the Philippine Navy for the Philippine Marine Corps‘s special forces due to budget constraints.[53] Modifications done on the refurbished weapons include an integral suppressor and a Picatinny rail.[54] The weapon had been tested with a prototype in May 2004.[53]

Philippines:[42] Had their M3 submachine guns released from reserve stockpiles by the Philippine Navy for the Philippine Marine Corps‘s special forces due to budget constraints.[53] Modifications done on the refurbished weapons include an integral suppressor and a Picatinny rail.[54] The weapon had been tested with a prototype in May 2004.[53] United States[1][42]

United States[1][42] South Vietnam[55][56]

South Vietnam[55][56]

Firearm Heresy & Blasphemy

Well here goes nothing and I suppose there will be a crowd in front of my house soon . Equipped with Torches, pitchforks, Tar. Feathers & of course a rail ready to go. But I have had a good life. So here we go.

On making your Guns Safer

I found this article on the net & since it’s better written than I could write. I thought I would share it with you!

Enjoy Grumpy

G&A Basics: How to Store Your Gun

Modern firearms are powerful tools that experienced shooters understand need to be treated with respect. While a gun is in use, we carefully follow a set of common sense rules to keep everyone safe. But how do we practice firearms safety when the shooting or hunting sessions are over? Most of the guns folks own will spend the majority of their working life at rest, placed in one state of storage or another, until the next shooting event. Since they remain powerful tools between trips to the range, it’s very important to store them properly.

A wide variety of safe gun storage accessories and containers are currently available. However, there is no universal solution to fill every role, or to fit every budget. Safe storage options are intended to perform one or more of the following tasks, which they do with varying degrees of effectiveness depending on how much money you’re willing to spend:

1. Prevent a gun from firing

2. Protect a gun from physical damage

3. Act as a theft deterrent

It’s much easier to consider the pros and cons of each storage system when they can be compared side by side. The following discussion is a walkthrough of the most common safe gun storage options, starting with the least expensive:

Trigger Locks ($0-$15):

Trigger locks fulfill a single safe gun storage objective: Prevent the gun from firing. Most new guns now arrive from the manufacturer with a trigger lock of some kind or other in the box. Trigger shoes clamp and lock around the trigger housing to prevent the trigger from being pressed. They should not be engaged on a loaded gun because they come in contact with the trigger as they are installed and removed. Cable locks allow the shooter to run cable through the barrel or action of a firearm. Since the cable blocks the action from being closed, the gun cannot be loaded or fired with the cable lock in place.

If these two lock options are not available, a simple household padlock can be looped over the trigger guard with the hasp set behind the trigger. This will prevent the trigger from completing a firing cycle. Although trigger locks are inexpensive (or even free), and can successfully prevent a gun from firing, they do nothing to protect the gun’s finish or to deter theft.

Soft-Side and Hard-Side Gun Cases ($10- $150):

Most sporting goods stores have entire aisles dedicated to affordable handgun, rifle, and shotgun cases. The options available range from padded fabric sleeves to rugged foam-lined plastic cases. The primary role of this kind of affordable carry case is to protect guns from physical damage. While they do a good job of preventing dings and scratches, their role as a security device is relatively limited.

Most soft and hard side cases can be “legally” locked for transport to and from the shooting range (check your local regulations). This could be a luggage lock through a soft case’s zipper pull, or a padlock through the handles of a hard case. This security system may be enough to keep small children out as well. However, the materials these cases are made of are easily defeated by ordinary edged implements. These low-cost cases also have a low theft deterrence value since they are light and easy to move. They have to be hidden or locked inside of another container to protect them from theft.

Strong Boxes and Metallic Gun Cases ($25 – $350):

In an effort to strike a balance between the security offered by a locking gun cabinet and the portability of a gun case, several companies offer portable strong boxes and metallic gun cases. Metal gun cases usually incorporate a reliable locking system or the means to attach heavy padlocks. Strong boxes, usually intended for handguns, offer mounting systems for permanent attachment to a fixed surface. Some boxes are fitted with quick-opening locking mechanisms, including electronic push-button access and fingerprint scanners.

Strong boxes and metallic gun cases are the first products discussed so far that start to fill all three mandates of a safe gun storage device. They can effectively protect against unauthorized access because of the difficulty in opening these units without a key or lock combination. These containers will effectively protect a gun’s finish from damage. And, if they can be attached or locked to a fixed object or surface, they offer some level of theft deterrence. But with features to fill all three mandates, the price starts to go up. It may be necessary to purchase batteries or extra mounting hardware to take advantage of all the storage device’s available features.

Locking Steel Gun Cabinets ($150 – $450):

Remember that grand wooden gun display case that your great-uncle had in his den? Looking through the engraved glass panes of the double doors, you could see his beautiful vintage shotgun collection. Sometimes he would retrieve that little brass key to open the doors so you could get a better look. While this kind of locking gun cabinet looks wonderful, it does not offer any truly viable level of safe gun storage, accept against small children. To secure firearms, a locking steel gun cabinet is a more secure choice.

Cabinets differ from gun safes in several respects. They follow a less-is-more design. The thinner gauge of steel, a simple locking mechanism, and the lack of fire-proofing insulation greatly reduces the cost. Because they are light enough to be safely carried by one or two people, they can be set up in apartment buildings or second-floor rooms where a gun safe would simply be too heavy or difficult to install.

Cabinets are a big step up from metallic gun cases or strong boxes when it comes to storing multiple firearms. They offer a much larger storage capacity and more configuration options. Cabinets can be securely bolted to a wall or to the floor. However, they do not offer the same level of theft deterrence as a gun safe. If you have the cash for a high-end cabinet, and the room to store it, you may want to spend a little more and purchase an economy-line gun safe.

Gun Safes ($500 – $2,500+):

Simply stated, gun safes are the most secure gun storage option available to the average gun owner. Even the basic units have terrific advantages over any of the other gun storage units described so far. A locked safe will definitely prevent a gun from being handled or loaded. The upholstered interior and built-in gun racks will help to protect the finish of the firearms while allowing air to circulate. And, best of all, they are an effective theft deterrent.

Much like automobiles or personal computers, gun safes are available with a wide variety of features, locking systems, and finishes, all of which affect the bottom line cost of the unit. These cost-changing features include the gauge (or thickness) of the steel used to construct the safe, the strength and reliability of the locking mechanism, the level of fire resistance (if any), the extent of the warranty, shelf and rack configuration options, as well as the color and quality options for the exterior finish.

Because all gun safes are relatively expensive (compared to other gun storage options) it makes sense to consider what you want very carefully before you buy. First-time safe buyers should be careful to avoid two common, but serious, mistakes. The first thing to avoid is buying a safe that’s too small. A unit that’s a perfect fit for your collection today may not serve your needs in ten years. A bit more expense up front may save you the trouble of changing out or adding a second safe down the road.

The second mistake is waiting too long to buy one. Yes, gun safes are big, heavy, difficult to install, and expensive to pay for. But they are well worth the trouble if you have a gun collection you care about. How do you know it’s time to invest in a gun safe? If the guns you have are worth more (sentimentally as well as financially) than the cost of the least expensive safe you would be willing to purchase, then it’s time to start shopping for one.

Read more: http://www.gunsandammo.com/home-featured/ga-basics-how-to-store-your-gun/#ixzz4sS9A84RB

Just Reach out & touch Someone!

M2 Browning

| Browning Machine Gun, Cal. .50, M2, HB | |

|---|---|

M2HB heavy machine gun

|

|

| Type | Heavy machine gun |

| Place of origin | United States |

| Service history | |

| In service | 1933–present |

| Used by | See Users |

| Wars | World War II Indonesian National Revolution Korean War First Indochina War Suez Crisis Portuguese Colonial War Vietnam War Six-Day War Iran-Iraq war Yom Kippur War Lebanese Civil War Colombian Internal Conflict Cambodian Civil War Cambodian-Vietnamese War Falklands War South African Border War Invasion of Grenada Bougainville Civil War[1] Invasion of Panama Persian Gulf War Somali Civil War Yugoslav Wars Kosovo War War in Afghanistan[2] Iraq War Mexican Drug War Syrian Civil War[3] Iraqi Civil War (2014-present)[4] Yemeni Civil War (2015–present)[5] Saudi Arabian-led intervention in Yemen[6] Conflict in Najran, Jizan and Asir |

| Production history | |

| Designer | John M. Browning |

| Designed | 1918[7] |

| Manufacturer | Current: General Dynamics, Fabrique Nationale, U.S. Ordnance, and Manroy Engineering (UK) Former: Sabre Defence Industries, Colt’s Patent Fire Arms Company, High Standard Company, Savage Arms Corporation, Buffalo Arms Corporation, General Motors Corporation (Frigidaire, AC Spark Plug, Saginaw Steering, and Brown-Lipe-Chappin Divisions), Kelsey Hayes Wheel Company, Springfield Armory, Wayne Pump Company, ERMCO, and Ramo Manufacturing, Rock Island Arsenal |

| Produced | 1921–present (M2HB) |

| No. built | 3 million[8] |

| Specifications | |

| Weight | 38 kg (83.78 lb) 58 kg (127.87 lb) with tripodand T&E |

| Length | 1,654 mm (65.1 in) |

| Barrel length | 1,143 mm (45.0 in) |

|

|

|

| Cartridge | .50 BMG (12.7×99mm NATO) |

| Action | Short recoil-operated |

| Rate of fire | 450-600 rounds/min (M2HB)[9][10] 750–850 rounds/min (AN/M2) 1,200-1,300 rounds/min (AN/M3) |

| Muzzle velocity | 2,910 ft/s (890 m/s) for M33 ball |

| Effective firing range | 1,800 m (2,000 yd)[9] |

| Maximum firing range | 2,500 m (2,700 yd) |

| Feed system | Belt-fed (M2 or M9 links) |

The M2 Machine Gun or Browning .50 Caliber Machine Gun is a heavy machine gun designed toward the end of World War I by John Browning. Its design is similar to Browning’s earlier M1919 Browning machine gun, which was chambered for the .30-06 cartridge. The M2 uses the much larger and much more powerful .50 BMG cartridge, which was developed alongside and takes its name from the gun itself (BMG standing for Browning Machine Gun). It has been referred to as “Ma Deuce”,[11] in reference to its M2 nomenclature. The design has had many specific designations; the official designation for the current infantry type is Browning Machine Gun, Cal. .50, M2, HB, Flexible. It is effective against infantry, unarmored or lightly armored vehicles and boats, light fortifications and low-flying aircraft. The M2 has been produced longer than any other machine gun.

The Browning .50 caliber machine gun has been used extensively as a vehicle weapon and for aircraft armament by the United States from the 1930s to the present. It was heavily used during World War II, the Korean War, the Vietnam War, the Falklands War, the Iraq War and the War in Afghanistan in the 2000s and 2010s. It is the primary heavy machine gun of NATO countries, and has been used by many other countries as well. The M2 has been in use longer than any other firearm in U.S. inventory except the .45 ACP M1911 pistol, also designed by John Browning.

The current M2HB is manufactured in the U.S. by General Dynamics[12] and U.S. Ordnance[13] for use by the U.S. government, and for allies via Foreign Military Sales, as well as foreign manufacturers such as FN Herstal.

Contents

[hide]

History[edit]

Machine guns were heavily used in World War I, and weapons of larger than rifle caliber were appearing. Both the British and French had large caliber machine guns. The larger rounds were needed to defeat the armor that was being introduced to the battlefield. Armor was also appearing in the skies. During World War I, the Germans introduced a heavily armored airplane, the Junkers J.I. The armor made aircraft machine guns using conventional rifle ammunition (such as the .30-06) ineffective.[14]

Consequently, the American Expeditionary Force‘s commander General John J. Pershing asked for a larger caliber machine gun.[15]Pershing asked the Army Ordnance Department to develop a machine gun with a caliber of at least 0.50 inches (12.7 mm) and a muzzle velocity of at least 2,700 feet per second (820 m/s).[14] U.S. Col. John Henry Parker, commanding a machine gun school in France, observed the effectiveness of a French 11 mm (0.43 in) incendiary armor-piercing round. The Army Ordnance Department ordered eight experimental Colt machine guns rechambered for the French 11 mm cartridge.[16] The French 11 mm round was found to be unsuitable because its velocity was too low. Pershing wanted a bullet of at least 670 gr (43 g) and a muzzle velocity of 2,700 ft/s (820 m/s). Development with the French round was dropped.[16]

Around July 1917, John M. Browning started redesigning his .30-06 M1917 machine gun for a larger and more powerful round. Winchester worked on the cartridge, which was a scaled-up version of the .30-06. Winchester initially added a rim to the cartridge because the company wanted to use the cartridge in an anti-tank rifle, but Pershing insisted the cartridge be rimless.[16] The first .50 machine gun underwent trials on 15 October 1918. It fired at less than 500 rounds per minute, and the muzzle velocity was only 2,300 ft/s (700 m/s). Cartridge improvements were promised.[17] The gun was heavy, difficult to control, fired too slowly for anti-personnel, and was not powerful enough against armor.[18]

While the .50 was being developed, some German T Gewehr 1918 anti-tank rifles and ammunition were seized. The German rounds had a muzzle velocity of 2,700 ft/s (820 m/s), an 800 gr (52 g) bullet, and could pierce [clarification needed]1 in (25 mm) at 250 yd (230 m).[19] Winchester improved the .50 caliber round to have similar performance. Ultimately, the muzzle velocity was 2,750 ft/s (840 m/s).[20]

Efforts by John M. Browning and Fred T. Moore resulted in the water-cooled Browning machine gun, caliber .50, M1921. An aircraft version was termed the Browning aircraft machine gun, caliber .50, M1921. These guns were used experimentally from 1921 until 1937. They had light-weight barrels and the ammunition fed only from the left side. Service trials raised doubts whether the guns would be suitable for aircraft or for anti-aircraft use. A heavy barrel M1921 was considered for ground vehicles.[21]

John M. Browning died in 1926. Between 1927 and 1932, Dr. S.H. Green studied the design problems of the M1921 and the needs of the armed services. The result was a single receiver design that could be turned into seven types of .50 caliber machine guns by using different jackets, barrels, and other components. The new receiver allowed right or left side feed. In 1933, Colt manufactured several prototype Browning machine guns (including what would be known as the M1921A1 and M1921E2). With support from the Navy, Colt started manufacturing the M2 in 1933.[22] FN Herstal (Fabrique Nationale) has manufactured the M2 machine gun since the 1930s.[23] General Dynamics, U.S. Ordnance, and Manroy Engineering (UK) are other current manufacturers.[citation needed]

A variant without a water jacket, but with a thicker-walled, air-cooled barrel was designated the M2 HB (HB for Heavy Barrel). The added mass and surface area of the heavy barrel compensated somewhat for the loss of water-cooling, while reducing bulk and weight: the M2 weighs 121 lb (55 kg) with a water jacket, but the M2 HB weighs 84 lb (38 kg). Due to the long procedure for changing the barrel, an improved system was developed called QCB (quick change barrel). The lightweight “Army/Navy” prefixed AN/M2 “light-barrel” version of the Browning M2 weighing 60 pounds (27 kg) was also developed, and became the standard .50-caliber aviation machine gun of the World War II-era for American military aircraft of nearly every type,[24] readily replacing Browning’s own air-cooled .30 caliber machine gun design in nearly all American aircraft installations.

Design details[edit]

The Browning M2 is an air-cooled, belt-fed machine gun. The M2 fires from a closed bolt, operated on the short recoilprinciple. The M2 fires the .50 BMG cartridge, which offers long range, accuracy and immense stopping power. The closed bolt firing cycle made the M2 usable as a synchronized machine gun on aircraft before and during World War II, as on the early versions of the Curtiss P-40 fighter.

The M2 is a scaled-up version of John Browning’s M1917 .30 caliber machine gun, even using the same timing gauges.

Features[edit]

The M2 has varying cyclic rates of fire, depending on the model. The M2HB (heavy barrel) air-cooled ground gun has a cyclical rate of 450-575 rounds per minute.[25] The early M2 water-cooled AA guns had a cyclical rate of around 450–600 rpm.[26] The AN/M2 aircraft gun has a cyclic rate of 750–850 rpm; this increases to 1,200 rpm or more for AN/M3 aircraft guns fitted with electric or mechanical feed boost mechanisms.[10] These maximum rates of fire are generally not achieved in use, as sustained fire at that rate will wear out the bore within a few thousand rounds, necessitating replacement. In addition to full automatic, the M2HB can be selected to fire single-shots or at less than 40 rounds per minute, or rapid fire for more than 40 rounds per minute. Slow and rapid firing modes use 5-7 round bursts with different lengths of pause between bursts.[27]

The M2 has an effective range of 1,830 metres (2,000 yd) and a maximum effective range of 2,000 metres (2,200 yd) when fired from the M3 tripod. In its ground-portable, crew-served role as the M2HB, the gun itself weighs 84 pounds (38 kg) and the assembled M3 tripod another 44 pounds (20 kg). In this configuration, the V-shaped “butterfly” trigger is located at the very rear of the weapon with a “spade handle” hand-grip on either side of it and the bolt release in the center. The spade handles are gripped and the butterfly trigger is depressed with one or both thumbs. Recently, new rear buffer assemblies have used squeeze triggers mounted to the hand grips, doing away with the butterfly triggers.

When the bolt release is locked down by the bolt latch release lock on the buffer tube sleeve, the gun functions in fully automatic mode. Conversely, the bolt release can be unlocked into the up position resulting in single-shot firing (the gunner must press the bolt latch release to send the bolt forward). Unlike virtually all other modern machine guns, it has no safety (although a sliding safety switch has recently been fielded to USMC armorers for installation on their weapons and is standard-issue for the U.S. Army for all M2s). Troops in the field have been known to add an improvised safety measure against accidental firing by slipping an expended shell casing under the butterfly trigger.[28] The upgraded M2A1 has a manual trigger block safety.

Because the M2 was intentionally designed to operate in many configurations, it can be adapted to feed from the left or right side of the weapon by exchanging the belt-holding pawls, and the front and rear cartridge stops (three-piece set to include link stripper), then reversing the bolt switch. The operator must also convert the top-cover belt feed slide assembly from left to right hand feed as well as the spring and plunger in the feed arm. This will take a well trained individual less than two minutes to perform.

The charging assembly may be changed from left to right hand charge. A right hand charging handle spring, lock wire and a little know how are all that are required to accomplish this. The M2 can be battle ready and easily interchanged if it is preemptively fitted with a retracting slide assembly on both sides of the weapon system. This eliminates the need to have the weapon removed from service to accomplish this task.

Ammunition[edit]

M2 Browning on a Samson RCWSof the Israel Defense Forces

There are several different types of ammunition used in the M2HB and AN aircraft guns. From World War II through the Vietnam War, the big Browning was used with standard ball, armor-piercing (AP), armor-piercing incendiary (API), and armor-piercing incendiary tracer (APIT) rounds. All .50 ammunition designated “armor-piercing” was required to completely perforate 0.875 inches (22.2 mm) of hardened steel armor plate at a distance of 100 yards (91 m) and 0.75 inches (19 mm) at 547 yards (500 m).[29] The API and APIT rounds left a flash, report, and smoke on contact, useful in detecting strikes on enemy targets; they were primarily intended to incapacitate thin-skinned and lightly armored vehicles and aircraft, while igniting their fuel tanks.[30]

Current ammunition types include M33 Ball (706.7 grain) for personnel and light material targets, M17 tracer, M8 API (622.5 grain), M20 API-T (619 grain), and M962 SLAP-T. The latter ammunition along with the M903 SLAP (Saboted Light Armor Penetrator) round can perforate 1.34 inches (34 mm) of FHA (face-hardened steel plate) at 500 metres (550 yd), 0.91 inches (23 mm) at 1,200 metres (1,300 yd), and 0.75 inches (19 mm) at 1,500 metres (1,600 yd). This is achieved by using a 0.30-inch-diameter (7.6 mm) tungsten penetrator. The SLAP-T adds a tracer charge to the base of the ammunition. This ammunition was type classified in 1993.[31][32]

When firing blanks, a large blank-firing adapter (BFA) of a special type must be used to allow the recoil operated action to cycle. This functions on the principle of a recoil booster, to increase the recoil force acting on the short recoil action. This is the exact antithesis of a muzzle brake. Without this adaptor, the reduced-charge blank cartridge would develop too little recoil to cycle the action fully. The adapter is very distinctive, attaching to the muzzle with three rods extending back to the base. The BFA can often be seen on M2s during peacetime operations.

Deployment[edit]

An M2 fired from a rigid-hulled inflatable boat.

B-25H “Barbie III” showing four M2 feeds and 75 mm M5 gun

The M2 .50 Browning machine gun has been used for various roles:

- A medium infantry support weapon

- As a light anti-aircraft (AA) gun in some ships; up to six M2 guns could be mounted on the same turret.

- As an anti-aircraft gun on the ground. The original water-cooled version of the M2 was used on a tall AA tripod or vehicle-mounted anti-aircraft weapon on a sturdy pedestal mount. In later variants, twin and quadruple M2HB Brownings were used, such as the M45 Quadmount (aka “meat chopper”) used on the US M16 half-track carrier. Twin or quad-mount .50 M2 guns normally used alternating left-hand and right-hand feed.

- Primary or secondary weapon on an armored fighting vehicle.

- Primary or secondary weapon on a naval patrol boat.

- Spotting for the primary weapon on some armored fighting vehicles.

- Secondary weapon for anti-boat defense on large naval vessels (corvettes, frigates, destroyers, cruisers, etc.).

- Coaxial gun or independent mounting in some tanks.

- Fixed-mounted forward-firing primary aircraft armament (AN/M2 and AN/M3 light-barrel versions only). The AN/M2 was used as primary armament in almost all World War II U.S. pursuit aircraft (such as the North American P-51 Mustang, Republic P-47 Thunderbolt, Lockheed P-38 Lightning, Bell P-39 Airacobra, Curtiss P-40 Warhawk, Grumman F6F Hellcat and Vought F4U Corsair). It was also used in fixed mountings in bombers and ground attack aircraft like the Douglas SBD Dauntless dive bomber, Grumman TBF Avengertorpedo bomber, and medium bombers such as North American B-25 Mitchell, Martin B-26 Marauder and Douglas A-26 Invader. The later, faster-firing electrically feed-boosted AN/M3 was used in many Korean War-era U.S.A.F.fighter aircraft such as the Lockheed F-80 Shooting Star, Republic F-84 Thunderjet, North American F-86 Sabre, and early versions of the Martin B-57 Canberra bomber. The US Navy had largely completed their move to the (unrelated) M2/AN 20mm autocannon for aircraft armament by this time.

- Turret-mount or flexible-mounted defensive armament, again only with the AN/M2 light-barrel version, in almost all US World War II-era bombers and patrol aircraft such as the Boeing B-17 Flying Fortress, Consolidated B-24 Liberator and Boeing B-29 Superfortress heavy bombers, North American B-25 Mitchell and Marin B-26 Marauder medium bombers, Consolidated PBY Catalina patrol flying boats, Grumman TBF/TBM Avenger torpedo bombers, and in a combined offensive/defensive turret mounting in many Northrop P-61 Black Widow night fighters. The AN/M3 was used as a flexible, quad-mounted, radar-directed tail-defence gun as late as 1980 on the Boeing B-52 Stratofortress, until replaced by 20mm M61 Vulcan Gatling type cannon

- Variants of the AN/M3 are used as flexible door guns or as flexible remotely-controlled armament subsystems on many US Army, Navy, Marine Corps and Coast Guard helicopters, such as the Bell UH-1 Iroquois, Sikorsky UH-60 Blackhawk and variants, Sikorsky CH-53E Super Stallion, Bell OH-58 Kiowa and others.

United States[edit]

A U.S. soldier in Normandy stands guard with the M2HB installed on a dual-purpose mounting.

At the outbreak of the Second World War the United States had versions of the M2 in service as fixed aircraft guns, anti-aircraft defensive guns (on aircraft, ships, or boats), infantry (tripod-mounted) guns, and as dual purpose anti-aircraft and anti-vehicular weapons on vehicles.[33][34]

The .50 AN/M2 light-barrel aircraft Browning used in planes had a rate of fire of approximately 800 rounds per minute, and was used singly or in groups of up to eight guns for aircraft ranging from the P-47 Thunderbolt to the B-25 Mitchellbomber, which in the last J-version of the Mitchell could have up to fourteen M2s firing forward for ground attack missions – eight in a solid metal-structure nose, four more mounted in a pair of conformal twin-gunned gun pods on the lower cockpit sides, and two more if the forward dorsal turret’s pair of M2 guns were also aimed straight forward.

In the dual-purpose vehicle mount, the M2HB (heavy barrel) proved extremely effective in U.S. service: the Browning’s .50 caliber AP and API rounds could easily penetrate the engine block or fuel tanks of a German Bf 109 fighter attacking at low altitude,[35] or perforate the hull plates and fuel tanks of a German half-track or light armored car.[29][36][37] While the dual-purpose mounting was undeniably useful, it did normally require the operator to stand when using the M2 in a ground role, exposing him to return fire.[38] Units in the field often modified the mountings on their vehicles, especially tanks and tank destroyers, to provide more operator protection in the anti-vehicular and anti-personnel role.[39] The weapon was particularly hated by the Germans, whose attacks and ambushes against otherwise helpless stalled motor convoys were frequently broken up by .50 caliber machine gun fire.[40][41] Vehicles would frequently “recon by fire” with the M2 Browning, i.e. they would fire continuously at suspected points of ambush while moving through areas still containing enemy forces. One vehicle would fire exclusively to the right, the following vehicle to the left, the next one to the right, and so on in order to cover both flanks of the advancing convoy.

Besides vehicle-mounted weapons, the heavy weapons companies in a World War II U.S. Army infantry battalion or regiment were each issued one M2 Browning with tripod (ground) mount.[42] Mounted on a heavily sandbagged tripod, the M2HB proved very useful in either a defensive role or to interdict or block road intersections from use by German infantry and motorized forces.[43] Hearing the sound of an M2 could often cause enemy infantry to take cover.[44] There are numerous instances of the M2 Browning being used against enemy personnel, particularly infantry assaults[45] or for interdiction or elimination of enemy artillery observers or snipers at distances too great for ordinary infantry weapons.[46][47][48]

An M2 overlooking the Korengal Valley at Firebase Phoenix, Afghanistan, in 2007

The M2HB was not widely used in the Pacific campaign for several reasons, including the weight of the gun, the nature of infantry jungle combat, and because road intersections were usually easily outflanked.[49] However, it was used by fast-moving motorized forces in the Philippines to destroy Japanese blocking units on the advance to Manila.[43] The quad mount .50 was also used to destroy Japanese emplacements.[50]

The M2HB was used in Korea and Vietnam, and later in both Operation Desert Storm, the Afghan theater of Operation Enduring Freedom and in Iraq. In 2003, U.S. Army SFC Paul Ray Smith used his M2HB mounted on an M113 armored personnel carrier to kill 20 to 50 enemies who were attacking a U.S. outpost, preventing an aid station from being overrun and allowing wounded soldiers to be evacuated,[51] SFC Smith was killed during the firefight and was posthumously awarded the Medal of Honor.

M45 Quadmount[edit]

The M45 Quadmount was a mounting of four .50 M2HB guns with a single gunner situated behind an armored housing. This was used by U.S. AA battalions, fitted either on a towed trailer or mounted in a half-track carrier (M16 AA half-track). With 200 rounds per gun in a powered tracking mount, the guns proved very effective against low-flying aircraft. The use of four guns adequately compensated for the fact that the individual M2HB’s rate of fire (450-550 rounds per minute) was low for an effective anti–aircraft weapon.[52]

Towards the end of the war, as Luftwaffe attacks became less frequent, the quad .50 (nicknamed the Meat Chopper or Krautmower[52]) was increasingly used in an anti-personnel role, similarly to the earlier-introduced (1940) and more powerful — but much more difficult to keep well-fed with ammunition when in action — German 20 mm Flakvierling. Snipers firing from trees were engaged by the quad gunner at trunk level – the weapon would cut down and destroy the entire tree, and the sniper with it.[44][50]

The M45 Quadmount was still in use during the Vietnam War.

Commonwealth and other forces[edit]

Commonwealth use of the M2 Browning .50 caliber machine gun (known as the .5 Browning in British and Commonwealth service) was limited in World War II, though from 1942 it was standard armament on US-built AFVs provided under lend-lease such as the M4 Sherman, M7 Priest, M8 Greyhound, or M10 tank destroyer variously used by British, Canadian, Australian, South African and New Zealand units. Nevertheless, the heavy Browning’s effectiveness was praised by many British and Commonwealth soldiers in infantry, armored, and ordnance branches.[53][54] Many commanders thought that the .50 Browning the best weapon in its class, certainly the best of the American weapons, including the M1 Garand and M1 Carbine.[54][55] In North Africa, after Commonwealth units began to obtain sufficient parts, manuals, gauges, and ammunition for the new weapon, the .50 Browning was increasingly used, eventually replacing the 15 mm Besa,[54]but in Italy it was often deleted from top turret mountings because the mount exposed the operator to low branches and enemy fire.[56] All LRDGs, and some SAS units used the aircraft (AN/M2) version of the gun, while beam/waist-mounted and turret-mounted Brownings were used later in the war in such aircraft as the Short Sunderland and Lancaster bomber.

After World War II, the .50 Browning continued to see action in Korea and other theaters, in aircraft, tripod (ground), ground AA (hip-ring), and vehicle mounts. One of its most notable actions in a ground role was in a fierce battle with a nine-man SAS team at the Battle of Mirbat in Oman in July 1972, where the heavy Browning and its API ammunition was used to help repulse an assault by 250 Yemeni Adoo guerrillas, though the more famous weapon from the battle is a 25 pounder gun.[57]

A .50 caliber Browning was installed along with a .30 caliber Browning machine gun in each compact one-man turret on M113 APCs used by the Royal Australian Armoured Corps in South Vietnam.

The M2HB has been in service with the Israel Defense Forces since its establishment and has served in all of Israel‘s wars, operations and conflicts. In 2012 the IDF upgraded its M2HB machine guns to the M2HQCB model, with heavy quick change barrel.[58] Today the M2 serves as an infantry crew-served heavy machine gun, as a remote-controlled external coaxial gun on Merkava main battle tanks, as the main weapon on the Samson RCWS and as a secondary weapons on Israeli Sea Corps gunboats and missile boats.

Nigerian troops have extensively deployed the 50 caliber Browning, mounted on Otokar Cobra APCs, Panhard VBL M11s and Landcruiser gun-trucks in counterinsurgency operations in the Niger Delta, N.E Nigeria, the Jos Plateau and in Mali

M2 as a sniper rifle[edit]

The M2 machine gun has also been used as a long-range sniper rifle, when equipped with a telescopic sight. Soldiers during the Korean War used scoped M2s in the role of a sniper rifle, but the practice was most notably used by US Marine Corps sniper Carlos Hathcock during the Vietnam War. Using an Unertltelescopic sight and a mounting bracket of his own design, Hathcock could quickly convert the M2 into a sniper rifle, using the traversing-and-elevating (T&E) mechanism attached to the tripod. When firing semi-automatically, Hathcock hit man-size targets beyond 1,800 metres (2,000 yd)—twice the range of a standard-caliber sniper rifle of the time (a .30-06 Winchester Model 70). In fact, Hathcock set the record for the longest confirmed kill at 2,250 metres (2,460 yd), a recordwhich stood until 2002, when it was broken in Afghanistan by Canadian Army sniper Arron Perry.[59][60]

Geneva Convention use misconception[edit]