This is a Potently Powerful Package. It can be Pleasurable or Painful, it comes at a Premium Price, and it’s even Purty. It’s the latest candidate for the title of Perfect Packin’ Pistol. The cartridge it houses is Proprietary and the sixgun itself will last in Perpetuity. This Phenomenon is the latest sixgun/cartridge combination from Freedom Arms, the .500 Wyoming Express. Perfect Packin’ Pistols are highly Personal and very dependent upon the Perception of just what is Perfect and quite often dependent upon the user’s locality. For anyone looking for the most Power Per Pound of Packing weight, this is it!

Since 1983, Freedom Arms has been producing the finest single-action sixguns to ever come from a factory. In the early 1980s, Wayne Baker and Dick Casull came together to produce not only the finest single action ever manufactured but the most powerful as well. That sixgun was the Freedom Arms .454 Casull. Both the sixgun and cartridge were destined to change the sixgunning

scene drastically. The .357 Magnum had arrived in 1935 heralded as the world’s most powerful revolver, unable to be handled by mere mortals. Twenty years later the .44 Magnum arrived pushing a bullet 100 grains heavier at the same speed of the early .357 Magnum loads. As a teenager I fired an early 4″ Smith & Wesson .44 Magnum with Remington factory loads and from my perspective then, I could not see any way I could ever handle one. It was a long learning process as I grew older.

While our early heroes were experimenting with heavy .44s in various forms, Dick Casull was experimenting with the .45 Colt. Casull started using heavy loads in the then new solid head .45 Colt brass in Colt Single Actions. When he soon discovered his loads where too heavy for production Colts, he started making his own fiveshot cylinders.

It did not take long to get past the safety factor and he soon decided to build his own larger, stronger revolver. He not only entered new levels of sixgun power he also disproved the old myth of .45 Colt brass being weak. However, when his .454 Magnum became reality the .45 Colt case was lengthened to prevent any of these heavy loads entering the chambers of older .45 sixguns, especially black-powder guns where the results would be decidedly disastrous.

The Beginning

In the 1970s a very few .454 Casull chambered five-shot revolvers were produced by North American Arms, however it remained for Wayne Baker to form Freedom Arms and really begin producing what is now known as the Model 83 revolver. From the very first, these premium quality, five-shot, stainless steel sixguns were built with the best materials and exceptionally tight tolerances to be able to handle the power of the .454 Casull. In those days it was not easy to convince many writers to even try the .454. It gives me great pleasure to have been one of the first to spotlight the .454 as well as provide extensive loading data in Handgunner in the mid-1980s. It took awhile for the shooting public to discover the .454 and Freedom Arms went from a vault full of sixguns looking for owners to a back order situation. Handgun hunters especially, went for the .454 in a big way.

Freedom Arms did not stop with the .454 Casull-chambered Model 83. They soon offered their premium revolver in .44 Magnum, .357 Magnum, .41 Magnum and even the greatest of all cartridges, the .22 Long Rifle. A very few were even chambered in .50 Action Express. While Freedom Arms was producing those first .454s, John Linebaugh was experimenting with even larger calibers first using cut down .348 Winchester for his .500 Linebaugh (see The Sixgunner in this issue), which was followed up by the .475 Linebaugh using .45-70 brass. In the 1990s, Bob Baker of Freedom Arms took a good look at the .475 for chambering in the Model 83, however the rims were too large to fit the five shot cylinders of their production revolvers.

Baker experimented with the .475 by reducing the diameter of the parent .45-70 brass rims and found the cartridge would perform exceptionally well in the Model 83. However, he did not wish to produce a revolver for which shooters could not obtain factory loaded ammunition or at least factory brass of the proper dimensions. When loaded ammunition arrived from Buffalo Bore as well as factory brass from Starline, the Model 83 was chambered in .475 Linebaugh and to this day sixgunners still argue over which is more powerful, the .454 or the .475 Linebaugh. My answer in these types of situations is always “Buy ’em both!”

The next natural step up in caliber was the .500. However, this cartridge is so large that even by trimming the rim it was impossible to make it fit the Freedom Arms cylinder without also altering the cylinder ratchet. Baker hit on the answer and showed me the cartridge nearly two years ago. Meanwhile, Baker spent a long time experimenting with loads, tweaking the brass, and as he reached the top level of power possible with the new cartridge, he told me “I’m getting too old for this!” That should tell you something about the power possible in the new .500 Wyoming Express as Bob Baker handles the .454 Magnum like it’s a .44 Special.

To solve the problem of cylinder size the Wyoming Express uses a belted case. Baker says of the new cartridge: “The .500 WE is a proprietary cartridge of Freedom Arms, Inc. using a 1.370″ length belted case. The belt provides reliable head spacing on a small shoulder which was required to work in the Freedom Arms Model 83 revolver. It also uses a .500″ diameter bullet with a maximum nose length of .395″ which gives a maximum overall cartridge length of 1.765″.

The cartridge was designed to not only get outstanding and predictable ballistic performance but to also minimize forcing cone erosion, thereby extending the useful life of your Freedom Arms revolver. This is done by matching powder column length, powder volume and bullet diameter to an expected range of bullet weights, velocity ranges and pressure levels.

Notice a couple of things here when comparing the .500 Wyoming Express to the .500 Linebaugh which inspired it. The .500 Linebaugh uses a large rim, the .500 Wyoming Express head spaces on a belt. The .500 Linebaugh brass is 1.400″ while the .500 WE is set at 1.370″. Bullets are not interchangeable with the .500 Linebaugh using .511″ diameter bullets and the .500 Wyoming Express designed for the use of true 1/2″ diameter bullets.

Strong Spirit/Weak Flesh

When Bob Baker first provided me with his experimental loading data for the .500 Wyoming Express with 350- and 370-grain bullets at 1,600 fps, 400s at 1,500 fps, and 440s at 1,400 fps (Freedom Arms will supply this data with their revolver) I remembered his

comment of “I’m too old for this!” I responded with “How do you think I feel with about two decades on you?” I knew there was no way I was about to be able to handle the heaviest loads in the .500 Wyoming Express. Twenty years ago, maybe; today, no way!

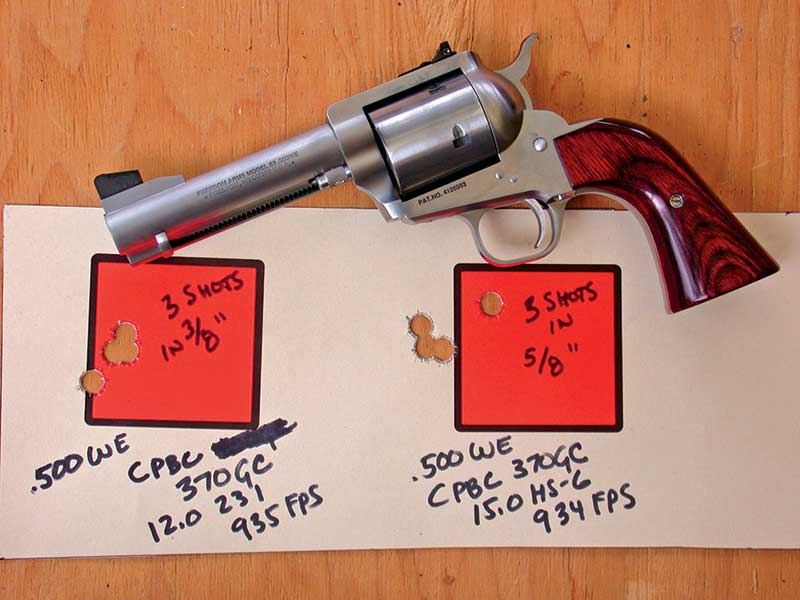

My heaviest loads just topped 1,200 fps and while manageable in a 71⁄2″, scope-sighted Model 83, they were brutal in the relatively lightweight 43⁄4″ version. The heaviest loads I used in the Perfect Packin’ Pistol 43⁄4″ Model 83 was the Cast

Performance Bullet Co.’s 440-grain Hard Cast Gas Checked LBT over 19 grains of Blue Dot for 1,201 fps in the 71⁄2″ version and 1,143 fps in the short barreled PPP. In the latter I was able to put three shots in 7/8″ at 20 yards and there is nothing I

am ever likely to encounter in the game fields I cannot take cleanly and completely with this load.

As I was testing both sixguns, my loads, and myself with the .500 Wyoming Express I thought of Elmer Keith and Tom Ferguson. When Keith finally got his much awaited .44 Magnum after 30 years of urging of manufacturers on his part, he reported in 1957 he had fired 600 rounds the first year; I fired more .500s than that from the Freedom Armsrevolvers in three days.

When Ferguson tested the .500 Linebaugh many years ago he fired a one-shot group and said that was enough. Both were smarter men than I am! Believe me even with the “lighter” loads the .500 WE recoils more, much more, than comparable revolvers chambered in .44 Magnum.

Test Guns

My pair of test guns were a brand new 43⁄4″ Freedom Arms Model 83 chambered in .500 Wyoming Express and my 71⁄2″ Model 83 .50 Action Express which was returned to the factory to have a second cylinder fitted in .500 WE. While it was there I had Freedom Arms fit an SSK T’SOB scope base as there is no other I will trust with really hard kicking revolvers. For a scope I chose a Leupold, as I’ve had excellent results with their products on hard kicking sixguns and single shot pistols for more than two decades. In this case the choice was one of their silver, 4X long eye relief scopes mounted with three rings on the T’SOB base.

Any Model 83 originally chambered in .50 AE can be retrofitted with a .500 WE cylinder, however at least at this time Freedom Arms is not offering the .50 AE cylinder as an option with the .500 Wyoming Express.

Freedom Arms is also offering the .500 Wyoming Express brass in plastic cartridge boxes holding 64 rounds as well as RCBS loading dies. The carbide three die set includes a special die setting gauge which is actually a washer which will place the carbide sizer at the proper position to not engage the belt on the cartridge case when full-length sizing. This washer is placed on top of the shell holder and the sizing die is then screwed down until it meets the washer. Once this is accomplished there is no danger of squeezing the belt, which would result in poor head spacing and possible misfires. Freedom Arms recommends seating and crimping in two separate operations so it would be handy to have a second sizing-crimping die.

For my loading of the .500 Wyoming Express I used four hard cast gas checked designs, Oregon Trails’ 370, and from Cast Performance Bullet Co. came 370, 400, and 440 LBT bullets. For jacketed bullets my choice was Sierra’s 350 JHP and 400 JFN. These were originally designed for the .500 S&W Magnum and when seated normally in the center of the cannelure that serves as a crimping groove will protrude from the front of the Freedom Arms cylinder.

I was able to use them by crimping at the very top of the crimping groove, however Sierra will be offering .500 WE versions with the cannelure set a little higher. Even in my hands the .500 WE has proven to be exceptionally accurate. The scope-sighted 71⁄2″ version is an excellent choice for the hunting of big, heavy, mean, nasty critters, while many will find the 43⁄4″ version to be the Perfect Packin’ Pistol. Should I dare to roam among mean nasty critters looking to end my sojourn here I would certainly load it to full horsepower. If needed, I doubt I would even feel the recoil! I like ’em both.

For more info:

Freedom Arms, P.O. Box

150, Freedom, WY 83120,

(307) 883-4432,

www.freedomarms.com

Leupold,

14400 NW Greenbrier Pkwy,

Beaverton, OR 97006,

(503) 646-9171

www.leupold.com