The pain and weakness of arthritis can be debilitating in firearms handling, particularly when it comes to loading and unloading semi-automatic handguns. In this article, we’ll offer some tips and specific products that you may find helpful. But first, a couple of caveats: First, this information is in no way meant to replace the advice of your doctor. Furthermore, the equipment modifications mentioned here are suggestions, and should only be taken as such. We’re neither endorsing nor guaranteeing that these adaptations are possible for all pistols. Your best course of action is to consult with a qualified gunsmith about the applicability of these to a specific firearm.

Loading the magazine

Consider the strength and dexterity required when loading—fully loading—a double-stack magazine. The resistance generated by the magazine spring may start lightly, but by the time there are 10 to 12 rounds in the magazine it becomes nearly insurmountable. The force needed to compress the spring must be generated by pressing the rim of the case head of the round to be loaded into the body of the round already inserted into the magazine. This relies heavily on the strength and stability of the thumbs, which, under ideal conditions, is a good idea. Unfortunately, the most common site of arthritic impairment in the hand is the large joint (carpometacarpal) at the base of the thumb. The average speed loader may help, but most shooters continue to rely on at least one thumb to generate the pressure to depress the round in the magazine.

Equipment suggestion: The Uplula by Maglula, LTD all but eliminates the fine motor element of the task. This device utilizes the stronger gross movement of whole-hand gripping to compress the magazine spring.

Racking the slide

Stacking a full magazine in a semi-automatic is only one step toward the goal of loading the pistol. Racking the slide to move the first round out of the magazine and into the chamber is the second goal. This task can be modified through changes in technique or equipment. The overhand grip technique minimizes joint stress and increases muscle activation by using nearly the entire hand to grasp the slide. For the right-handed shooter, that means resting the left hand across the back of the slide, making sure to stay clear of the ejection port. Grip force is multiplied by placing the finger tips and the base of the palm over the cocking serrations on either side of the slide. Part of this technique is to not rely solely on the left hand (in this example) to move the slide rearward. Make the movement a combined action by also driving the right hand forward. This way, the larger muscle groups of the chest, shoulders and arms can be brought into play.

Unfortunately, even the best techniques have limitations when pain enters the picture. Fortunately, equipment adaptations can often close that gap.

Equipment suggestion: The “Halo” charging ring for Browning Buckmark. The charging ring is an extension mounted to the rear of the slide that provides an alternative contact point for cycling the firearm. With this design, the user can slip a finger through the ring, and with the combined motion of pushing with the firing hand, and pulling rearward with the support hand, he or she can achieve slide motion. There are multiple manufacturers, including those made for many other popular pistols. This is but one example that fits a popular .22-caliber gun.

Equipment suggestion: The Handi-Racker. This device is a thick plastic card with an indentation cut into one side that fits over the muzzle end of the slide and accommodates the barrel protruding as the slide retracts. With the Handi-Racker in place, the user would press the end of the device against a fixed surface, which would drive the slide back. The main drawback is that you are pointing the muzzle of the firearm into a fixed surface—a wall, table or post—which may not constitute a safe direction. That requires constant user diligence to assure compliance with safe gun handling standards.

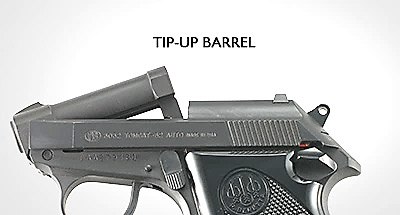

One final equipment suggestion: The final and ultimate gear modification is always to use a different type of pistol. Beretta eliminated the need for racking the slide by producing a family of break-action semi-automatics beginning in the 1950s. Since then the design has been copied by other manufacturers, but we will give Beretta its due here. The Beretta 3032 Tomcat, 950, 21A Bobcat and the Cheetah models all use a tip-up barrel design for loading the first round into the chamber. This makes it possible to have a fully loaded pistol without ever having to manipulate (rack) the slide. These pistols are quite small, work well for concealed carry purposes, and can be chambered in .22 Short, .22 LR, .25 ACP, .32 ACP and .380 ACP.

Do keep in mind that the same characteristics that make these firearms good for concealed carry also tend to make them poor options for plinking at the range. Their diminutive size can make gripping and recoil management difficult for a person with arthritis. Since the slide operates on a blow back mechanism, it may operate stiffly, creating challenges to manually cycle the slide to clear a malfunction or check for a barrel obstruction.